When a bypass diode is wired in parallel with the series string, the forced current will flow through the diode and bypass

the shaded module, thereby minimizing module heating and array current losses.

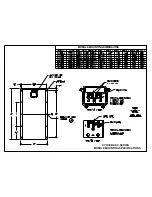

For 12-volt systems and higher: Each module junction box has a diagram illustrating the proper orientation of the

bypass diode installed between two of the terminal screws (Figure 11, Figure 12). When the solar modules are

connected as individual series strings first, and then these strings are connected in parallel, bypass diodes should be

used in each junction box. This is the simplest wiring arrangement for most installations.

Diodes that are used as bypass diodes must:

・

Have a Rated Average Forward Current [I

F(AV)

]

Above

maximum system current at highest module operating

temperature.

・

Have a Rated Repetitive Peak Reverse Voltage [V

RRM

]

Above

maximum system voltage at lowest module

operating temperature.

12. MAINTENANCE

Kyocera modules are designed for long life and require very little maintenance. Under most weather conditions, normal

rainfall is sufficient to keep the module glass surface clean. If dirt build-up becomes excessive, clean the glass surface

only with a soft cloth using mild detergent and water. USE CAUTION WHEN CLEANING THE BACK SURFACE OF

THE MODULE TO AVOID PENETRATING THE PVF SHEET. Modules that are mounted flat (0

°

tilt angle) should be

cleaned more often, as they will not "self clean" as effectively as modules mounted at a 15

°

tilt or greater. Once a

year, check the tightness of terminal screws and the general condition of the wiring. Also, check to be sure that

mounting hardware is tight. Loose connections will result in a damaged module or array.

13. SPECIFICATIONS

The electrical and physical specifications can be found at the end of this document (Table 2).

NOTES

・

The electrical characteristics are within

±

10 percent of indicated values of Isc, Voc, and Pmax under standard test

conditions (irradiance of 1KW/m

2

, AM 1.5 spectrum, and cell temperature of 25

℃

).

・

Under certain conditions, a photovoltaic module is likely to produce more current and / or voltage than reported at

standard test conditions. Accordingly, the values of Isc and Voc marked on this module should be multiplied by a

factor of 1.25 when determining component voltage ratings, conductor ampacities, fuse sizes, and sizes of

regulators which are connected to the PV output. Refer to Section 690-8 of the National Electrical Code for an

additional multiplying factor of 125 (80 per cent derating) which may also be applicable.

MANUFACTURED IN JAPAN BY KYOCERA CORPORATION

KSI GROUP

Kyocera Solar Inc. (Headquarters)

7812 East Acoma Drive, Scottsdale, AZ 85260, USA

Tel: (480) 948-8003 or (800) 223-9580

Fax: (480) 483-6431

www.kyocerasolar.com

Kyocera Solar Pty, Ltd.

36 Windorah St., Unit 6 Stafford 4053 Queensland, Australia

Tel: (61) 7-3856-5388

Fax: (61) 7-3856-5443

Kyocera Solar Argentina S.A.

Mejico 2145, 16400 Martinez Prov. de Buenos Aires Argentina

Tel: (54) 114-836-1040

Fax: (54) 114-836-0808

Kyocera Solar Do Brazil

Rua Mauricio da Costa Faria, 85

22780-280

–

Recreio

–

Rio de Janeiro

Tel: (55) 2-1554-5554

Fax: (55) 2-1553-4894

KFG GROUP

Kyocera Fineceramics GmBH

Fritz M

ü

ller Strasse 107, D-73730 Esslingen, Germany

Phone: (49) 711-9393-417

Fax: (49) 711-9393-450

www.kyocera.de/products/solar.htm

KAP GROUP

Kyocera Asia Pacific Singapore

Fritz M

ü

ller Strasse 107, D-73730 Esslingen, Germany

298 Tiong Bahru Road, #13-03/05 Tiong Bahru Plaza Singapore

168730

Tel: (65) 271-0500

Fax: (65) 271-0600