2L6/2N6/2N5/2N4

1-4-262

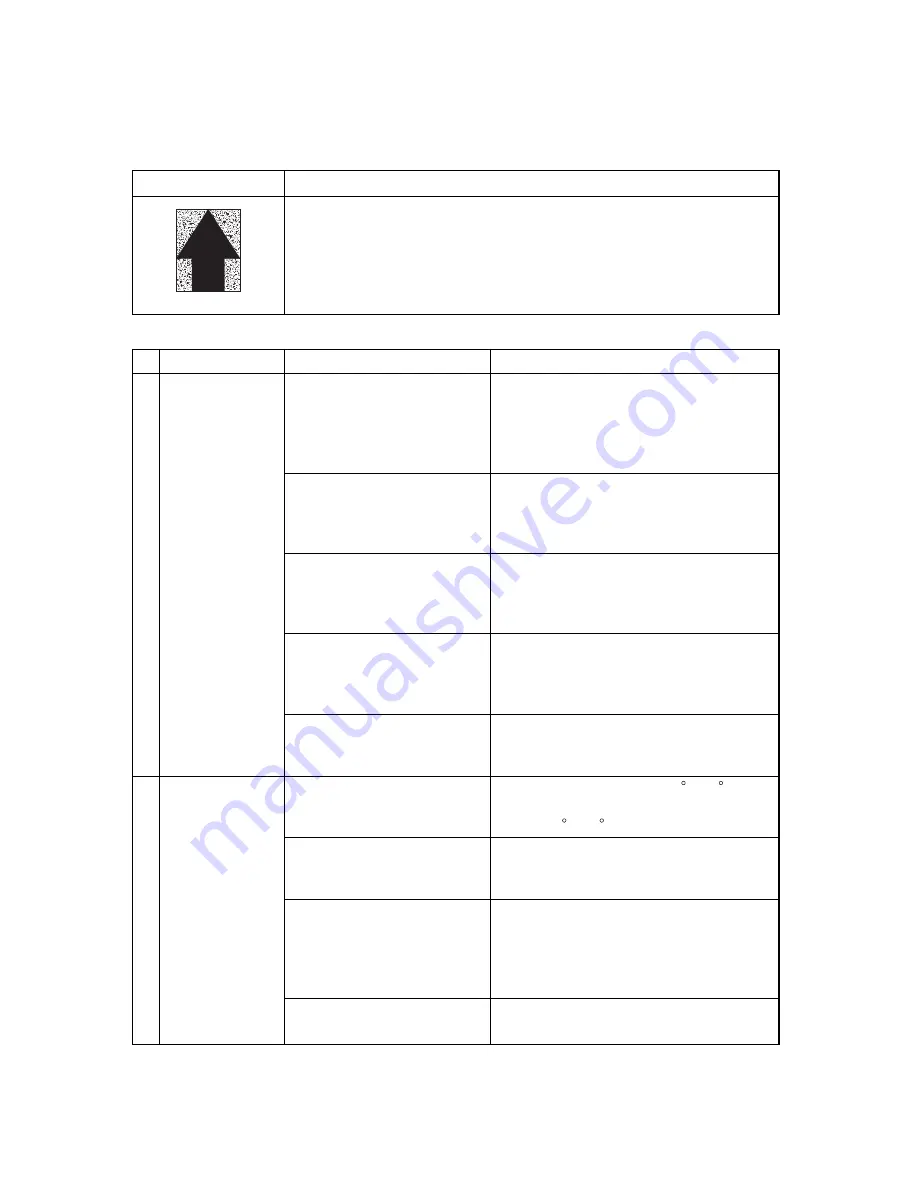

(4) The background is colored.

Print example

Cause of trouble

1. Toner is deteriorated in quality (under-charged).

2. Toner is over-supplied.

3. Developing bias is too high.

4. The layer of toner is too thick on the developing roller (too much toner).

5. The surface potential of the drum is too low (under low temperature

environment).

Defective part

Check description

Corrective Action

1

Developer unit

Executing U089 to generate

four-color PGs and check the

following with the color which is

defective:

(see page 1-3-70)

1. Check whether the device

was being continuously

operated with high density,

under a hot environment.

If the device was being continuously operated

with high density under a hot environment,

perform developing refreshing. (System Menu

>Adjustment / Maintenance)

2. Check the value of the U140

developer bias. (see page 1-

3-99)

If the density ID is too low at calibration,

execute maintenance modes U464 Calibration

and U410 Grascale Adjustment. (see page 1-

3-197,1-3-172)

3. Check contamination and

deformation on the

connecting terminals for

developer bias.

If the connecting terminals for developer bias

are dirty, clean.If the connecting terminals are

deformed, correct for a proper conduction.

4. Check the toner sensor

output by U155.

(see page 1-3-107)

If the toner sensor output obtained by U155 is

100 or less, replace the developer unit. (see

page 1-5-57)

2

Drum unit

1. Execute U139 to check the

internal temperature.

(see page 1-3-98)

If the internal temperature is 16 C/ 61 F or

less, continue printing until the temperature

reaches 16 C/ 61 F or higher.

2. Check the value of the main

high voltage by U100.

(see page 1-3-74)

Fix the inner unit properly.

(see page 1-5-55)

3. Check that the ground

terminal is not contaminated

or the conductive grease is

not applied with the

connecting terminals.

If the connecting terminals are dirty, clean.

If the amount of the grease applied is too

small, apply conductive grease to the bearing

on the receiver side of the drum drive axle.

Replace the drum unit. (Perform U119)

4. Check if the charging roller is

dirty.

If the charging roller is dirty, clean.Or replace it.

(Perform U930)(see page 1-3-230)

Summary of Contents for TASKalfa 3051ci

Page 5: ...2L6 2N6 2N5 2N4 1 4 4 Machine Option2 Figure 1 4 4 Paper jam location Matchine Option2 ...

Page 201: ...2L6 2N6 2N5 2N4 5 1 4 200 ...

Page 202: ...2L6 2N6 2N5 2N4 5 1 4 201 ...

Page 203: ...2L6 2N6 2N5 2N4 5 1 4 202 ...

Page 204: ...2L6 2N6 2N5 2N4 5 1 4 203 ...

Page 257: ...2L6 2N6 2N5 2N4 5 1 4 256 16 Grainy image See page1 4 272 ...