Corrective maintenance

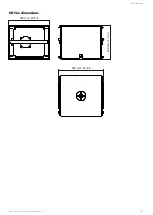

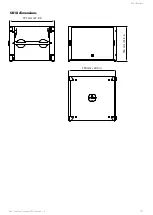

KIBU-SB

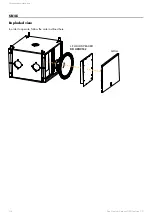

Exploded view

In order to operate, follow the order outlined here. Each assembly refers to the corresponding D/R procedure and the

necessary repair kit(s).

PIN

KR PIN670

LASERMOUNT

KR MBUMPLAS(W)

KR CAMAN12

RUNNERS

KR SB18IPAT

LOCKING TABS

KR WIFOVER(W)

124

Kiva II owner's manual (EN) version 1.0