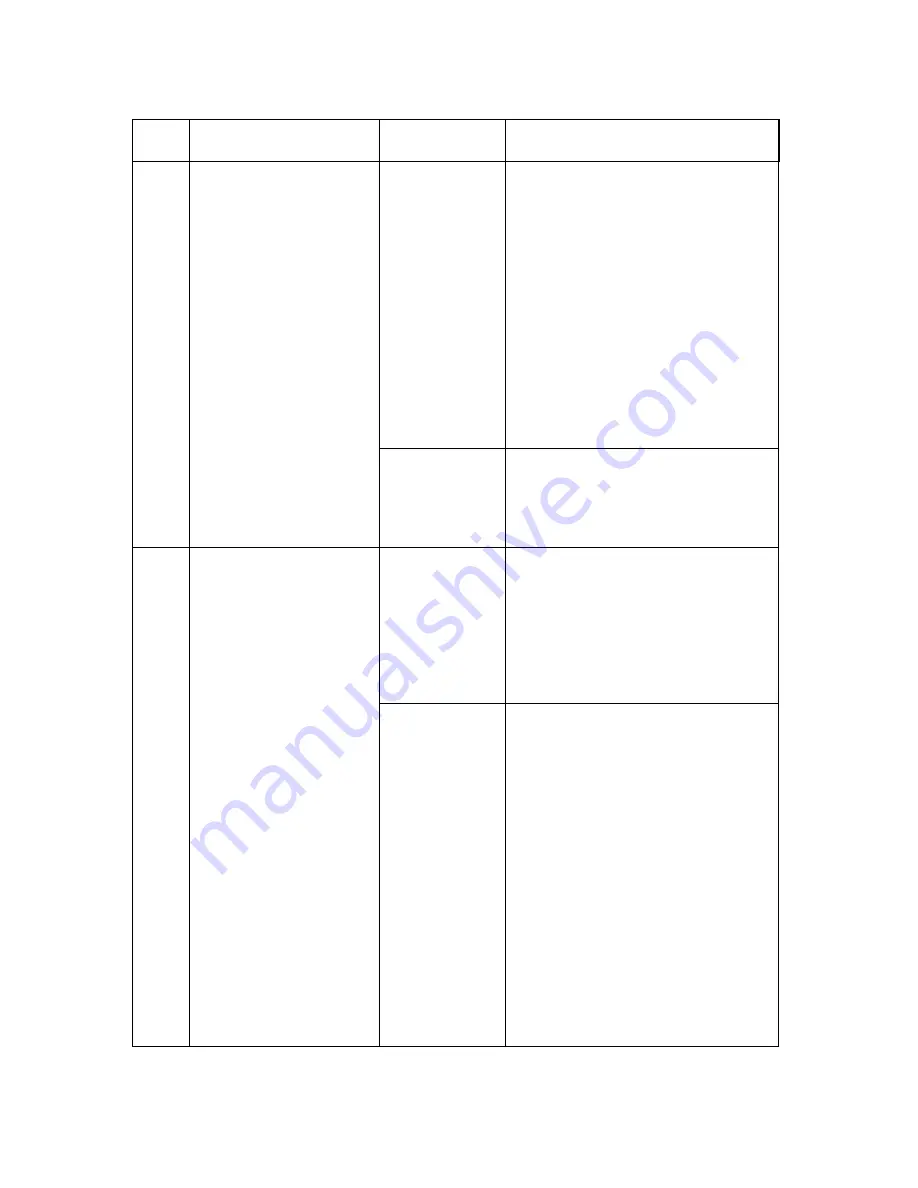

2L6/2N6/2N5/2N4

1-4-103

2860

Intermediate transfer belt

sub sensor error

The signal is not received for

100 ms in succession.

Transfer belt

sensor

1. To check the motor operation, execute

U030 Belt Meand (see page 1-3-34).

2. Check that the drive roller for the sensor

pulse can be rotated.

3. Check that the sensor is correctly

positioned.

4. Confirm that the wiring connector is

firmly connected and, if necessary,

connect the connector all the way in.

Transfer belt sensor and intermediate

transfer belt unit and Engine PWB (YC3)

5. If the wiring is disconnected, shorted or

grounded, replace the wiring.

6. Replace the intermediate transfer belt

unit.

Engine PWB

1. Check the engine software and upgrade

to the latest, if necessary.

2. Replace the engine PWB (see page 1-5-

80).

2950

Motor control PWB commu-

nication error

A communication error from

the motor control PWB is

detected 10 times in succes-

sion.

Motor control PWB

1. Confirm that the wiring connector is

firmly connected and, if necessary,

connect the connector all the way in.

Motor control PWB (YC3) and Engine

PWB (YC9)

2. If the wiring is disconnected, shorted or

grounded, replace the wiring.

3. Replace the Motor control PWB.

Engine PWB

1. Check the engine software and upgrade

to the latest, if necessary.

2. Replace the engine PWB (see page 1-5-

80).

Code

Contents

Related parts

Check procedures/

corrective measures

Summary of Contents for TASKalfa 3051ci

Page 5: ...2L6 2N6 2N5 2N4 1 4 4 Machine Option2 Figure 1 4 4 Paper jam location Matchine Option2 ...

Page 201: ...2L6 2N6 2N5 2N4 5 1 4 200 ...

Page 202: ...2L6 2N6 2N5 2N4 5 1 4 201 ...

Page 203: ...2L6 2N6 2N5 2N4 5 1 4 202 ...

Page 204: ...2L6 2N6 2N5 2N4 5 1 4 203 ...

Page 257: ...2L6 2N6 2N5 2N4 5 1 4 256 16 Grainy image See page1 4 272 ...