237

English

Operation instructions

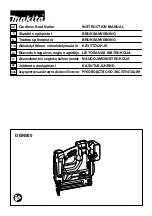

Load and unload the fuel cell

• Open the fuel cell door by pulling the door and

rotate

•

Insert the fuel cell into the chamber. Align the fuel

cell nozzle to the fuel stem on the gas tool.

•

Close the fuel cell door.

Load and unload the fastener

•

Insert battery and fuel cell before you load the fas

-

teners. If you load the fastener before the battery

and/or fuel cell is connected, the fastener may be

shoot out accidentally.

•

Point the nozzle away from any personnel and

keep your finger away from the trigger when load

-

ing the fastener.

For magazine without stopper

•

To load the fastener, slide in the fastener strip into

the magazine

•

Push the release lever and pull the pusher until it

is behind the fastener strip.

•

Gently release the pusher to engage the fastener

strip

•

To unload the fastener from the magazine, press

the release lever on the pusher and tilt the gas

tool to slide the fastener strip to the rear end of the

magazine.

•

Unload the fastener strip by sliding out the fastener

strip.

For 3 steps magazine design, follow the same

safety precaution and continue with following

steps

•

To load fasteners, pull the pusher to the rear until it

is locked to the magazine at rear position.

•

Slide fastener strip into the magazine.

•

Gently release the pusher to engage the fastener

strip

•

To unload the fastener from the gas tool, pull

the pusher to the rear locking position. Slide the

fastener out of the magazine.

Depth of drive adjustment

• The gas tool is equipped with a depth of drive

adjustment. Test the depth of drive on scrap piece

before you start your work.

• Turn the knob to adjust the depth of drive.

• Repeat above procedure until you find your de

-

sired depth of drive setting.

Specific for concrete nailer; push the slider

sidewards to adjust the depth.

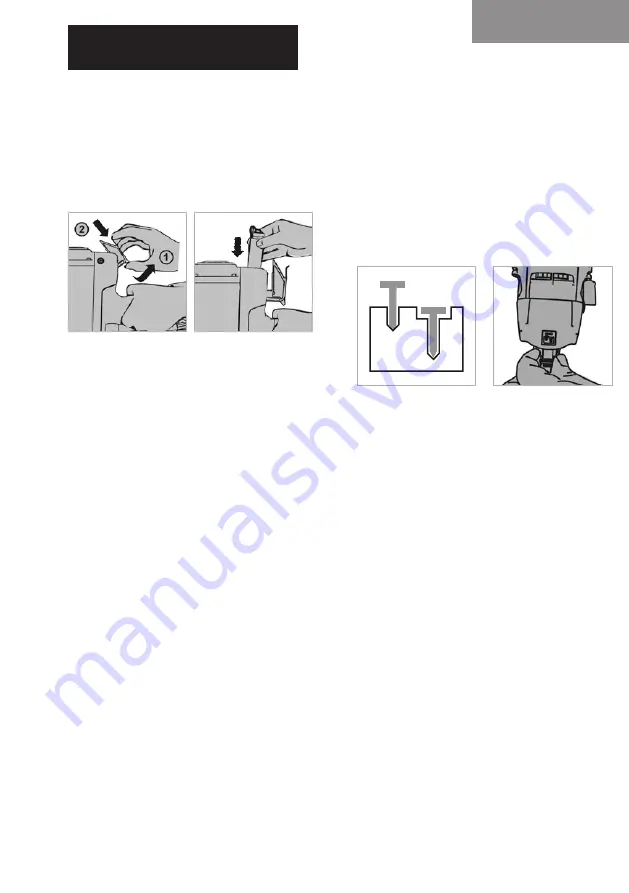

Actuating the gas tool

• The gas tool is equipped with a full sequential

actuation system only.

• To actuate the gas tool, depress the safety against

the workpiece, and then pull the trigger.

• To actuate the gas tool again, you will need to re

-

lease the safety fully and release the trigger before

you repeat above procedure.

• Make sure you are driving against workpiece

before you pull the trigger.

Operating the gas tool

• To ensure proper operation and avoiding overheat

-

ing or choking of the gas tool, driving pace should

not exceed 1,000 shots/h and 4,000 shots/day at

optimal working conditions. High temperatures

and/or high altitudes will decrease the feasible

mamimum number of shots per day.

Jam clearing for framing nailers and

staplers

• In the case of fastener jam, disconnect the fuel cell

and battery before you perform any actions.

Summary of Contents for TJEP GRF 34/90 GAS 3G

Page 2: ...www tjep eu...

Page 4: ...2 2 3 6 6 7 7 7 7 8 8 8 9 9 9 9 LED 9 10 10 11 TJEP...

Page 5: ...3 CE CE CE...

Page 6: ...4 49 C 120 F...

Page 7: ...5 Kyocera Unimerco Fastening Kyocera Unimerco Fastening...

Page 10: ...8 3...

Page 11: ...9 1000 4000 2 Phillips TJEP TJEP ST 15 50 GAS 2 TJEP ST 15 50 GAS LED 2 1 LED LED LED...

Page 80: ...78 78 79 82 82 83 83 84 84 84 84 84 85 85 85 85 LED 85 86 86 87 TJEP...

Page 81: ...79 CE CE CE...

Page 82: ...80 49 C 120 F...

Page 83: ...81 Kyocera Unimerco Fastening Kyocera Unimerco Fastening...

Page 86: ...84 3...

Page 87: ...85 1 000 4 000 2 TJEP TJEP ST 15 50 GAS 2 TJEP ST 15 50 GAS LED 2 1 LED LED...

Page 243: ...www tjep eu EXPLORE OUR WEBSITE FOR MORE INFORMATION...