28

Do not place product in cases until it is at proper operating temperature. Air discharge and return flues

must remain open and free of debris or obstruction at all times to provide proper refrigeration and air

current performance. Do not allow any product, signs, debris, etc. to block these grilles. Do not use any

non-approved shelving, display racks or any accessory that could hamper air current performance.

WARNING!

Do not walk on top of the cases!

This could result in damage to the case and serious

personal injury could occur. These cases are not designed to support excessive external weight. Do not

use top of cases for storage.

Normal Operation

Below are the different operation methods for our cases. Cases vary depending on application and how

they were specifically ordered. Review the data plate on your cases and refer to the Case Data previously

listed in this manual for your models specific information.

1.

Off-Cycle Defrost. The fans run continuously and defrost termination is by termination Klixon.

2.

Electric Defrost models are optional. Electric heaters are utilized to melt the frost and ice on the

coil. The heaters are located in the air stream in front of the coil. The defrost cycle is time

initiated and should be temperature terminated. Case fans operate continuously in defrost and

refrigeration. As a safety precaution, a safety cutoff Klixon is wired in this series with the

defrost heater set to turn the heater off at temperatures above 70°F.

3.

Hot Gas Defrost models are optional for parallel compressor operation only. Hot gas is routed

through the suction line and evaporator coil. It exits the coil through a by-pass around the

expansion valve and heat exchanger, in order to return to the liquid line. The condensed

liquid is then used to feed the other cases on the parallel case. The display case’ fans continue

to operate during defrost to warm up the drain pan and air ducts. The defrost cycle is time-

initiated and should be temperature terminated.

4.

Single Condensing Case Systems. A thermostat should be used to control case temperatures. The

thermostat bulb should be mounted in the discharge air.

NOTE

: Heat exchangers are standard in hot gas defrost models. They aid in increasing operating

efficiency and reducing frosting and flood-back to the compressor. Heat exchangers may not be used if

mechanical subcooling is incorporated in the system design.

Cleaning

As a general rule, always use mild soap and water to wipe the case down. Special precautions must be

taken when cleaning some components of the case.

Exterior surfaces should be cleaned with warm water and mild soap to protect and maintain the finish.

Do

not use cleaners containing abrasive materials or ammonia, which will scratch or dull the finish.

The waste outlet should be flushed with water following each cleaning.

Interior surfaces may be cleaned with most mild soap formulas, as well as ammonia based cleaners and

sanitizing solutions. These cleansers should not harm the interios surface.

WARNING!

Always shut power off during the cleaning process. Cleaning the case with

electrical power applied is a shock hazard that may cause serious injury or death.

Summary of Contents for QILG 06

Page 2: ...2 ...

Page 7: ...7 Plan View and Cross Sections QILG Cross Section ...

Page 8: ...8 QILG Plan View ...

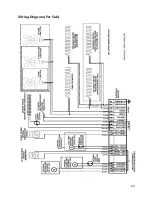

Page 23: ...23 Wiring Diagram Per Side ...

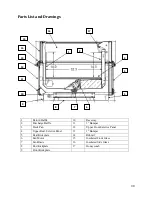

Page 34: ...34 ...

Page 35: ...35 ...