3-33

3

Servicing Right-Side

Components

NOTE: Whenever a part is worn excessively,

cracked, damaged in any way, or out of tolerance,

replacement is necessary.

INSPECTING CENTRIFUGAL

CLUTCH SHOE

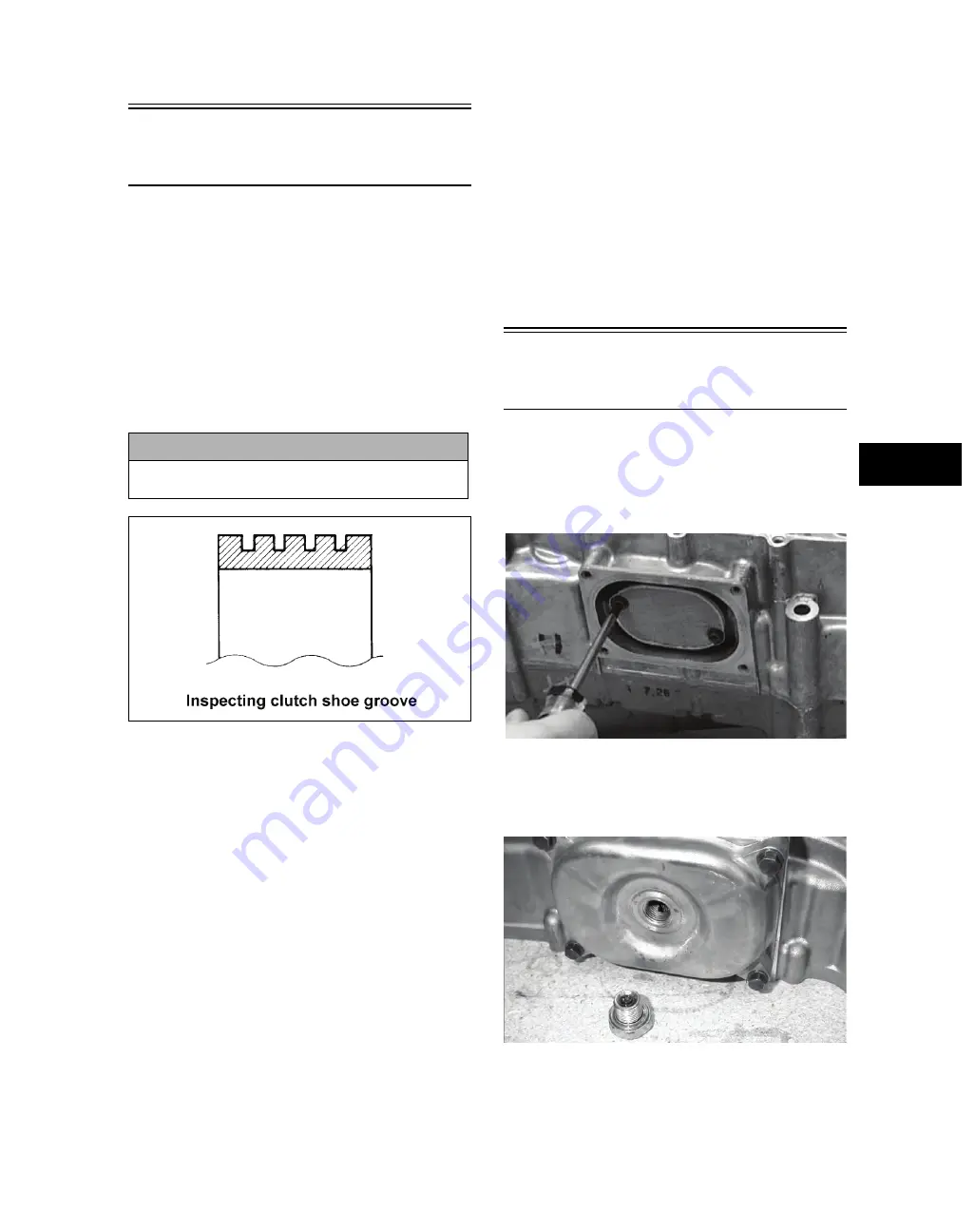

1. Inspect the clutch shoe for uneven wear, chips,

cracks, or discoloration.

2. Inspect the depth of the grooves in the clutch

shoes. If any shoe is worn to the bottom of the

groove, replace the complete set.

ATV1014

INSPECTING CENTRIFUGAL

CLUTCH HOUSING

1. Inspect the clutch housing for burns, marks, scuffs,

cracks, scratches, or uneven wear.

2. If the housing is damaged in any way, the housing

must be replaced.

INSPECTING PRIMARY

ONE-WAY DRIVE

1. Insert the drive into the clutch housing.

2. Rotate the inner race by hand and verify the inner

race rotates only one direction.

3. If the inner race is locked in place or rotates both

directions, the drive assembly must be replaced.

INSPECTING OIL PUMP

1. Inspect the pump for damage.

2. It is inadvisable to remove the screw securing the

pump halves. If the oil pump is damaged, it must

be replaced.

NOTE: The oil pump is a non-serviceable compo-

nent and must be replaced as a complete assem-

bly.

DRIVEN PULLEY ASSEMBLY

NOTE: The driven pulley assembly is a non-ser-

viceable component and must be replaced as a

complete assembly.

Installing Right-Side

Components

A. Oil Strainer/Oil Pump

1. Place the oil strainer into position beneath the

crankcase. Tighten the Phillips-head screws

(coated with red Loctite #271) securely.

MD1337

2. Place the strainer cover into position on the crank-

case making sure the O-ring is properly installed

and secure with the four cap screws; then tighten

the oil drain plug to 20 ft-lb.

MD1208

3. Place two alignment pins and the oil pump into

position on the crankcase and secure with the Phil-

lips-head screws coated with blue Loctite #243.

Tighten to 8 ft-lb.

! CAUTION

Always replace clutch shoes as a complete set or

severe imbalance could occur.

Summary of Contents for MXU 450i

Page 17: ...Oil level stick...

Page 23: ...Low range High range Neutral Reverse...

Page 25: ...1 mm 0 039 in...

Page 126: ...A B...

Page 127: ...LCD Gauge Connector LCD Gauge Connector...

Page 134: ...9 4 NOTES...

Page 135: ......