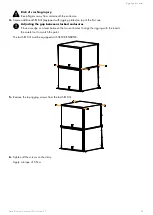

Rigging procedures

Securing a screen

Type of deployment

all deployments, except:

• SB18 IIi secured to KARAIIi-TILT with the angle bracket at the front

• Kara IIi secured to KARAIIi-TILTBRACKET with the angle bracket at the front

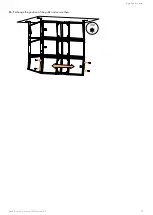

Accessories

SB18IIi-SCREEN for SB18 IIi

KARAIIi-SCREEN for Kara IIi

Screws and fasteners

M6×35 Torx screws (provided)

M6 self-sticking washers for congurations without rigging plates (provided)

Tools

torque screwdriver

T30 Torx bit

Min. number of operators

1

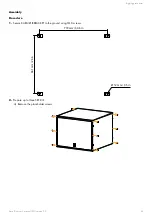

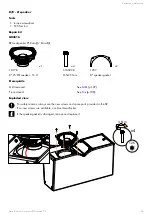

Assembly

Prerequisite

Secure the screens on the enclosures after the array is fully assembled.

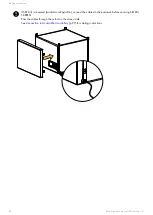

Procedure

1.

Remove the grill screws.

Do not remove the enclosure grills.

Hold the grills in place until the screens are secured.

94

Kara IIi owner's manual (EN) version 2.0