2H4

2-1-10

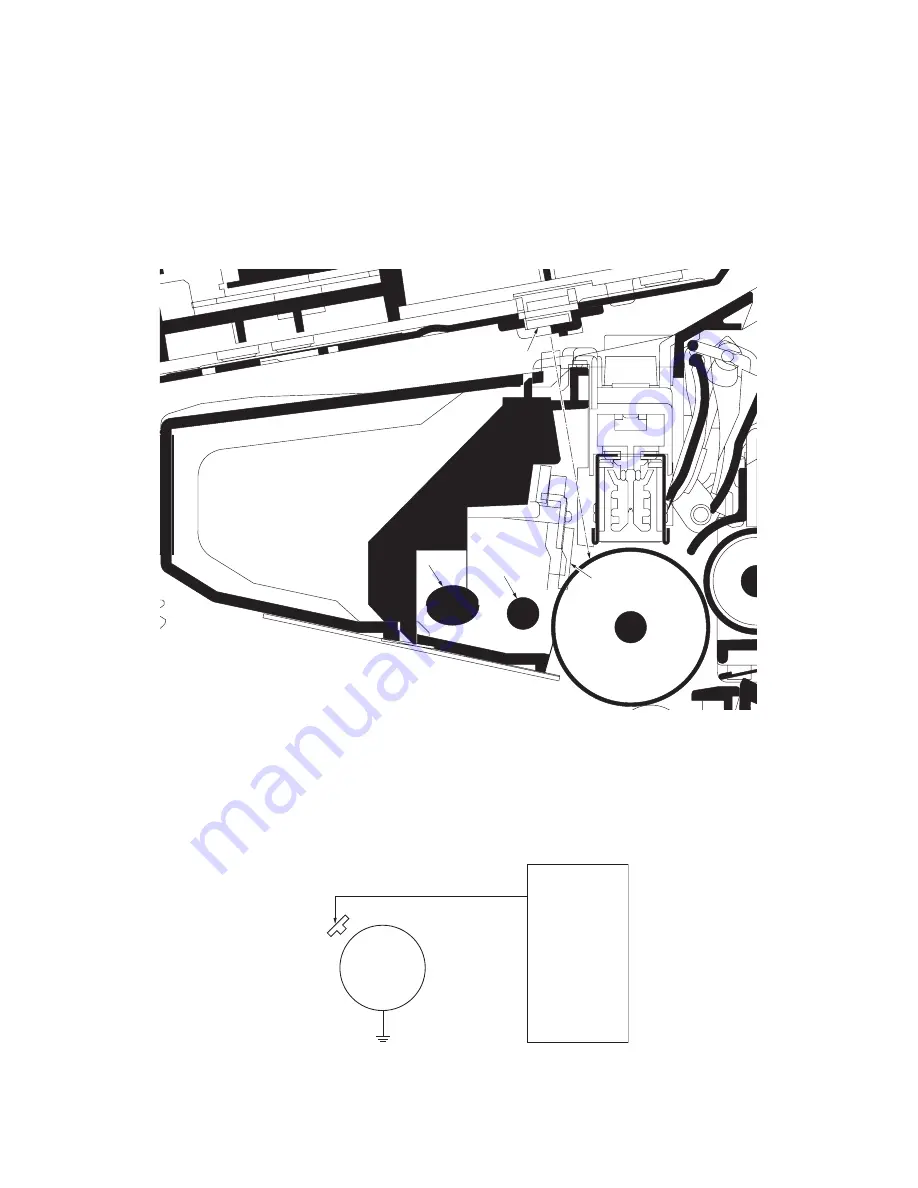

2-1-6 Cleaning section

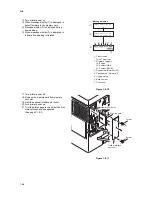

After the transferring process, the drum needs to be physically cleaned of toner which is residual after the development

process. The cleaning blade is constantly pressed against the drum and scrapes the residual toner off to the sweep roller.

The waste toner is collected at the output end of the sweep roller and sent back to the toner container, into the waste toner

reservoir.

After the drum is physically cleaned, it then must be cleaned to the electrically neutral state. This is necessary to erase any

residual positive charge, ready to accept the uniform charge for the next print process. The residual charge is canceled by

exposing the drum to the light emitted from the eraser lamp (PWB). This lowers the electrical conductivity of the drum sur-

face making the residual charge on the drum surface escape to the ground.

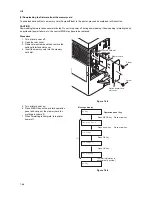

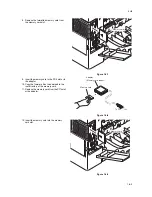

Figure 2-1-16 Cleaning section

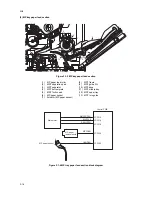

Figure 2-1-17 Cleaning section block diagram

1

2

4

3

Main frame

Waste toner reservoir

Drum unit

(1)

Eraser lamp (PWB)

(2)

Sweep roller

(3)

Toner conveying roller

(4)

Cleaning blade

ERASER

Drum

Eraser

lamp

(PWB)

Control PWB

YC342-1

Summary of Contents for ECOSYS FS-1350DN

Page 1: ...SERVICE MANUAL Published in October 2008 842H4010 2H4SM060 First Edition FS 1350DN ...

Page 3: ...Revision history Revision Date Replaced pages Remarks ...

Page 4: ...This page is intentionally left blank ...

Page 10: ...This page is intentionally left blank ...

Page 18: ...2H4 1 1 6 This page is intentionally left blank ...

Page 21: ...2H4 1 2 3 1 Removing the tapes Procedure 1 Remove three tapes Figure 1 2 3 Tape Tape Tape ...

Page 24: ...2H4 1 2 6 This page is intentionally left blank ...

Page 57: ...2H4 1 5 5 5 Unhook seven hooks and then remove the left cover Figure 1 5 6 Left cover Hooks ...

Page 106: ...2H4 2 1 16 This page is intentionally left blank ...

Page 110: ...2H4 2 2 4 This page is intentionally left blank ...

Page 118: ...2H4 2 3 8 This page is intentionally left blank ...

Page 121: ......

Page 122: ......