25

Recommended Piping Instructions

1.

Proper size refrigeration lines are essential to good refrigeration performance. Suction lines are

more critical than liquid or discharge lines. Oversized suction lines may prevent good oil

return to the compressor. Undersized lines can rob refrigeration capacity and increase

operating costs.

2.

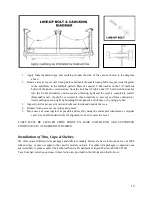

Refrigeration lines in cases in lineups can be reduced. However, the lines should be no smaller

than the main trunk lines in at least 1/3 of the cases and no smaller than one size above the

case lines to the last case. Reductions should not exceed one line size per case. It is preferred

to bring the main trunk lines in at the center of lineup. Liquid lines on systems on hot gas

defrost must be increased one line size above the main trunk line for the entire line-up.

Individual feed lines should be at the bottom of the liquid header. (See proper liquid line

piping diagram).

3.

Do not run refrigeration lines from one system through cases on another system.

4.

Use dry nitrogen in lines during brazing to prevent scaling and oxidation.

5.

Insulate suction lines from the cases to the compressor with 3/4" wall thickness foam on low

temperature cases to provide maximum of 65-degree super heated gas back to the compressor

and prevent condensation in exposed areas. Insulate suction lines on medium temperature

cases with 1/2" thick insulation in exposed areas to prevent condensate dropped.

Summary of Contents for QILG 06

Page 2: ...2 ...

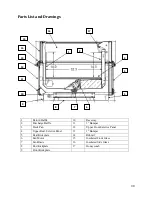

Page 7: ...7 Plan View and Cross Sections QILG Cross Section ...

Page 8: ...8 QILG Plan View ...

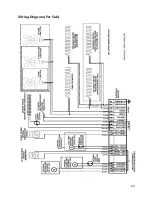

Page 23: ...23 Wiring Diagram Per Side ...

Page 34: ...34 ...

Page 35: ...35 ...