4

1.2

Electrical Connections

Before beginning installation of electrical connections, ensure that all sources (AC & DC) are de-energized; verify

that no voltage is present on the field wiring by using a voltmeter. Check that the source voltage and frequency

match the

charger’s

specifications. Select field wire size using Table 1 below.

Wire terminal table

AC Input Terminal

Line-1, GND, N/L2

DC Output Terminal

Pos & Neg

Remote Temperature

Probe

+ + & - -

Minimum

Recommended

Wire Size *

18Ga

14Ga

Optional accessory supplied

by La Marche. Temp probe

includes correct wire size,

pre-crimped ferrules, and is

marked (+ + & - -)

Range of wire sizes

which fit the LMESpro

push-in spring terminals

18ga

→

14Ga stripped

18ga

→

14Ga w/ferrule

14Ga

→

8Ga stripped

14Ga

→

10Ga w/ferrule

Wire Strip Length

(Inch”/mm)

0.4” / 10mm

0.6” / 15mm

Table 1

–

AC/DC & Ground Wire Size Minimum Requirements

(All wires specified in the table are copper rated at 90 °C or 194 °F)

*

NOTE:

These are minimum recommended sizes per La Marche Standards. The National Electrical Code (NEC)

and Local Wiring Codes must be followed.

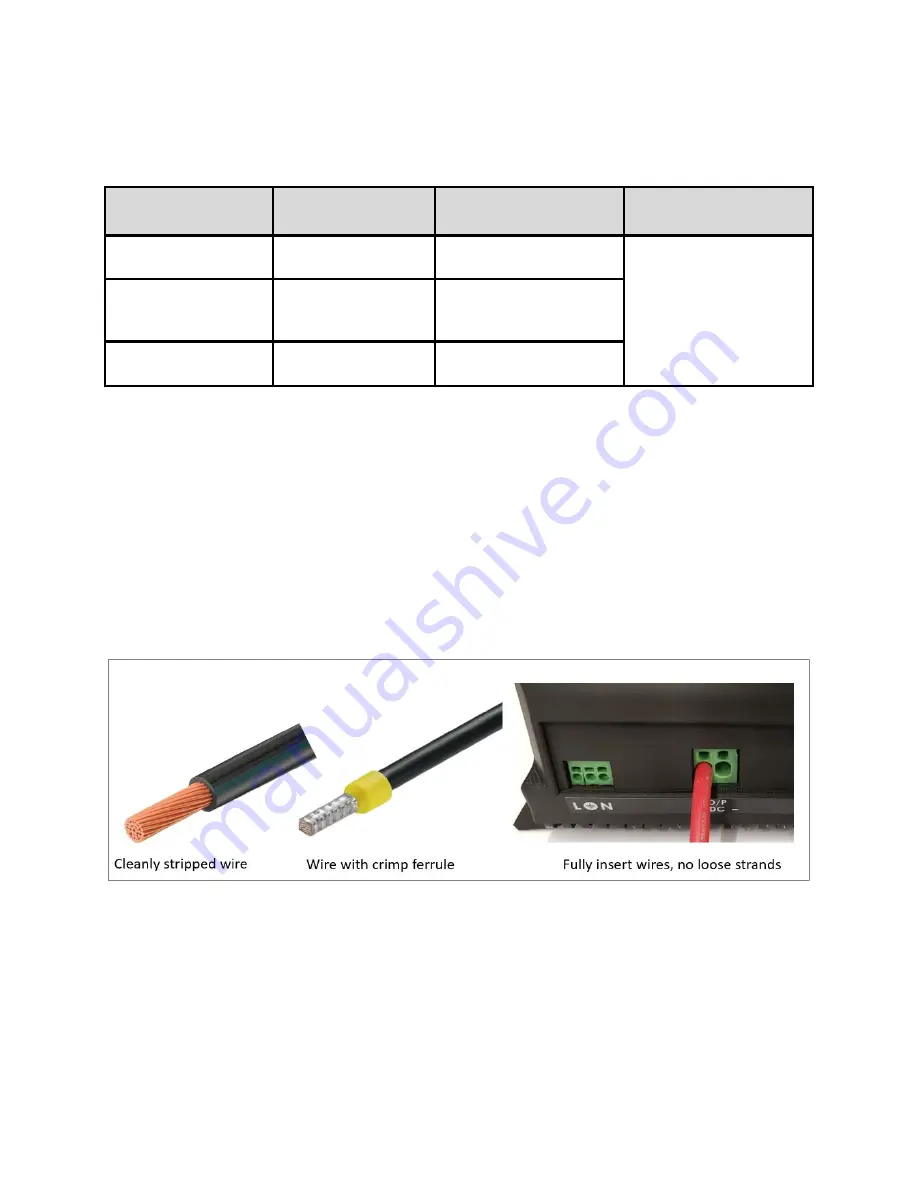

The LMESpro utilizes spring-loaded push-in style connectors. It is recommended to use wire crimp ferrules on

the AC & DC field wiring when installing the charger, however it is not absolutely necessary. Crimp ferrules will

prevent wire strands from fraying near the connectors. Being spring-loaded, the connectors are highly resistant

to vibration and do not require periodic torque checks as with a screw-terminal. See Figure-2.

To connect field wiring, you can simply push in the prepared conductors until fully seated. To make the wires

easy to push-in, you may insert a small flat-head screwdriver tip into the rectangular opening above the wire

entry to relieve spring-tension on the wire connection.

Figure 3 - Wire installation

To remove a wire connection (on a completely de-energized system AC & DC), insert a small screwdriver tip in

the rectangular opening above the wire to release spring pressure, then pull the wire out. See Figure 3.