7. Input Spigot Size.

- Insert 2 longitudinal wire in wire die with enough length to measure diameter.

- Reduce Bell at desired diameter, and move P/X Switch#3 and fix screw tight.

8.

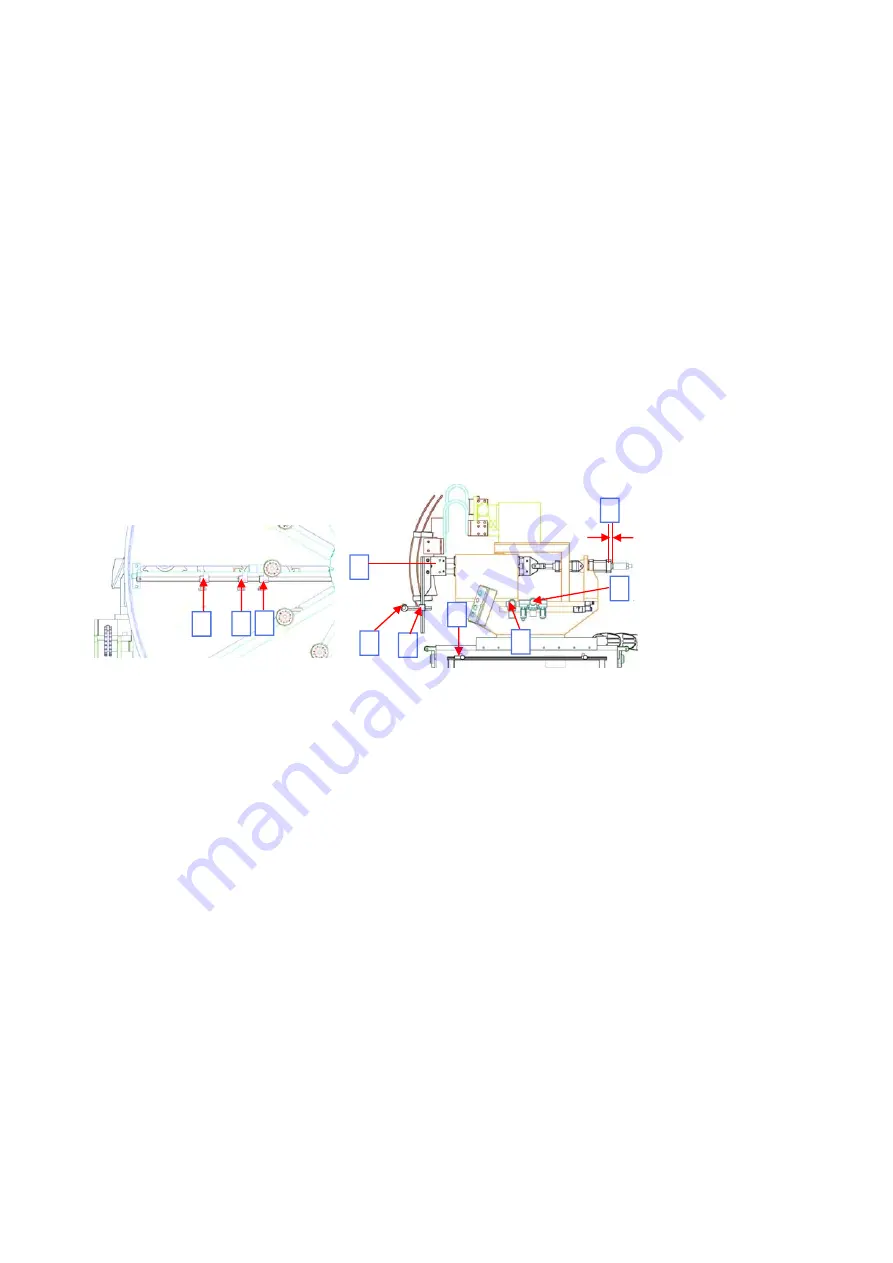

As per above drawing, moves POLE F/W, B/W to makes gap(A) 4~5mm.

- Input digit on Pole Position green bar(Left) same digit as dark green(Right)

※ If Encoder NO USE is selected from MANUAL SCREEN, moves Proximity Switch(#6)

inside and fixed screw.

9. Input Barrel Size.

- BELL Expand as much as desired diameter, and move Spigot Expand Stop P/X Switch #2

and fixed screw.

- Measures distance between outside and outside of wire by a tap, and input digit.

10. Input Bell Size.

- BELL Expand as much as desired diameter, and P/X Switch #1 moved and fixed screw.

12. Push AUTO BACK button for Bell and Pole to be returned back completely.

13. Check Bell, Transfer, Pole bar of Return Complete became green color.

※ If any one bar of them in not green color, START ERROR will be happened.

14. Push WIRE DRUM ON button and adjust Wire Guide Holder (#4 & #5) for round spiral wire.

15. Push DRUM ROTATING button to be positioned at Welding Point(#B).

16. Push CYLINDER button to close Cylinder to contact spiral wire to longitudinal wire.

17. Adjust air pressure of #7 and #8.

- Air pressure should be adjusted according to longitudinal and spiral wire diameter.

Example: 5mm Longitudinal wire x 6mm Spiral wire

#7 Air pressure = 5 bar #8 Air pressure = 3 bar

18. Tuning SLOW Welding Volume on Main Panel at 8.0 in case wire condition same as 14.

- Push RESET button and tuning Fast Welding Volume more than 8.0 (9.0 or 10.0).

- Makes Welding current 0~30.

- Tuning WELDING TIME Volume at 6.0

- 6.0 means 6.0 m/s welding time of 1 point which should be changed as per Drum r.p.m.

- Welding Time is 0~65m Second. Longer welding time is helpful for good welding, but

jump up one welding point which makes no welding for next point. Set up short time

A

1

2 3

B

4

5

8

6

7

Summary of Contents for KN-1248-G3

Page 3: ......

Page 4: ......

Page 5: ......

Page 6: ......

Page 54: ......

Page 55: ......

Page 57: ......

Page 61: ......

Page 62: ......

Page 63: ......

Page 64: ......

Page 65: ......

Page 66: ......

Page 67: ......

Page 68: ......

Page 69: ......

Page 71: ......

Page 73: ......

Page 75: ......

Page 77: ......

Page 78: ......

Page 79: ......

Page 80: ......

Page 81: ......

Page 82: ......

Page 90: ...MANUAL OF WIRE CUTTING MACHINE MODEL KN 2CT ...

Page 107: ......

Page 108: ......

Page 109: ......

Page 110: ......

Page 111: ......

Page 112: ......

Page 113: ......