2JZ/2JX/2JV/2H7-5

1-3-11

U000

Maintenance

item No.

Description

No.

Items

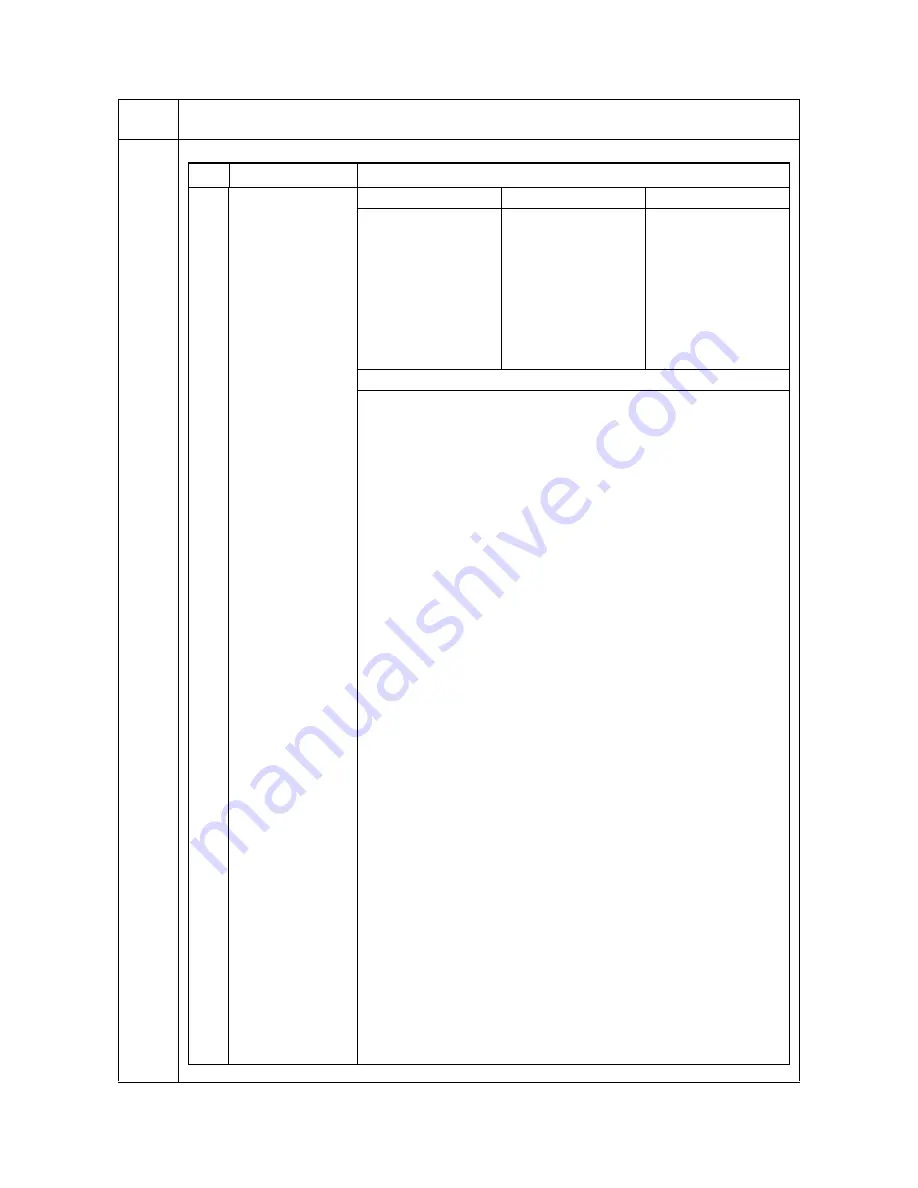

Description

(8)

Paper Jam Log

#

Count.

Event

Remembers 1 to 16 of

occurrence. If the

occurrence of the previ-

ous paper jam is less

than 16, all of the paper

jams are logged. When

the occurrence

excesseds 16, the old-

est occurrence is

removed.

The total page count at

the time of the paper

jam.

Log code (2 digit, hexa-

decimal, 5 categories)

(a) Cause of a paper

jam

(b) Paper source

(c) Paper size

(d) Paper type

(e) Paper eject

(a) Cause of paper jam (Hexadecimal)

00: Initial JAM

04: Cover open JAM

05: Secondary paper feed does not start

09: Sequence error JAM

10: No paper feed from cassette 1

11: No paper feed from cassette 2

12: No paper feed from optional cassette 3

13: No paper feed from optional cassette 4

14: No paper feed from MP tray

15: Misfeed in paper feeder horizontal paper conveying section 1

16: Misfeed in paper feeder horizontal paper conveying section 2

17: Misfeed in paper feeder horizontal paper conveying section 3

18: Misfeed in vertical paper conveying section

19: Misfeed in paper feeder paper conveying section

21: Multiple sheets in MP tray paper feed section

22: Multiple sheets in cassette 1 paper feed section

23: Multiple sheets in cassette 2 paper feed section

24: Multiple sheets in cassette 3 paper feed section

25: Multiple sheets in cassette 4 paper feed section

26: Multiple sheets in MP tray paper feed section

30: Misfeed in registration/transfer section

31: Misfeed round the transfer belt

40: Misfeed in fuser section (MP tray)

41: Misfeed in fuser section (cassette 1)

42: Misfeed in fuser section (cassette 2)

43: Misfeed in fuser section (cassette 3)

44: Misfeed in fuser section (cassette 4)

45: Misfeed in fuser section (3000-sheet paper feeder)

46: Misfeed in fuser section (duplex section)

50: Misfeed in eject section

51: Misfeed in job separator eject section

52: Misfeed in feedshift section

60: Misfeed in duplex paper conveying section 1

61: Misfeed in duplex paper conveying section 2

70: No original feed

71: An original jam in the original feed section

72: An original jam in the original conveying section

73: An original jam in the original registration section

74: An original jam in the original feed section

75: An original jam in the original conveying section

76: An original jam in the original switchback section 1

77: An original jam in the original switchback section 2

Summary of Contents for TASKalfa 250ci

Page 4: ...This page is intentionally left blank ...

Page 10: ...This page is intentionally left blank ...

Page 14: ...2JZ 2JX 2JV 2H7 This page is intentionally left blank ...

Page 296: ...2JZ 2JX 2JV 2H7 1 4 78 This page is intentionally left blank ...

Page 348: ...2JZ 2JX 2JV 2H7 1 5 52 This page is intentionally left blank ...

Page 354: ...2JZ 2JX 2JV 2H7 1 6 6 This page is intentionally left blank ...

Page 378: ...2JZ 2JX 2JV 2H7 2 1 24 This page is intentionally left blank ...

Page 388: ...2JZ 2JX 2JV 2H7 2 2 10 This page is intentionally left blank ...

Page 390: ...2JZ 2JX 2JV 2H7 1 2 3 2 Power source PWB ...

Page 395: ...2JZ 2JX 2JV 2H7 1 2 3 7 Engine PWB ...

Page 412: ...2JZ 2JX 2JV 2H7 1 2 3 24 Main PWB ...

Page 430: ...2JZ 2JX 2JV 2H7 1 2 3 42 Feed PWB 40 40 50 40 ppm model Feed PWB 25 25 30 30 ppm model ...

Page 450: ...2JZ 2JX 2JV 2H7 2 4 8 ...

Page 493: ...INSTALLATION GUIDE FOR PAPER FEEDER ...

Page 503: ...INSTALLATION GUIDE FOR 3000 SHEETS PAPER FEEDER ...

Page 558: ...INSTALLATION GUIDE FOR CENTER FOLDING UNIT ...

Page 572: ...INSTALLATION GUIDE FOR MAILBOX ...

Page 580: ...INSTALLATION GUIDE FOR HOLE PUNCH UNIT ...

Page 592: ...INSTALLATION GUIDE FOR JOB SEPARATOR ...

Page 602: ...INSTALLATION GUIDE FOR FAX System ...

Page 619: ...INSTALLATION GUIDE FOR DT 710 ...

Page 622: ...INSTALLATION GUIDE FOR DUCT UNIT ...

Page 625: ......

Page 626: ......