2JZ/2JX/2JV/2H7-1

1-4-44

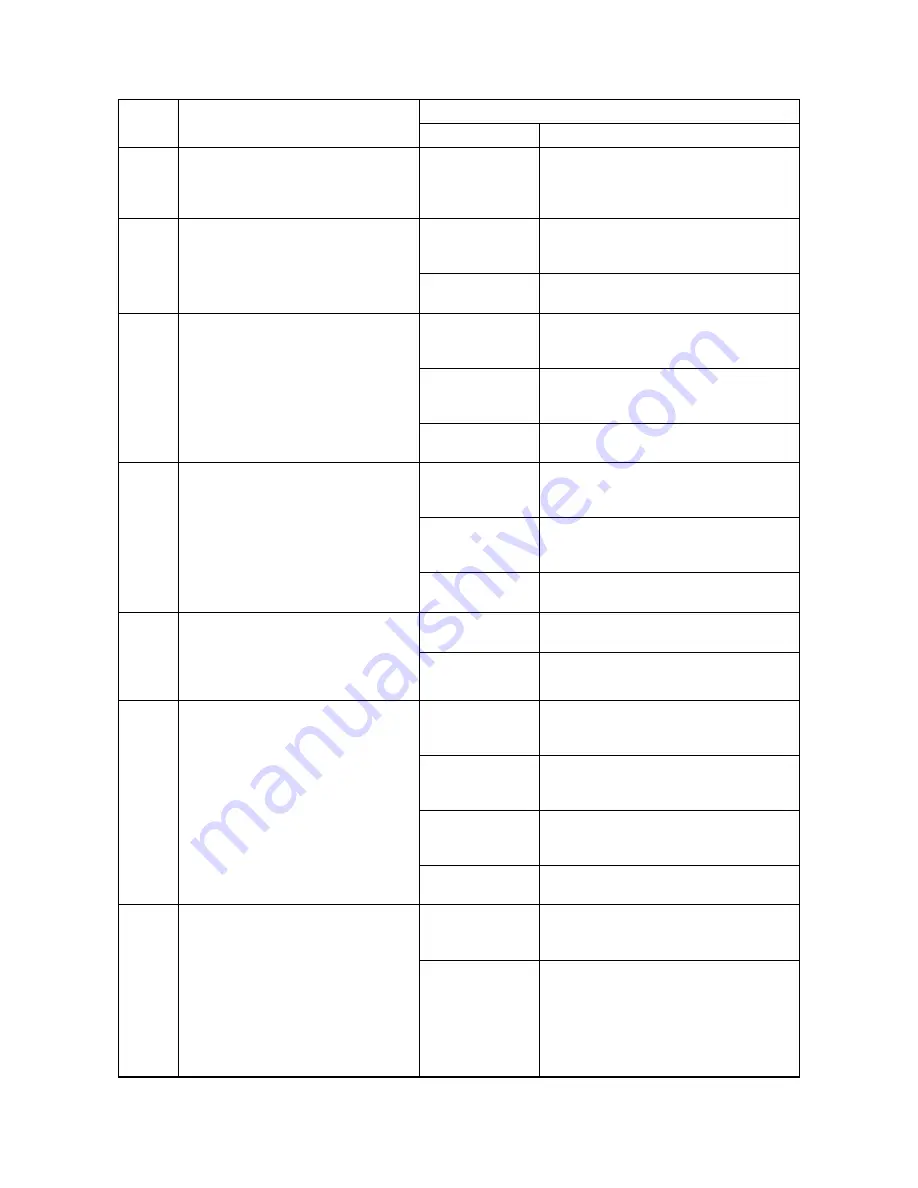

C6010

Abnormally high fuser thermistor

temperature

The fuser Abnormally high signal is

detected for 60 s or more.

Defective PWB.

Replace the power source PWB or engine

PWB and check for correct operation.

C6020

Abnormally high fuser thermistor 1

temperature

The fuser temperature exceeds 240

C/

464

F for 1 s.

Installation defec-

tiveness on fuser

thermistor 1.

Measure the resistance. If it is

, replace

the fuser unit (see page 1-5-41).

Defective PWB.

Replace the power source PWB or engine

PWB and check for correct operation.

C6030

Fuser thermistor 1 break error

During warming up, fuser thermistor 1

does not detect temperature rise of 1

C/

1.8

F for 10 s.

When the difference of temperature of

fuser thermistor 1 and 2 becomes 100

C/212

F or more.

Defective fuser

heater 1.

Check for continuity across each heater. If

none, replace the fuser unit (see page 1-5-

41).

Installation defec-

tiveness on fuser

thermistor 1.

Measure the resistance. If it is

, replace

the fuser unit (see page 1-5-41).

Defective PWB.

Replace the power source PWB or engine

PWB and check for correct operation.

C6040

Fuser heater error

Fuser thermistor 1 detects temperature

change of 20

C/36

F or more for 160

ms 100 times or more since the power is

turned on.

Defective fuser

heater 1.

Check for continuity across each heater. If

none, replace the fuser unit (see page 1-5-

41).

Installation defec-

tiveness on fuser

thermistor 1.

Measure the resistance. If it is

, replace

the fuser unit (see page 1-5-41).

Defective PWB.

Replace the power source PWB or engine

PWB and check for correct operation.

C6050

Abnormally low fuser thermistor 1

temperature

During printing, the temperature at the

heat roller lower than 100

C/212

F is

detected continuously for 1 s.

Defective fuser

heater 1.

Replace the fuser unit (see page 1-5-41).

Defective PWB.

Replace the power source PWB or engine

PWB and check for correct operation.

C6100

Fuser heater 2 break

Fuser thermistor 2 detected less than

100

C/212

F for 120 s during driving.

Fuser thermistor 2 deduced less than

150

C/302

F for 300 s during driving.

Fuser thermistor 2 deduced less than

100

C/212

F for 5 s during driving.

Defective fuser

heater 2.

Check for continuity across each heater. If

none, replace the fuser unit (see page 1-5-

41).

Defective fuser

thermostat 2.

Check for continuity across thermostat. If

none, remove the cause and replace the

fuser unit (see page 1-5-41).

Installation defec-

tiveness on fuser

thermistor 2.

Measure the resistance. If it is

, replace

the fuser unit (see page 1-5-41).

Defective PWB.

Replace the power source PWB or engine

PWB and check for correct operation.

C6120

Abnormally high fuser thermistor 2

temperature

The fuser temperature exceeds 190

C/

374

F for 1 s.

Installation defec-

tiveness on fuser

thermistor 2.

Measure the resistance. If it is

, replace

the fuser unit (see page 1-5-41).

Defective PWB.

Replace the power source PWB or engine

PWB and check for correct operation.

Code

Contents

Remarks

Causes

Check procedures/corrective measures

Summary of Contents for TASKalfa 250ci

Page 4: ...This page is intentionally left blank ...

Page 10: ...This page is intentionally left blank ...

Page 14: ...2JZ 2JX 2JV 2H7 This page is intentionally left blank ...

Page 296: ...2JZ 2JX 2JV 2H7 1 4 78 This page is intentionally left blank ...

Page 348: ...2JZ 2JX 2JV 2H7 1 5 52 This page is intentionally left blank ...

Page 354: ...2JZ 2JX 2JV 2H7 1 6 6 This page is intentionally left blank ...

Page 378: ...2JZ 2JX 2JV 2H7 2 1 24 This page is intentionally left blank ...

Page 388: ...2JZ 2JX 2JV 2H7 2 2 10 This page is intentionally left blank ...

Page 390: ...2JZ 2JX 2JV 2H7 1 2 3 2 Power source PWB ...

Page 395: ...2JZ 2JX 2JV 2H7 1 2 3 7 Engine PWB ...

Page 412: ...2JZ 2JX 2JV 2H7 1 2 3 24 Main PWB ...

Page 430: ...2JZ 2JX 2JV 2H7 1 2 3 42 Feed PWB 40 40 50 40 ppm model Feed PWB 25 25 30 30 ppm model ...

Page 450: ...2JZ 2JX 2JV 2H7 2 4 8 ...

Page 493: ...INSTALLATION GUIDE FOR PAPER FEEDER ...

Page 503: ...INSTALLATION GUIDE FOR 3000 SHEETS PAPER FEEDER ...

Page 558: ...INSTALLATION GUIDE FOR CENTER FOLDING UNIT ...

Page 572: ...INSTALLATION GUIDE FOR MAILBOX ...

Page 580: ...INSTALLATION GUIDE FOR HOLE PUNCH UNIT ...

Page 592: ...INSTALLATION GUIDE FOR JOB SEPARATOR ...

Page 602: ...INSTALLATION GUIDE FOR FAX System ...

Page 619: ...INSTALLATION GUIDE FOR DT 710 ...

Page 622: ...INSTALLATION GUIDE FOR DUCT UNIT ...

Page 625: ......

Page 626: ......