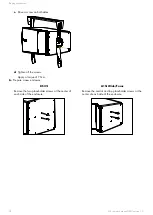

Rigging procedures

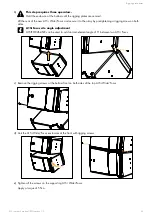

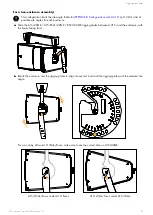

b) Insert the stub at the front of the enclosure.

c) Insert the stub at the rear and secure the rigging axis.

5.

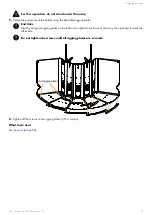

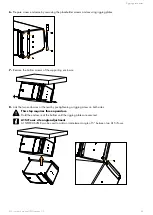

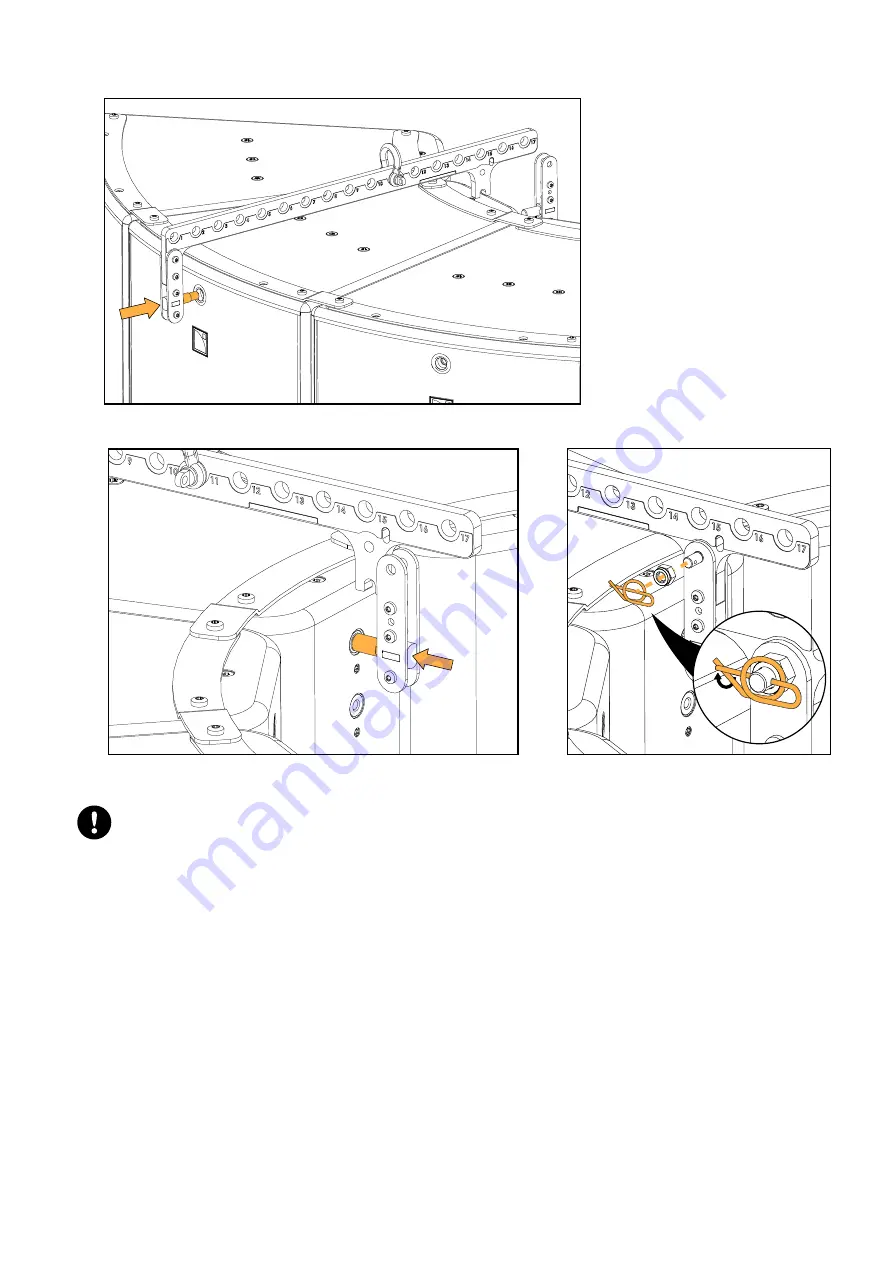

On each A15i-LIFT, secure a shackle to the desired pickup point.

A15i-LIFT pickup point

Select the same pickup point on each A15i-LIFT within an array of up to 6 enclosures.

For larger arrays, refer to

Radial arrays of 7 enclosures and more

(p.112).

6.

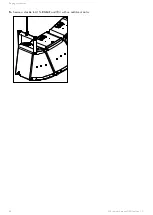

Raise the array until the bottom of the array is easily accessible.

72

A15i owner's manual (EN) version 1.0

Summary of Contents for KS21i

Page 1: ...A15i owner s manual EN ...