2L6/2N6/2N5/2N4

1-4-44

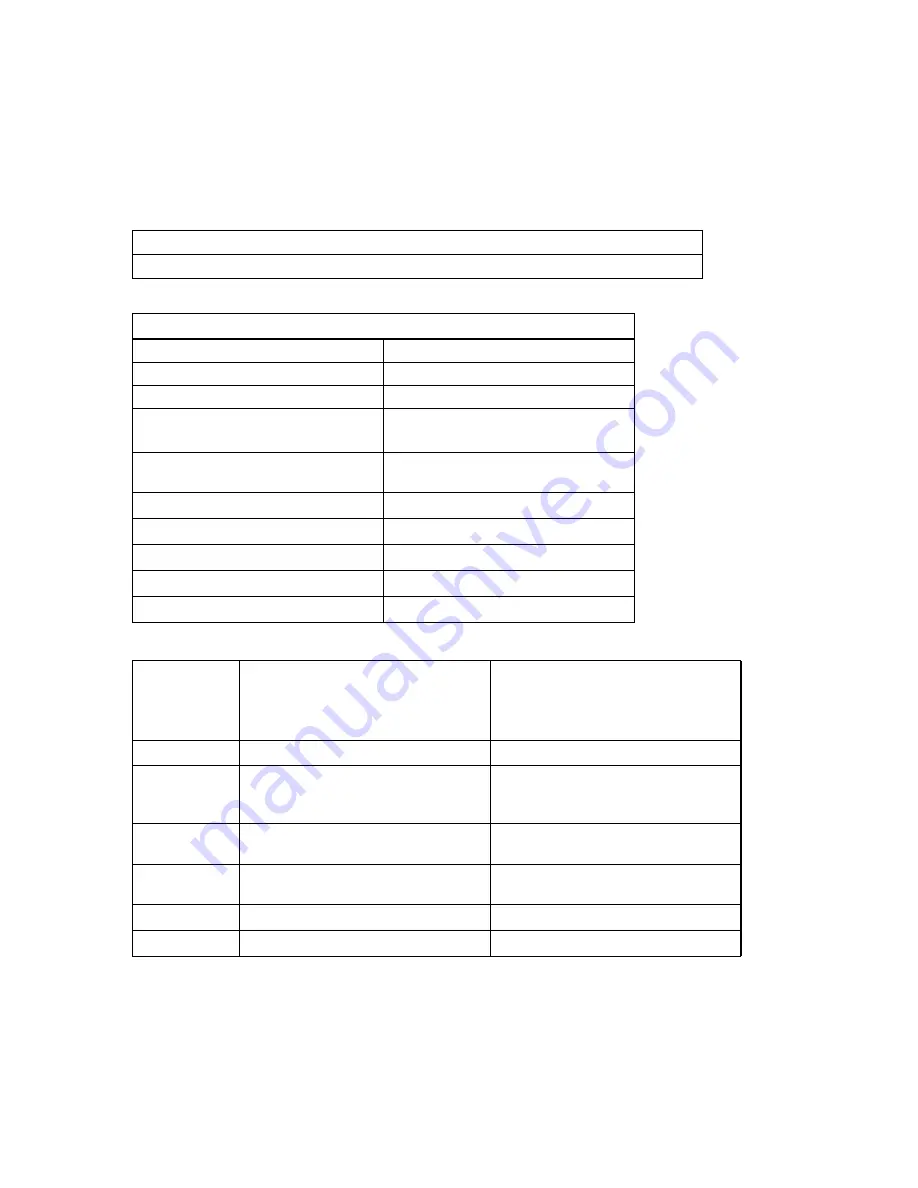

(4) Paper jam at feeding from cassette 2

Electrical parts that could cause paper jam during paper travelling at the primary

feeding (to regist roller)

Timing of detection

Corrective Action

*1: 30 ppm model /35 ppm model only. *2: 45 ppm model /55 ppm model only.

Jam code

J0502,J0512,J1302,J1312,J1502,J1512,J4002,J4012

Related parts

Paper feed motor(PFM)

Engine PWB (EPWB)

Paper feed clutch 2 (PFCL2)

Feed PWB 2 (FPWB2)

Assist clutch 2 (ACSL2)

*2

Feed PWB 1 (FPWB1)

Middle clutch (MCL)

*1

Middle motor (MM)

*2

Registration clutch (RCL)

*1

Registration motor (RM)

*2

Vertical conveying clutch (PCCL)

Feed sensor 2 (FS2)

Paper conveying sensor (PCS)

Middle sensor (MS)

Registration sensor (RS)

Checking

procedure at the

occurrence of

J05X2

Corrective action at the occurrence of

J05X2

On/Off control signal output connector

(terminal), point of checking connection

1

Items for Initial Checks

see page 1-4-29

2

Feed sensor 1 (FS1): Conduct

connectivity check, mounting location

check, operation check (U031)

Feed PWB 2 YC8-23

3

Paper feed clutch 2 (PFCL2): Operation

check (U032)

Feed PWB 2 YC4-1

4

Paper feed motor : Operation check

(U030)

Feed PWB 2 YC2-3(RDY), 5(REM)

5

Feed PWB 2: Replace

6

Engine PWB : Replace

Summary of Contents for TASKalfa 3051ci

Page 5: ...2L6 2N6 2N5 2N4 1 4 4 Machine Option2 Figure 1 4 4 Paper jam location Matchine Option2 ...

Page 201: ...2L6 2N6 2N5 2N4 5 1 4 200 ...

Page 202: ...2L6 2N6 2N5 2N4 5 1 4 201 ...

Page 203: ...2L6 2N6 2N5 2N4 5 1 4 202 ...

Page 204: ...2L6 2N6 2N5 2N4 5 1 4 203 ...

Page 257: ...2L6 2N6 2N5 2N4 5 1 4 256 16 Grainy image See page1 4 272 ...