2L6/2N6/2N5/2N4

1-4-223

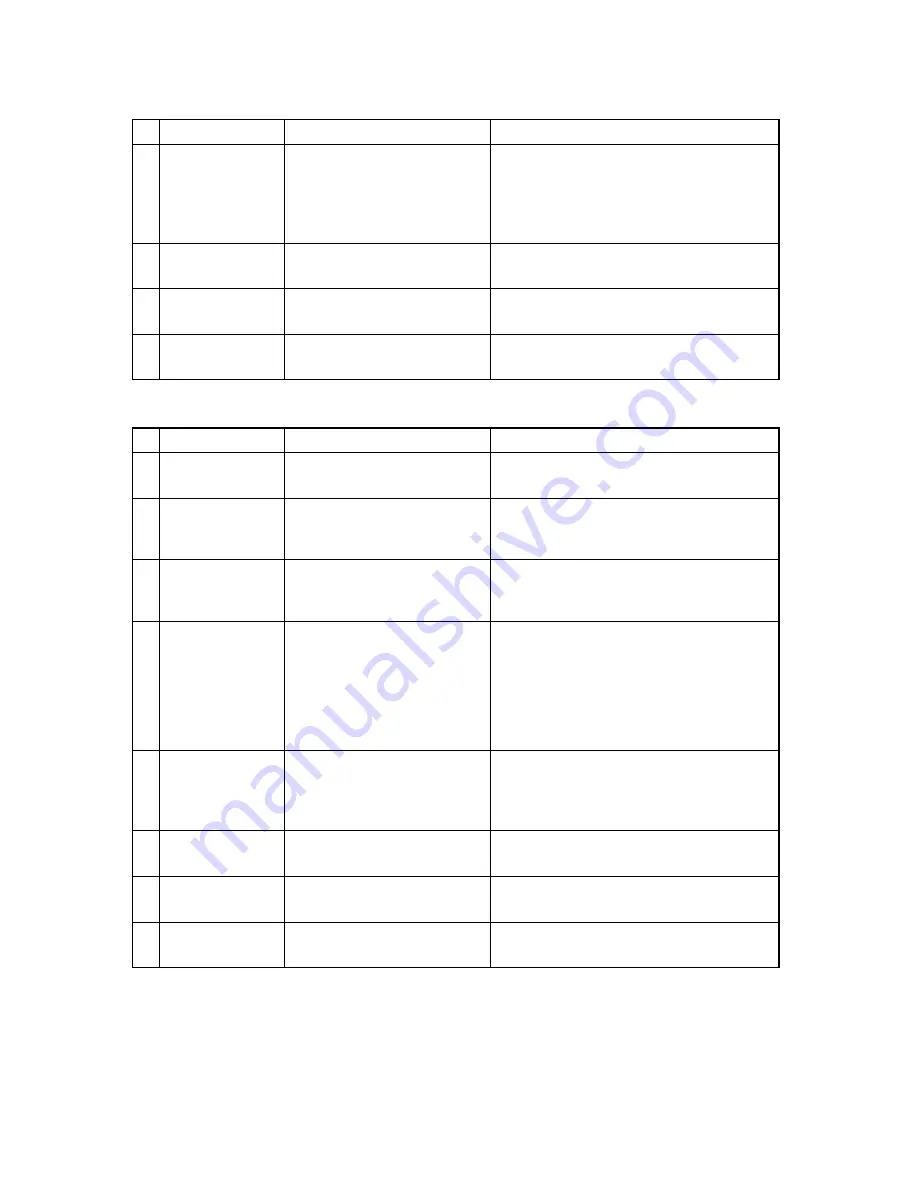

2. DP-scanning first (front) page

9

Shading plate

Check whether the shading plate

is dirty.

If the shading plate is dirty, perform

maintenance mode U063 to modify the

shading position. If it does not cure, replace the

contact glass assembly.

(see page 1-3-55)

10

ISC PWB

The ISC PWB is defective.

Replace the ISC PWB and perform U411.

(see page 1-3-173)

11

CCD PWB

The CCD PWB is defective.

Replace the ISU and perform U411.

(see page 1-3-173)

12

Main PWB

The main PWB is defective.

Replace the main PWB.(see page 1-5-72)

Defective part

Check description

Corrective Action

1

Original document

Check whether the original

document is dirty.

If the original document is dirty, replace.

2

Original document

Check if the size of the original

document and its reference size

match.

If the size of the original document and its

reference size do not match, set the correct

document size or activate border erasure.

3

Scanning position

of the DP

Check whether the scanning

position of the DP is wrong.

If the scanning position of the DP is shifted,

perform maintenance mode U068, DP Read.

(see page 1-3-60)

4

Adjustment of the

scanner

Check whether the outer areas

of the original document have

streaks or lines.

1. Perform maintenance mode U072, Front.

(see page 1-3-65)

2. Perform maintenance mode U411, DP

Auto Adj.

3. Perform maintenance mode U411, DP

FaceUp(Chart2)_Input.

(see page 1-3-173)

5

Slit glass, Contact

glass

Check whether the slit glass and

contact glass are dirty.

If the slit glass and contact glass are dirty,

clean the contact glass, the slit glass, the

bottom part of the shading plate, and the

conveying guide.

6

Mirror

Check whether the mirrors are

dirty.

If the mirrors are dirty, clean the three mirrors.

7

Lamp unit

Check that the lamp unit is con-

taminated with dusts.

If dusts are observed on the lamp unit, remove

the dusts in the light paths.

8

CCD sensor

Check that the CCD sensor

glass is contaminated with dusts.

If dusts are observed on the CCD sensor

glass,remove the dusts by an air blower.

Defective part

Check description

Corrective Action

Summary of Contents for TASKalfa 3051ci

Page 5: ...2L6 2N6 2N5 2N4 1 4 4 Machine Option2 Figure 1 4 4 Paper jam location Matchine Option2 ...

Page 201: ...2L6 2N6 2N5 2N4 5 1 4 200 ...

Page 202: ...2L6 2N6 2N5 2N4 5 1 4 201 ...

Page 203: ...2L6 2N6 2N5 2N4 5 1 4 202 ...

Page 204: ...2L6 2N6 2N5 2N4 5 1 4 203 ...

Page 257: ...2L6 2N6 2N5 2N4 5 1 4 256 16 Grainy image See page1 4 272 ...