2JZ/2JX/2JV/2H7-5

1-3-52

U091

Setting the white line correction

Description

Sets the error detection threshold value for white line correction and displays the count result of abnormal pixels.

Purpose

To perform when replacing the CIS, DP driver PWB or CIS roller.

Method: white line correction

1. Press the start key.

2. Press [EXECUTE].

3. Press the start key. Holding of white reference data is started.

4. The count result of abnormal pixels is displayed.

5. Press the system menu key.

6. Place a gray original on the DP with the gray side down. Load paper in the cassette.

The paper should be the same size as the original.

7. Press the start key.

Two test pattern sheets will be printed. (1st sheet: blank sheet, 2nd sheet: Approx. 60 mm black band)

8. If no vertical lines appear on either sheet, the setting has been completed normally.

If vertical black lines appear on the blank sheet and vertical white lines appear in the black band in the

same position, clean the CIS roller and the CIS glass and then repeat white line correction.

If vertical black lines or vertical white lines appear on both sheets, white line correction has been com-

pleted normally. However, the cause of the vertical lines lies in the engine, and thus the engine must be

checked.

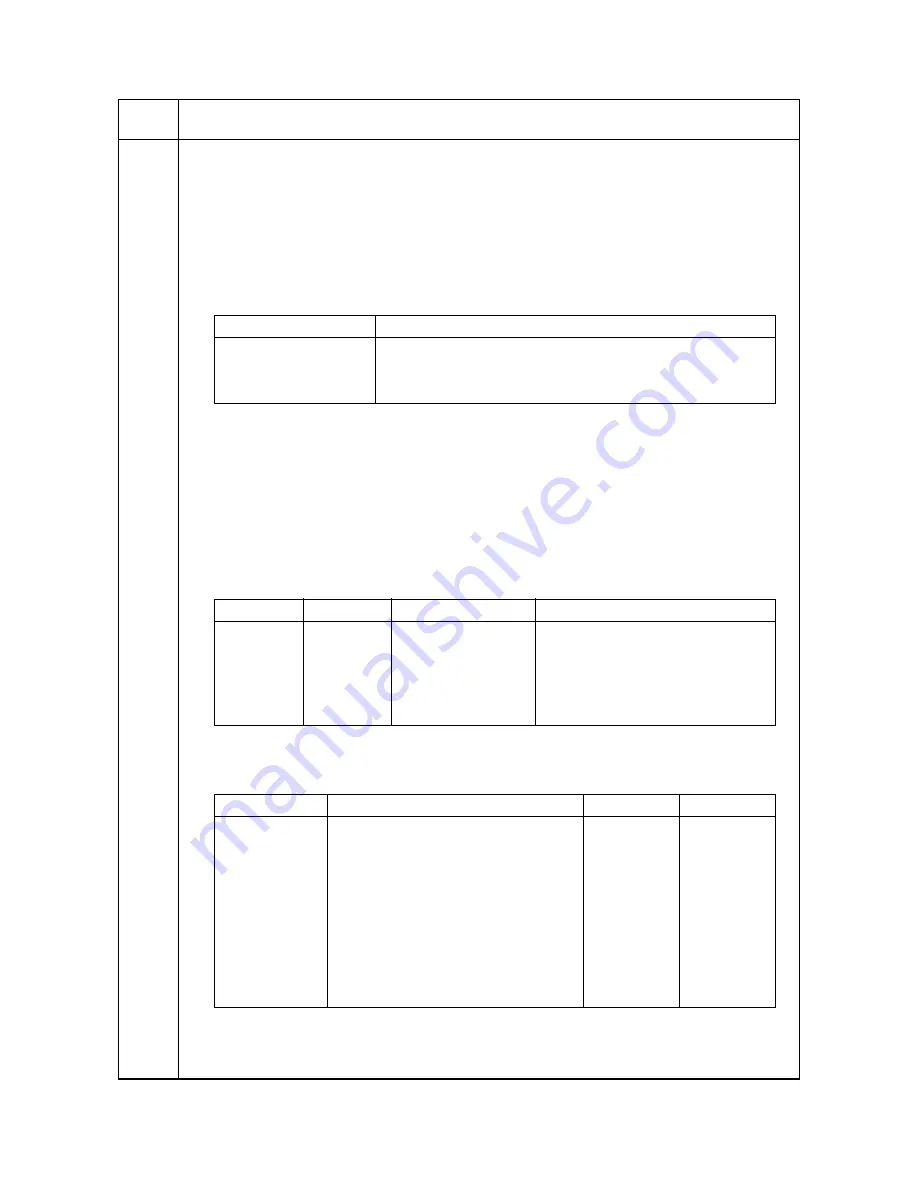

How to view test copies

Setting: Threshold value setting

1. Select the item to be set.

2. Change the value using the +/- or numeric keys.

*: Normally the Threshold (Com) value should not be changed from 112, the initial setting.

If white lines appear even though the CIS roller and glass are not dirty, raise the set value.

If fine lines in some originals disappear, lower the set value.

Set within the range 50 to 200. (If set outside this range, the image may be affected.)

Maintenance

item No.

Description

Display

Description

Calculation(R)

Abnormal pixel count result for color R

Calculation(G)

Abnormal pixel count result for color G

Calculation(B)

Abnormal pixel count result for color B

blank sheet

black band

Causes

Corrective measures

No lines

No lines

-

Complete

Black lines

White lines

Dirty CIS roller or CIS

glass

Clean CIS roller or CIS glass and then

perform U091 again

Black lines

No lines

Engine side

U091 ends, check engine

No lines

White lines

Engine side

U091 ends, check engine

Display

Description

Setting range

Initial setting

Threshold(R)

Displaying of abnormal pixel detection

threshold value for color R

-

-

Threshold(G)

Displaying of abnormal pixel detection

threshold value for color G

-

-

Threshold(Com)*

Setting of abnormal pixel detection thresh-

old value for color

0 to 1023

112

Abnorm Pixel

Threshold

Abnormal pixel threshold value setting

0 to 8191

75

MODE

Switching between white line correction

mode ON/OFF

0: OFF/1: ON/

2: Test mode

0

Summary of Contents for TASKalfa 250ci

Page 4: ...This page is intentionally left blank ...

Page 10: ...This page is intentionally left blank ...

Page 14: ...2JZ 2JX 2JV 2H7 This page is intentionally left blank ...

Page 296: ...2JZ 2JX 2JV 2H7 1 4 78 This page is intentionally left blank ...

Page 348: ...2JZ 2JX 2JV 2H7 1 5 52 This page is intentionally left blank ...

Page 354: ...2JZ 2JX 2JV 2H7 1 6 6 This page is intentionally left blank ...

Page 378: ...2JZ 2JX 2JV 2H7 2 1 24 This page is intentionally left blank ...

Page 388: ...2JZ 2JX 2JV 2H7 2 2 10 This page is intentionally left blank ...

Page 390: ...2JZ 2JX 2JV 2H7 1 2 3 2 Power source PWB ...

Page 395: ...2JZ 2JX 2JV 2H7 1 2 3 7 Engine PWB ...

Page 412: ...2JZ 2JX 2JV 2H7 1 2 3 24 Main PWB ...

Page 430: ...2JZ 2JX 2JV 2H7 1 2 3 42 Feed PWB 40 40 50 40 ppm model Feed PWB 25 25 30 30 ppm model ...

Page 450: ...2JZ 2JX 2JV 2H7 2 4 8 ...

Page 493: ...INSTALLATION GUIDE FOR PAPER FEEDER ...

Page 503: ...INSTALLATION GUIDE FOR 3000 SHEETS PAPER FEEDER ...

Page 558: ...INSTALLATION GUIDE FOR CENTER FOLDING UNIT ...

Page 572: ...INSTALLATION GUIDE FOR MAILBOX ...

Page 580: ...INSTALLATION GUIDE FOR HOLE PUNCH UNIT ...

Page 592: ...INSTALLATION GUIDE FOR JOB SEPARATOR ...

Page 602: ...INSTALLATION GUIDE FOR FAX System ...

Page 619: ...INSTALLATION GUIDE FOR DT 710 ...

Page 622: ...INSTALLATION GUIDE FOR DUCT UNIT ...

Page 625: ......

Page 626: ......