7-2

7

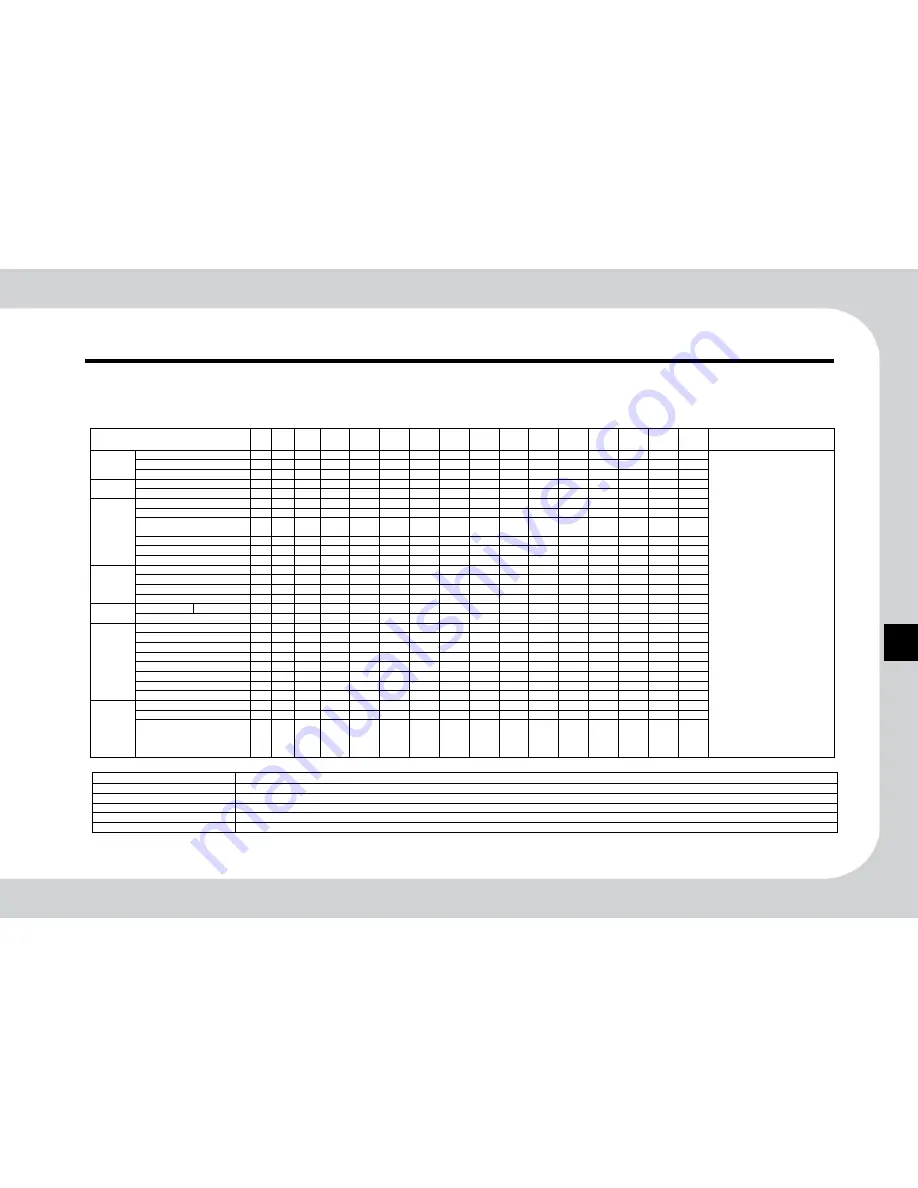

Overview of Regular Maintenance for Hazard Reduction

Perform periodical check-up and maintenance as scheduled to ensure riding safety, vehicle performance and prolonged service life.

Periodical Check-up Items and Scheduling of the Exhaust Control System:

I: Inspection; clean, lubricate, replenish, remedy or replace as required. A: Adjustment. C: Cleaning. R: Replace. T: Tightening. M: Maintenance. D: Diagnosis

Mileage

Task

300 1000 2000 3000

4000

5000

6000

7000

8000

9000 10000 11000 12000 13000 14000 15000 Remarks

Lubrication

System

Engine Oil

R

R

R

R

R

R

R

R

R

I: Check-up;

A: Adjustment;

C: Cleaning;

R: Replacement;

T: Tightening;

M: Maintenance;

D: Diagnosis

Maintenance and diagnosis

check-up must be performed

based on standard procedures

of national dealer shops.

When finding necessities for

cleaning, replenishing

lubricants, part adjustment or

replacement where pollutant

emission is not yet severe

during riding or checking-up,

carry out necessary actions

accordingly and make records

of them. If the pollutant

emission is severe, report the

anomaly for approval before

carrying out maintenance.

It is suggested that 1 bottle of

KYMCO specified Fuel

Injection Nozzle Cleaner must

be added in the Fuel Tank every

1000km.

Fuel Injection Nozzle and

Throttle Valve Body must be

cleaned every 3 months or

before reaching 10000km.

Oil filter

C

C

C

C

C

Gear Oil

Fuel Supply

System

Fuel pump/Fuel pump filter

I/C

I/C

I/C

I/C

Throttle Cable

I

I

I

I

Air Supply

System

Air Cleaner Element

C

R

C

R

C

R

Active Carbon Canister

I

I

I

I

Filter wool in Transmission System

(none for this model)

PCV Evaporation control valve

I

I

I

I

Control of relevant air duct

I

I

I

I

Catalytic Converter

I

I

I

I

Transmission

System

Cam Chain

I

I

I

I

Transmission Chain

I

I

I

I

Drive Belt (none for this model)

M

M

I

Valve Gap

I

I

I

Ignition

System

Spark Plug

4-stroke

I

R

I

I

Ignition circuitry

I

I

I

I

Engine

Management

System

Throttle Valve (Body)

M/I

M/I

M/I

Fuel Injection Nozzle

D/M

D/M

D/M

C

D/M

D/M

Idle Air Bypass Valve

D/M

D/M

D/M

Engine Temperature Sensor

D

D

D

D

D

D

Air Intake Pressure Sensor

D

D

D

D

D

D

Reverse Sensor

D

D

D

D

D

D

Ignition Coil

D

D

D

D

D

D

Battery

D

D

D

D

D

D

Other

Major Chassis Bolts

T

T

T

T

T

T

T

T

T

T

T

T

T

T

T

T

Brake System (Disc Brake System)

I

I

I

I

I

I

I

I

I

I

M

I

I

I

I

I

Brake Cable

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

Non-schedule Maintenance

Item

Symptom and Remedy

Ignition System

Maintenance or inspection must be carried out if significant and continued ignition anomalies occur, engine overheats, or engine stops.

Eliminate Carbon Accumulation

If engine power output drops significantly between 10000-15000 km mileage, maintenance or inspection must be carried out for the system; replace it if necessary.

Transmission System

In the event of significant dropping of extreme speed around mileage of 5000 km, perform maintenance and inspection of the system; replace the system if necessary.

Piston

If excessive use occurs within the first 1000km, wear or seizure of piston, piston ring of cylinder may occur. Clean or re-bore the cylinder or replace piston with a new one.

Fuel Injection Nozzle

Clear out carbon accumulation or adhesion from Fuel Injection Nozzle every 1000km or when the vehicle is left unused for a long time.

Summary of Contents for RT30HE

Page 1: ...SPADE 150 Fi Series Scooter Owner s Manual ...

Page 6: ...1 1 Precautions on Safe Driving 1 1 Checks before driving 1 5 Clothing 1 6 Loading ...

Page 13: ......

Page 14: ......

Page 15: ......

Page 16: ...2 2 Motorcycle Parts 2 1 Right View 2 2 Left View ...

Page 19: ......

Page 27: ...3 7 3 ...

Page 28: ...4 4 Starting the Engine 4 1 Electrical Start 4 2 Handling a Tumbled Vehicle ...

Page 31: ......

Page 39: ......

Page 40: ...6 6 Checks before Riding 6 1 Checks before Riding 6 12 Periodical Checks ...

Page 70: ...9 9 Specifications 9 1 SPADE 150Fi Specifications RT30HE ...

Page 72: ......

Page 74: ......