2L6/2N6/2N5/2N4

1-4-46

*1: 30 ppm model /35 ppm model only. *2: 45 ppm model /55 ppm model only.

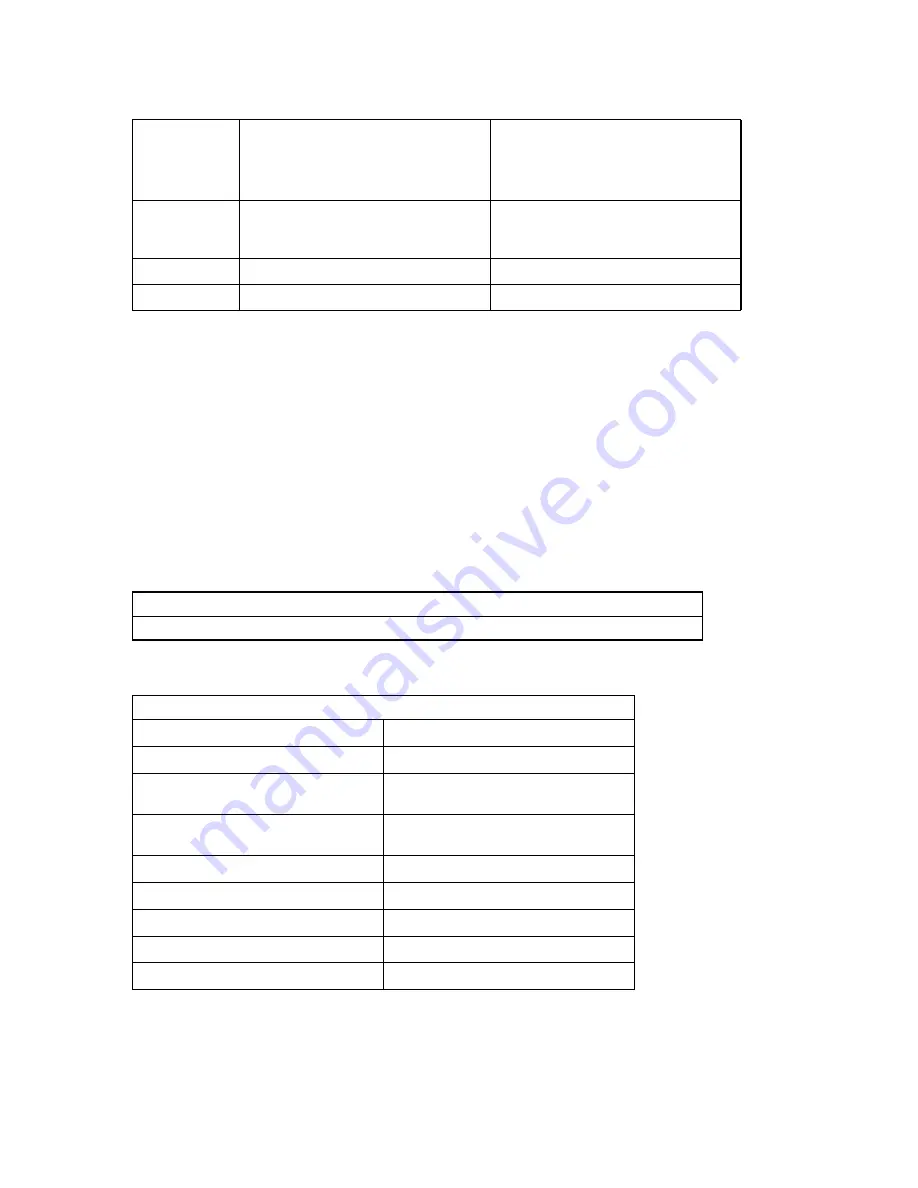

(5) Paper jam during manual feeding

Electrical parts that could cause paper jam during paper travelling at the primary

feeding (to regist roller)

Timing of detection

Corrective Action

*1: 30 ppm model /35 ppm model only. *2: 45 ppm model /55 ppm model only.

3

Registration clutch (RCL)

*1

Registration motor (RM)

*2

: Operation

check (U032/30)

Feed PWB 1 YC22-2 / YC25-1 to 4

4

Feed PWB 1 : Replace

5

Engine PWB : Replace

Jam code

J0131,J0509,J0519,J4009,J4019

Related parts

Paper feed motor(PFM)

Engine PWB (EPWB)

Manual feed clutch (MPPFCL)

Feed PWB 1 (FPWB1)

Middle clutch (MCL)

*1

Middle motor (MM)

*2

Relay PWB (RYPWB)

* : In paper conveying unit

Registration clutch (RCL)

*1

Registration motor (RM)

*2

MP feed sensor (MPFS)

Registration sensor (RS)

Manual feed lift motor (MPLM)

MP lift sensor 1 (MPLS1)

MP lift sensor 2 (MPLS2)

Checking

procedure at the

occurrence of

J40X2

Corrective action at the occurrence of

J40X2

On/Off control signal output connector

(terminal), point of checking connection

Summary of Contents for TASKalfa 3051ci

Page 5: ...2L6 2N6 2N5 2N4 1 4 4 Machine Option2 Figure 1 4 4 Paper jam location Matchine Option2 ...

Page 201: ...2L6 2N6 2N5 2N4 5 1 4 200 ...

Page 202: ...2L6 2N6 2N5 2N4 5 1 4 201 ...

Page 203: ...2L6 2N6 2N5 2N4 5 1 4 202 ...

Page 204: ...2L6 2N6 2N5 2N4 5 1 4 203 ...

Page 257: ...2L6 2N6 2N5 2N4 5 1 4 256 16 Grainy image See page1 4 272 ...