2KR/2KS

1-5-31

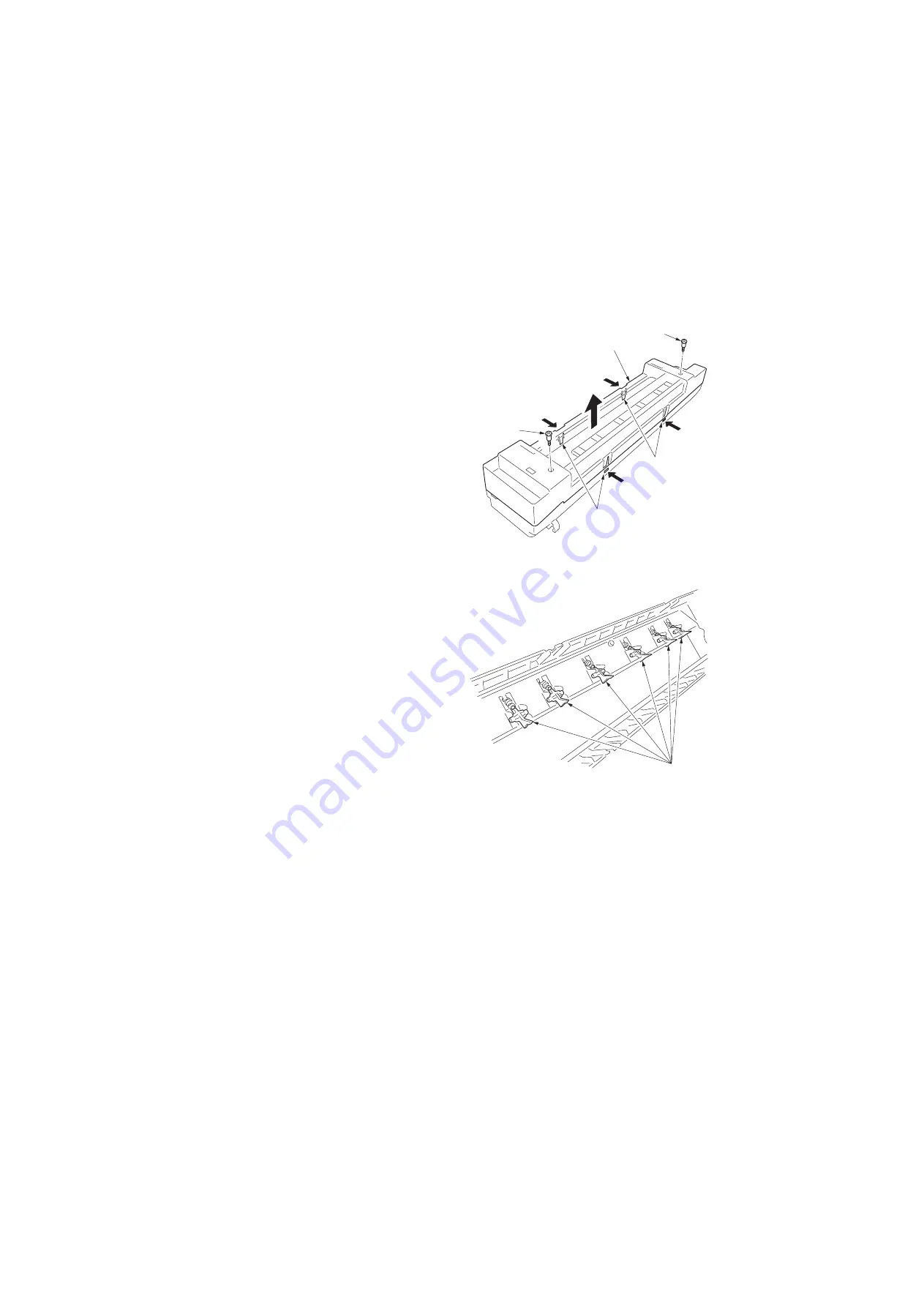

(2) Detaching and refitting the heat roller separation claws

Follow the procedure below to replace the heat roller separation claws.

Procedure

1. Remove the fuser unit (see page 1-5-30).

2. Remove the two pins and remove the upper

fuser cover while holding the four claws.

Figure 1-5-62

3. Remove the heat roller separation claws

from the upper fuser cover.

4. Replace the heat roller separation claws and

install the claws to upper fuser cover.

5. Refit the upper fuser cover.

6. Refit the fuser unit.

Figure 1-5-63

Upper fuser cover

Pin

Pin

Claws

Claws

Heat roller

separation claws

Summary of Contents for TASKalfa 420i

Page 1: ...SERVICE MANUAL Published in May 2010 842KS113 2KSSM063 Rev 3 TASKalfa 420i TASKalfa 520i ...

Page 4: ...This page is intentionally left blank ...

Page 10: ...This page is intentionally left blank ...

Page 14: ...2KR 2KS This page is intentionally left blank ...

Page 224: ...2KR 2KS 1 4 66 This page is intentionally left blank ...

Page 328: ...2KR 2KS 2 3 30 This page is intentionally left blank ...

Page 371: ...INSTALLATION GUIDE FOR PAPER FEEDER ...

Page 381: ...INSTALLATION GUIDE FOR 3000 SHEETS PAPER FEEDER ...

Page 436: ...INSTALLATION GUIDE FOR CENTER FOLDING UNIT ...

Page 450: ...INSTALLATION GUIDE FOR MAILBOX ...

Page 458: ...INSTALLATION GUIDE FOR HOLE PUNCH UNIT ...

Page 470: ...INSTALLATION GUIDE FOR BUILT IN FINISHER ...

Page 483: ...INSTALLATION GUIDE FOR JOB SEPARATOR ...

Page 491: ...INSTALLATION GUIDE FOR FAX System ...

Page 507: ......

Page 508: ......