Corrective maintenance

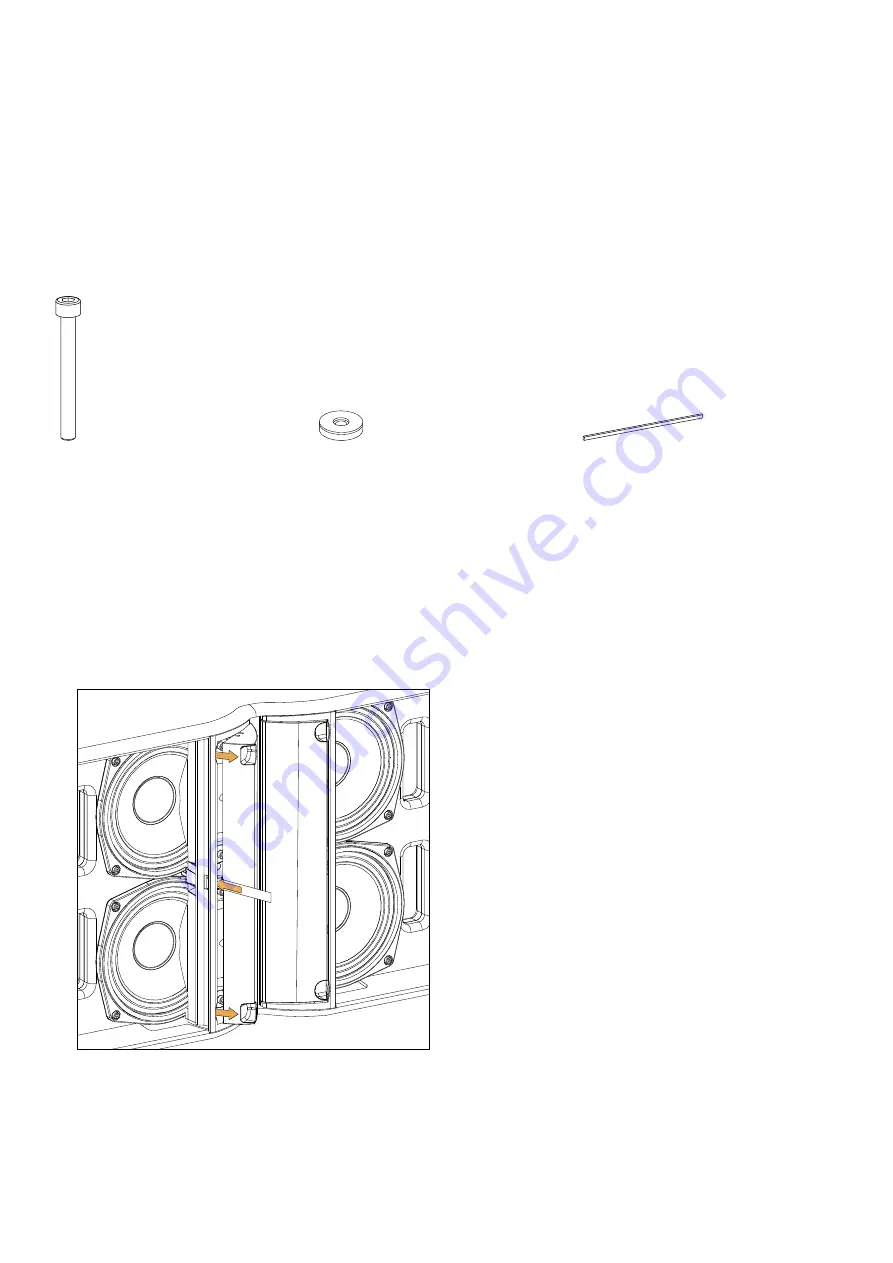

D/R - VARIABLE DIRECTIVITY FINS

Tools

• torque screwdriver

• 4 mm hex bit

• at tool

Repair kit

KR HPFA61

Kit HP FA61 Driver 6.5'' - 8 ohms

×4

×4

×1

S100108

S321

1396

M5×45 hex

washer with gasket

dust cover gasket

Prerequisite

Grill removed.

See

(p.133).

Disassembly

Procedure

1.

Unhook the n with a at tool.

136

K2 owner's manual (EN) version 1.1

Summary of Contents for K2

Page 1: ...K2 owner s manual EN ...

Page 82: ...Rigging procedures 5 Pin the arms 82 K2 owner s manual EN version 1 1 ...

Page 142: ...Corrective maintenance 3 Remove the HF driver assembly 142 K2 owner s manual EN version 1 1 ...

Page 147: ...Corrective maintenance K2 owner s manual EN version 1 1 147 ...

Page 182: ...Pickup points guidelines 182 K2 owner s manual EN version 1 1 ...