Corrective maintenance

D/R - Coaxial loudspeaker

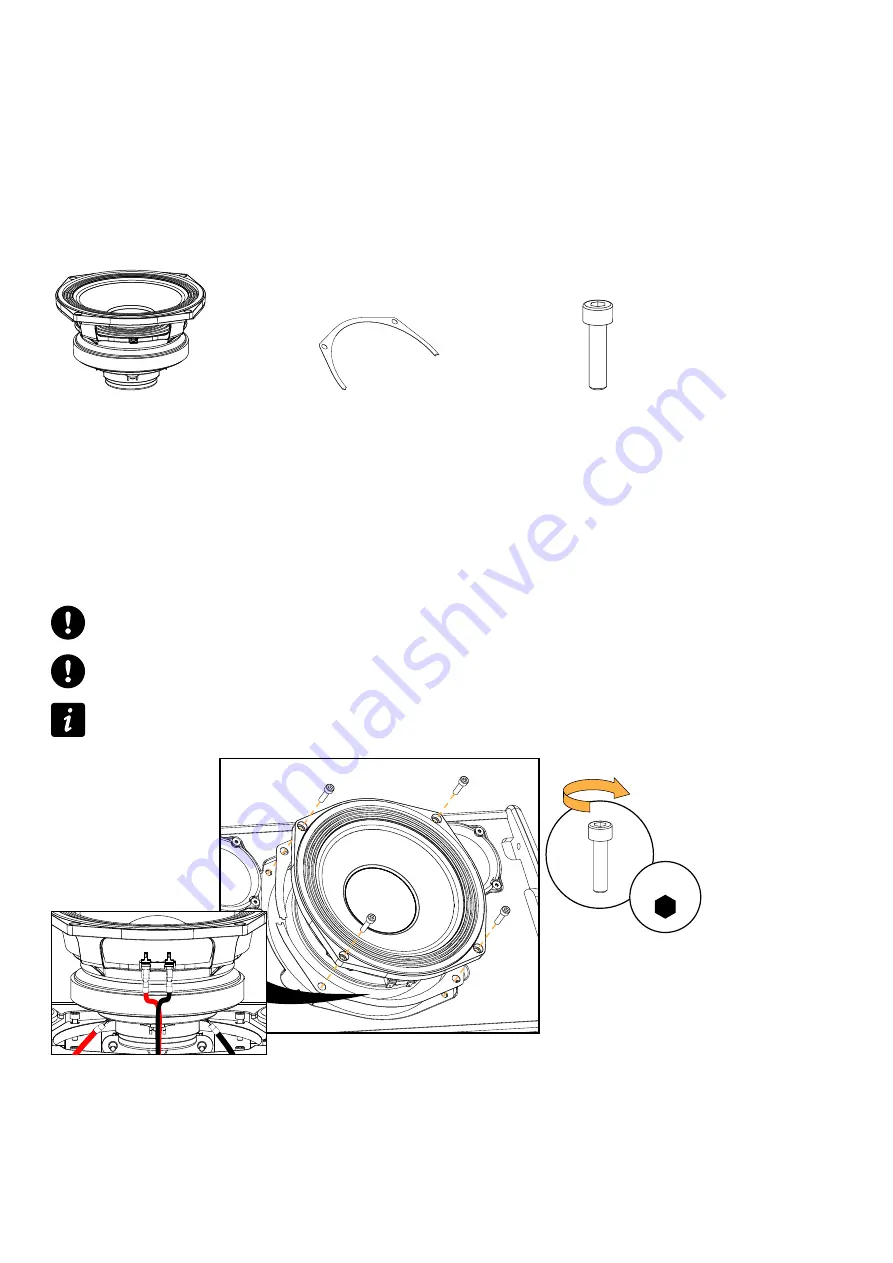

Tools

• torque screwdriver

• 4 mm hex bit

Repair kit

G03170 *

KR coaxial speaker X8

×1

×2

×4

3046

100604

S342

8" coaxial speaker - 8 ohms

8" speaker gasket

M5×20 hex

* The screws and gaskets are also available in G03174 - KR diaphragm X8.

Prerequisite

Grill disassembled.

See

(p.70).

Exploded view

For safety reasons, always use the new screws and spare parts provided in the KR.

Gradually tighten the screws following a star pattern.

If the speaker gasket is damaged, remove and replace it.

x4

3 N.m

4 mm

What to do next

(p.33) procedures.

X8 owner's manual (EN) version 1.0

71