36

Using the Printer

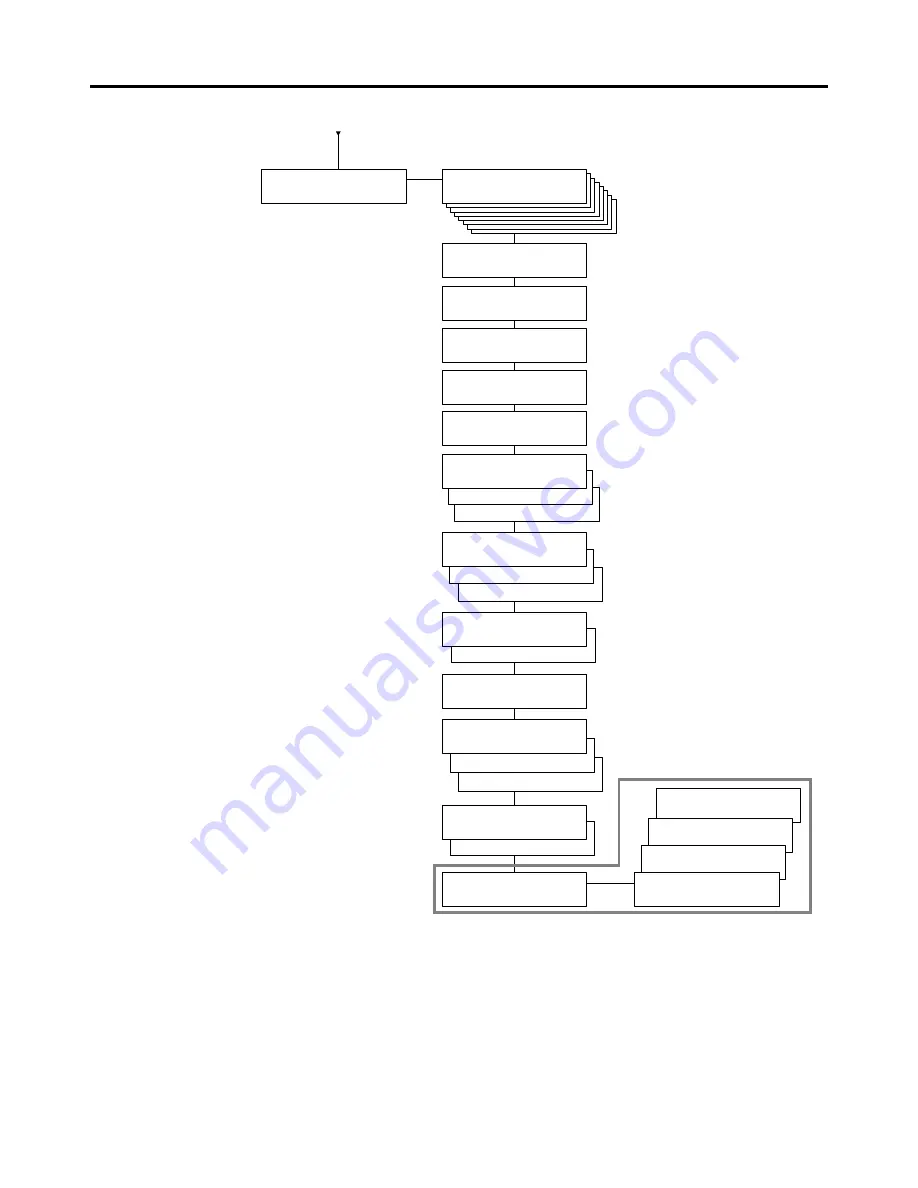

Ignore LF

CR and LF

>LF action

LF only

>Printer Reset

Continued from previous page

Ignore CR

CR and LF

>CR action

CR only

>MSG language

English

>List of

>Print HEX-DUMP

>Sleep timer

060 min

>Form Feed

Time out 030sec.

resident Fonts

Others >

On

Perm / Temp

On

Permanent

>>Print

Test page 2

>>Print

Test Page 1

>Buzzer

Off

>Service

>

>Ecoprint mode

>Resolution

Off

>Resource prot.

Off

(

*6)

(

*5)

(

*7)

>>TransferRoller

? Type X

Status Page

*2

: The printer can be set to print error data during KPDL

emulation. If this is set to

On

, error data will be printed

if trouble occurs during printing. This is set to

Off

before leaving the factory.

*3

: The

>Size

menu is not available for the

Courier

and

LetterGothic

fonts. Use the

>Pitch

menu to scale

these fixed fonts.

*4

: The

RAM DISK mode

menu is not displayed when an

optional hard disk unit is installed.

*5

: Any value from 0 to 495 [seconds] in 5-second

increments. (The printer does not time out with the

value set to 0.)

*6

: Any value from 0 to 120 [minutes] in 5-minute

increments.

*7

: For service purpose only.