Safety Warnings .................................................................... 1

Introduction ........................................................................... 1

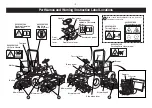

Part Names and Warning / Instruction Label Locations ........ 2

Warning Labels and Instruction Labels ................................. 3

LM282 / LM319 Features ...................................................... 4

Specifications ........................................................................ 4

Operation .............................................................................. 5

1. Inspection before use

...................................... 5

1-1 Clean the radiator and oil cooler

............... 5

1-2 Inspect the radiator and the water coolant quantity

...... 5

1-3 Inspect and refill the engine oil .................................. 5

1-4 Inspect the hydraulic oil ............................................ 5

1-5 Clean the air cleaner ................................................. 6

1-6 Inspect around the engine ........................................ 6

1-7 Inspect the tires ......................................................... 6

1-8 Inspect the brakes

.................................... 6

2. Tighten all parts ............................................................... 6

3. Machine Operation .......................................................... 7

3-1

Machine operation .................................... 7

3-2 Before starting the engine

........................ 7

3-3 Starting up and shutting off the engine ..................... 7

3-4 Safety device ............................................................ 7

3-5

Fuel handling precautions ........................ 8

3-6

When leaving the machine

...... 8

3-7 Reel raise/lower lever

............................... 8

3-8 Reel rotation lever

.................................... 8

3-9 Reel reverse-rotation prevention stopper

.... 8

3-10 Side brake ............................................................... 8

3-11 Unload valve

........................................... 9

3-12 Stop valve

............................................... 9

3-13 Reel rotation/stop changeover lever

....... 9

3-14 Adjusting the seat .................................................. 10

Caution

Caution

Caution

Caution

Caution

Caution

Caution

Caution

Danger

Caution

Caution

Danger

Warning

Caution

Caution

3-15 Mower lock lever (LM282 only) .............................. 10

4. Operating the machine

.................. 10

5. Gauges........................................................................... 11

5-1 Water temperature gauge ........................................ 11

5-2 Hour Meter

.............................................. 11

5-3 Fuel Gauge

.............................................. 11

5-4 Oil Pressure Lamp ................................................... 11

5-5 Charge Lamp ........................................................... 11

6. Inspection and Maintenance .......................................... 12

6-1 Changing Engine Oil

............................... 12

6-2 Changing Hydraulic Oil

............................ 12

6-3 Applying Grease ...................................................... 12

6-4 Inspecting for Leaks................................................. 12

6-5 Inspecting the Battery

............. 13

6-6 NTN Constant-Velocity Joints

................. 13

7. Maintenance Cautions ................................................... 13

7-1 Maintenance

procedures

........ 13

7-2

Preventing injuries from high-pressure oil ....... 13

7-3 Maintenance Schedule ............................................ 14

7-4 Maintenance schedule and specified values ........... 14

8. Mower adjustment.......................................................... 15

8-1 Cutting height........................................................... 15

8-2 Blade adjustment

.................... 15

8-3 Lapping

.................................................... 16

9. Precautions for machine operation ................................ 16

9-1 hot

parts .................................................. 16

9-2 Reel

mower ............................................. 16

9-3

Raising the unit........................................ 16

10. Working on a slope ...................................................... 17

10-1

Precautions when working on a slope... 17

11. Safe operation.............................................................. 17

11-1 Safety

clothing....................................... 17

Warning

Caution

Caution

Danger

Caution

Caution

Danger

Caution

Warning

Caution

Caution

Caution

Danger

Caution

Caution

Caution

Danger

Caution

Warning

Caution

11-2

When not to operate the unit ................ 17

11-3

When lending the machine to another person ..... 17

11-4

Do not modify the machine.................... 17

11-5

Remove debris from around the muffler and engine..... 17

11-6

Do not operate the machine at night ..... 17

11-7

Do not drive on public roads.................. 18

12. Long-term storage........................................................ 18

Hydraulic circuit diagram (LM282/LM319) ........................... 19

Electrical system (for both models) ...................................... 21

Parts Catalogue ................................................................... 23

1. Frame parts.................................................................... 24

2. Cover parts..................................................................... 26

3. Front wheel parts ........................................................... 30

4. Rear wheel parts ............................................................ 32

5. Pedal parts ..................................................................... 34

6. Engine parts ................................................................... 36

7. Hydraulic parts A (power steering, cylinder system) ...... 40

8. Hydraulic parts B (reel motor system)............................ 44

9. Hydraulic parts C (wheel motor system) ........................ 48

10. Mower lift arm parts...................................................... 52

11. Mower parts (LM282/#1, #2, #4, LM319/#1, #3) .......... 54

12. Mower parts (LM282/#3, #5 LM319/#2) ....................... 58

13. Roller assembly parts................................................... 62

14. Accessory parts............................................................ 64

15. Option........................................................................... 64

Caution

Warning

Warning

Caution

Caution

Warning

CONTENTS