K1_RM_EN_2-0

w w w . l - a c o u s t i c s . c o m

31

31

31

31

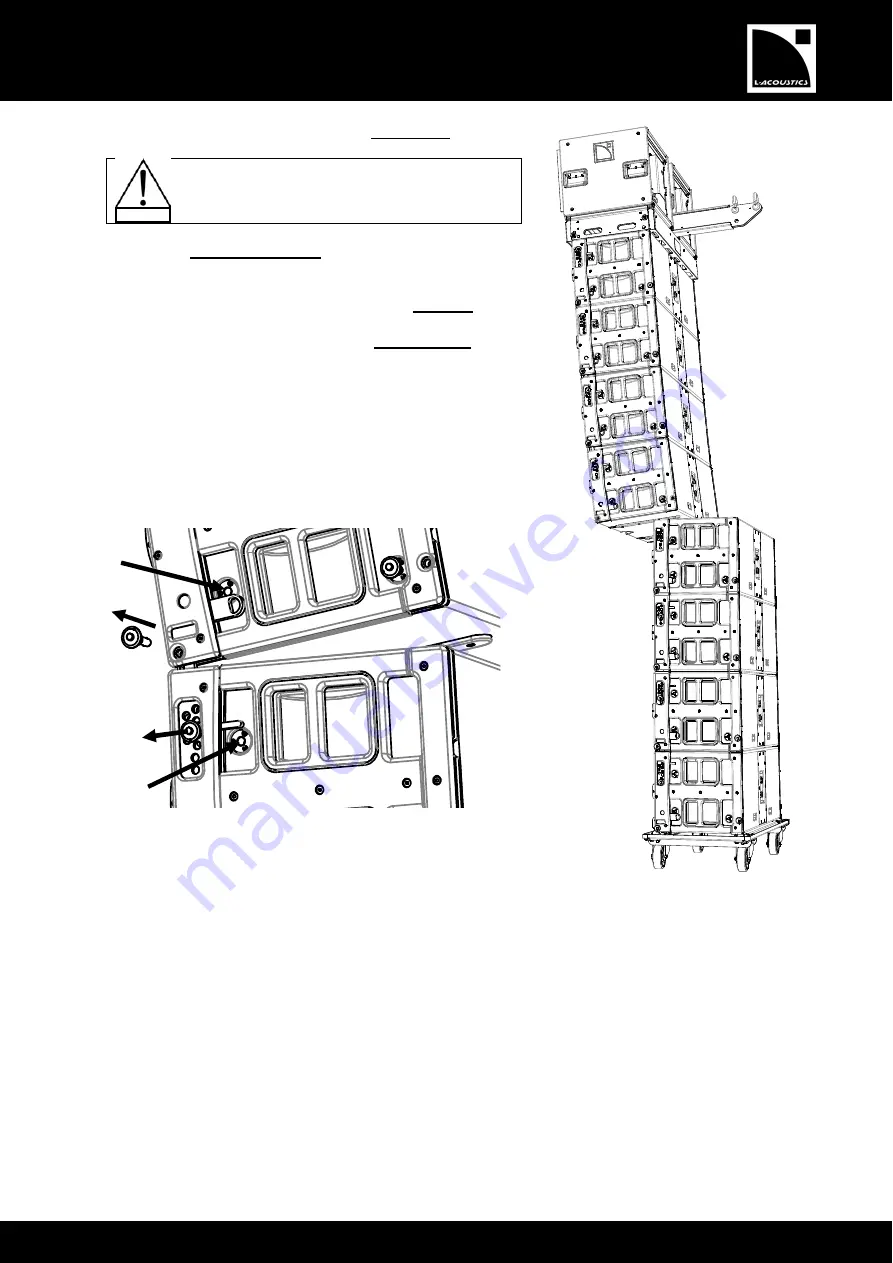

8.

Lower the array until the K1-CHARIOT

four wheels

are laid on

the ground.

Stop lowering the array at the exact moment when

all four bottom enclosure front angles have collapsed.

9.

Detach the

front rigging points

between enclosures #4 and #5

as described below:

a.

On both sides of enclosure#4, remove the

front top

R-BLP.

b.

On enclosure#5, remove both

front bottom

R-BLP

simultaneously (to prevent the array from twisting) and put

them in their storage locations: both angle arms should

automatically slide in.

c.

On both sides of enclosure#4, put the front top R-BLP in its

storage location: the angle arm is locked in shipping position.

Figure 26: Detaching the front rigging points

10.

Remove TOWER#2 from the rigging location.

11.

For arrays of more than 8 enclosures repeat steps 3 to 10 until all TOWERS (but TOWER#1) composing the

array are derigged.

12.

Lower TOWER#1 at 0.5 m/1.5 ft height and attach a K1-CHARIOT to the bottom enclosure as described in step

4.

13.

On both sides of each enclosure of TOWER#1 select the ‘‘variable’’ setting as described in step 7.

WARNING

a.

L

b.

L

c.

L

Summary of Contents for K1

Page 2: ...w w w l a c o u s t i c s c o m ...

Page 68: ...w w w l a c o u s t i c s c o m ...

Page 69: ...w w w l a c o u s t i c s c o m ...

Page 70: ...w w w l a c o u s t i c s c o m ...