6

2.

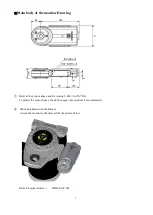

How to Install

The tip montitor MUST NOT BE used with a Tip Dresser made by companies other than KYOKUTOH.

A cap tip dressed by dressers from another company may not be discriminated properly by the monitor.

Please check the manual of the dresser before installing.

When installing the tip monitor to the dresser, please be sure it is being done in a proper way.

Also, to protect the tip monitor from the shock caused during gun pressure, we recommend the usage of

EQUALIZINGS.

Please DO NOT place the monitor in which it can be interfered by cables, hoses, welding robots, etc.

Please make sure the welding gun DOES NOT interfere with the monitor’s LAN cable.

It can be a cause of cable damage.

*

Place to install the monitor

Please set the monitor to places where there is no contact with water.

Please set the monitor to places where there is no contact with the cooling water during the replacement of

the tip.

If possible, please set the monitor to place far from the spatter.

Please protect the LAN cable by things such as flexible conduit tubes, etc.

Summary of Contents for TM01-KP-00A

Page 16: ...13...

Page 18: ...15...

Page 36: ...33 When finished click OK Click Save Before Adjusting After Adjusting...

Page 49: ...46 MEMO...

Page 51: ...48...