2M2/2M3

1-2-3

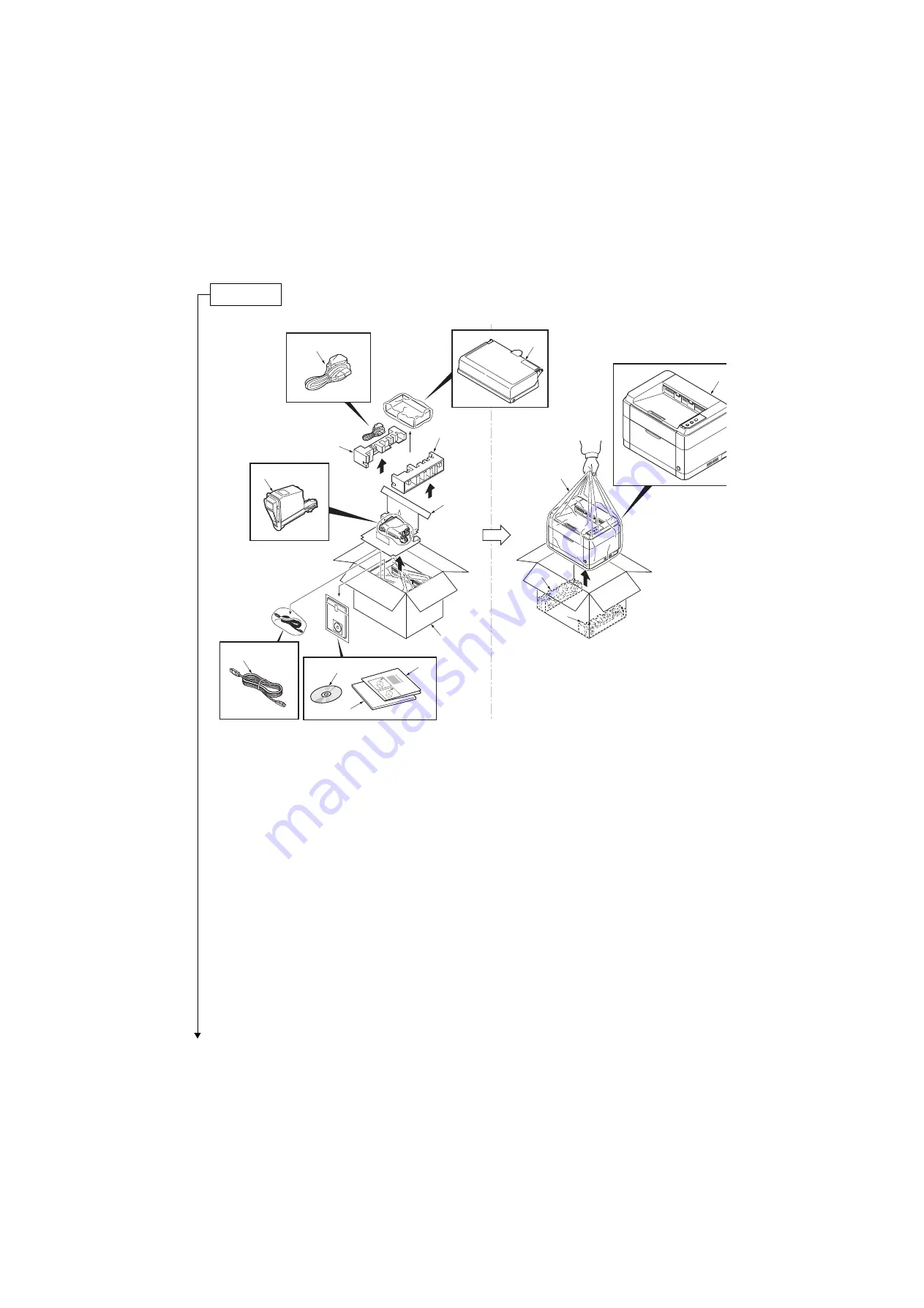

Figure 1-2-3

*: Place the machine on a level surface.

Unpacking

4

2

1

6

8

3

5

9

12

10

11

13

14

7

15

1. Machine

2. Outer case

3. Bottom left pad

4. Bottom right pad

5. Machine cover

6. Top left pad

7. Top right pad

8. Top spacer

9. Cassette cover

10. Power cord

11. Toner container

12. DVD

13. Operation guide

14. Quick installation guide

15. USB cable*1

*1:Chaina model only

Summary of Contents for FS-1040

Page 1: ...SERVICE MANUAL Published in March 2012 842M3110 2M3SM060 First Edition FS 1040 FS 1060DN ...

Page 3: ...Revision history Revision Date Replaced pages Remarks ...

Page 4: ...This page is intentionally left blank ...

Page 10: ...This page is intentionally left blank ...

Page 14: ...2M2 2M3 This page is intentionally left blank ...

Page 66: ...2M2 2M3 1 4 20 This page is intentionally left blank ...

Page 100: ...2M2 2M3 2 1 14 This page is intentionally left blank ...

Page 130: ......

Page 131: ...2012 ...