9

Forestière

SECTION FOR USERS

Reloading. De-ashing

Position the air control lever at level “4”, to revive the fire. After several minutes, de-ash

and then reload.

To reload with coal, open the loading hatch on the top part. Fill to the upper level on the

front firebox plate: do not level out or pack down the coal, on the contrary, always leave

space above the ashes, either at the front or at the back of the firebox.

To reload with wood, open the firebox door and insert logs one by one.

After reloading, close the loading hatch (or firebox door) and do not forget to return the

air control lever to its initial setting as soon as the fire is firmly revived.

Insert the hook of the tool supplied with the appliance into the hole in the de-ashing pull

knob.

Push and pull alternately 6 to 8 times one after the other to shake the grate. De-ashing has

been done correctly if, when opening the ash pan door, you clearly see the glimmer from

the firebox reflected in the ash pan. Push the pull knob back before closing the outer steel

door.

De-ash at least twice a day and in particular when reviving the fire after overnight bur-

ning.

Empty the ash pan when it is two thirds full.

(Allowing ash to accumulate in the ash pan carries the risk of irreparable damage to the

firebox grate).

Close the ash pan door firmly.

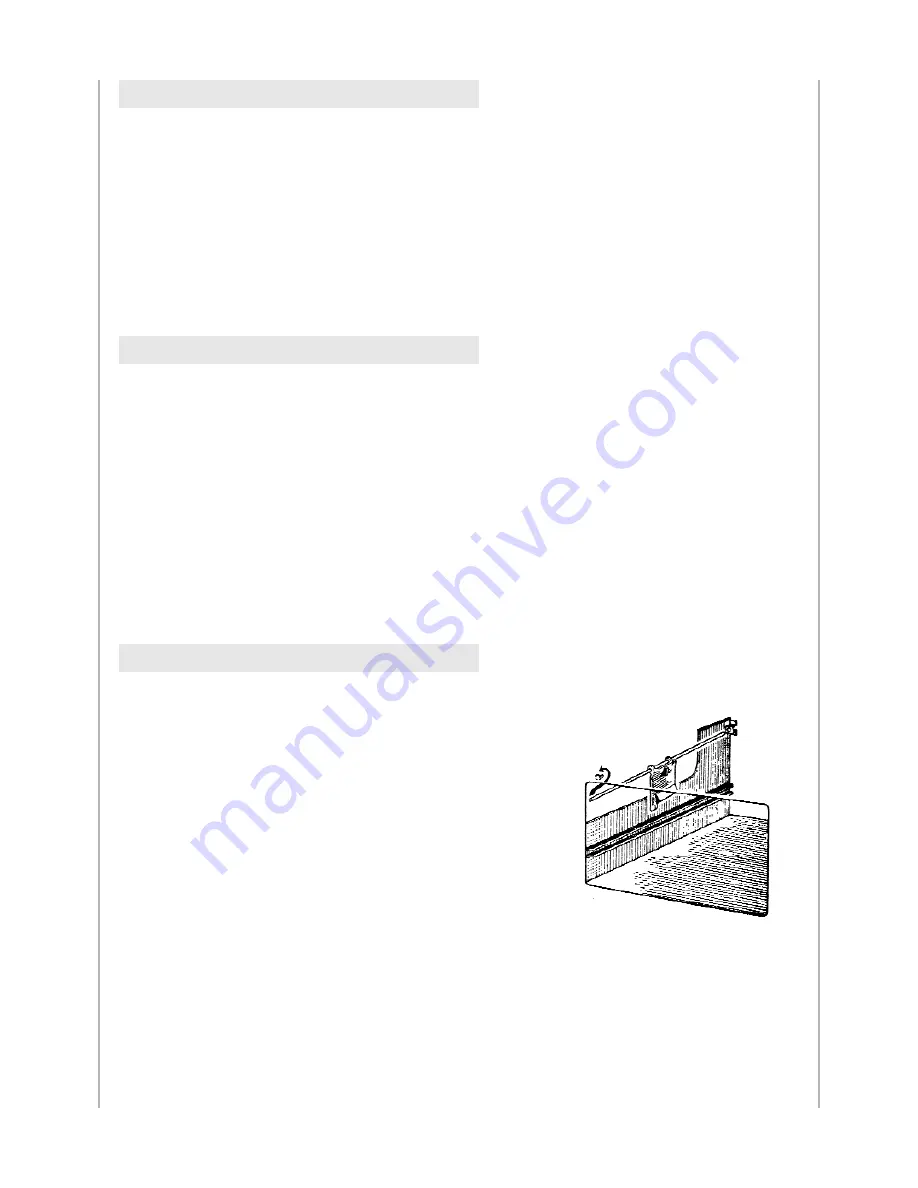

FITTING THE GUARD

Take the whole thing in two hands, the right hand on

the rounded iron axis and the left supporting the flap.

Insert this into the opening on the left-hand side of the

oven such that the lower lip of the flap is found on the

outside (of the oven side). Insert the axis into the rear

bearing located at the top left of the oven, turn to the

left and position the axis on the front in the groove pro-

vided for this purpose. Ensure the flap slides well. To do

this, move it forwards and backwards using the protru-

ding guide at the top.

USE OF THE GUARD

When you want a very hot oven (to sear a food for example), you must release the cent-

re of the oven side fully, in other words push the guard flap towards the back of the oven.

To cook over a gentle heat, do the reverse, in other words, slide the flap until it is in the

middle of the oven.

This is easy to do using the guide protruding at the top section of the guard.

7. R

ELOADING

8. D

E

-

ASHING

9. U

SING THE OVEN