KIVA SYSTEM

KIVA SB15

m

rigging manual

VERSION 1.1

KIVA-SB15

m

_RM_EN_1.1

w w w . l - a c o u s t i c s . c o m

6

2

MECHANICAL SAFETY

2.1

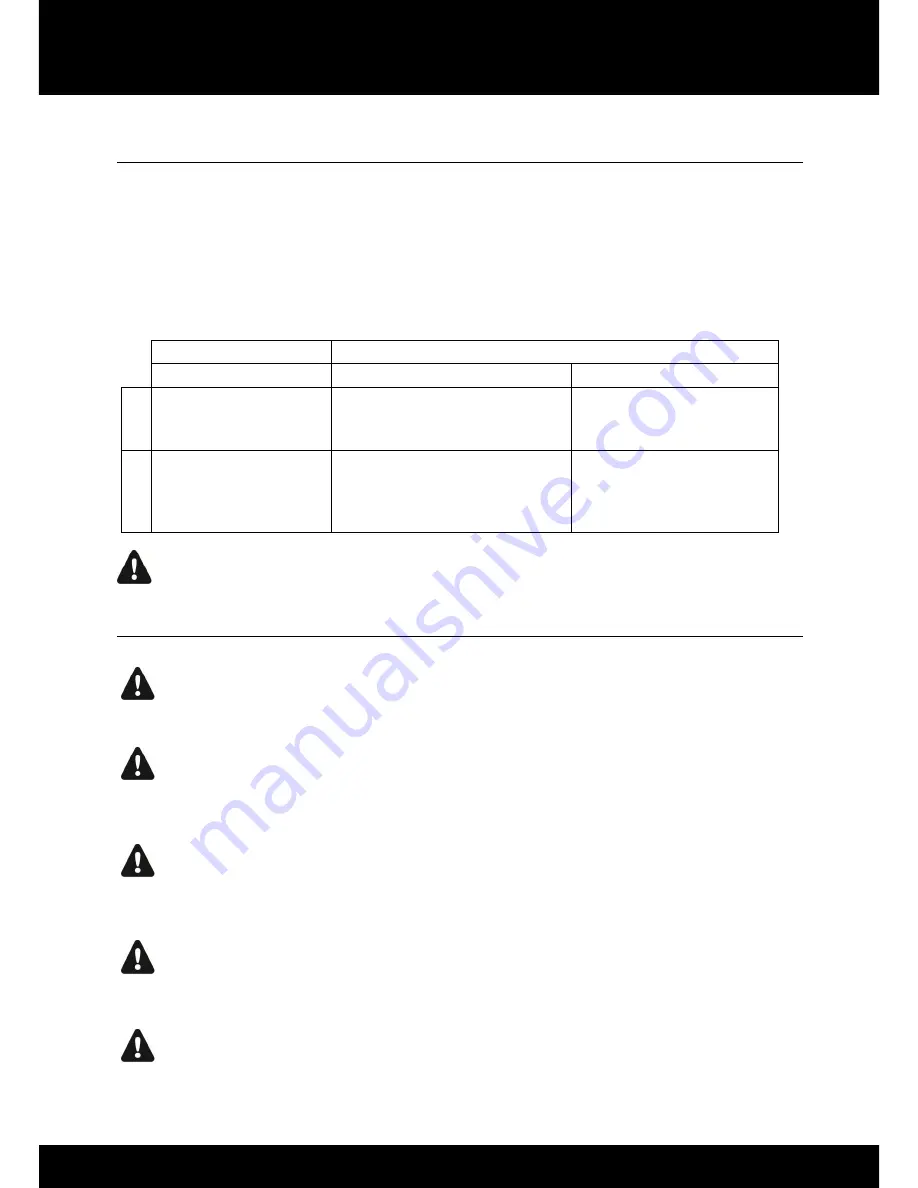

Maximum configurations

The KIVA system rigging complies with BGV-C1 (2012), DIN 18800 and EN ISO 12100-1 (2004) when the following

arrays are deployed.

The safe configurations are always compliant with the standards listed before, regardless of the deployment parameters

(site angles, inter-enclosure angles, etc.).

The maximum configurations correspond to the mechanical limit of the rigging accessories, before deploying these

configurations always model the system in SOUNDVISION and check the

Mechanical Data

section for any

stress

warning

or

stability warning

.

For mixed arrays always refer to your SOUNDVISION model.

Stacking

Flying

With KIBU-SB

With KIBU-SB and shackle WLL 1 t With KIBU-SB and CLAMP250

Safe

2 KIVA

or

8 SB15m

12 KIVA

or

8 SB15m

12 KIVA

or

6 SB15m

Max

imu

m

20 KIVA

or

8 SB15m

20 KIVA

or

8 SB15m

18 KIVA

or

6 SB15m

Mechanical safety of the rigging system

Before any installation, always model the system in SOUNDVISION and check the

Mechanical Data

section for any

stress warning

or

stability warning

.

2.2

Assessing mechanical safety

In order to assess the actual safety of any array configuration before implementation, refer to the following warnings:

Rated working load limit (WLL) is not enough

The rated WLL is an indication of the element resistance to tensile stress. For complex mechanical systems

such as loudspeaker arrays, WLLs cannot be used per se to determine the maximum number of enclosures

within an array or to assess the safety of a specific array configuration.

Mechanical modeling with SOUNDVISION

The working load applied to each linking point, along with the corresponding safety factor, will depend on

numerous variables linked to the composition of the array (type and number of enclosures, splay angles) and

the implementation of the flying or stacking structure (number and location of flying points, site angle). This

cannot be determined without the complex mechanical modeling and calculation offered by SOUNDVISON.

Assessing the safety with SOUNDVISION

The overall safety factor of a specific mechanical configuration always corresponds to the lowest safety factor

among all the linking points. Always model the system configuration with the SOUNDVISION software and

check the Mechanical Data section to identify the weakest link and its corresponding working load. By

default, a stress warning will appear when the mechanical safety goes beyond the recommended safety level.

Safety of ground-stacked arrays in SOUNDVISION

For ground-stacked arrays, a distinct

stability warning

is implemented in SOUNDVISION. It indicates a tipping

hazard when the array is not secured to the ground, stage or platform. It is user responsibility to achieve full

anchorage and to ignore this warning.

Consideration must be given to unusual conditions

SOUNDVISION calculations are based upon usual environmental conditions. A higher safety factor is

recommended with factors such as extreme high or low temperatures, strong wind, prolonged exposition to

salt water, etc. Always consult a rigging specialist to adopt safety practices adapted to such a situation.