FOCOLARI in ghisa

6097000 – EN

25

•

the construction materials of the involved products are not homogeneous, in fact there are simultaneously

parts in cast iron, steel, refractory material and majolica;

•

the temperature to which the body of the product is subject is not homogeneous: from area to area, variable

temperatures within the range of 300°C - 500°C are detected;

•

during its life, the product is subject to alternated lighting and extinguishing cycles in the same day, as well as

to cycles of intense use or of absolute standstill when season changes;

•

the new appliance, before being considered seasoned has to be subject to many start cycles to allow all

materials and paints to complete the various elastic stresses;

•

in detail, initially it is possible to remark the emission of smells typical of metals subject to great thermal

stress, as well as of wet paint. This paint, although during the manufacture it is backed at 250 °C fo r some

hours, must exceed many times and for a given period of time the temperature of 350 °C before becoming

completely embedded in the metallic surfaces.

Therefore, it is extremely relevant to take these easy steps during the lighting:

1.

Make sure that a strong air change is assured in the room where the appliance is installed.

2.

During the first starts, do not load excessively the combustion chamber (about half the quantity indicated in

the instructions manual) and keep the product continuously ON for at least 6-10 hours with the registers less

open than the value indicated in the instructions manual.

3.

Repeat this operation for at least 4-5 or more times, according to your possibilities.

4.

Then load more and more fuel (following in any case the provisions contained in the installation booklet

concerning maximum load) and, if possible, keep the lighting periods long avoiding, at least in this initial

phase, short ON/OFF cycles.

5.

During the first starts, no object should be leaned on the appliance and in detail on enameled surfaces.

Enameled surfaces must not be touched during heating.

6.

Once the «break-in» has been completed, it is possible to use the product as the motor of a car, avoiding

abrupt heating with excessive loads.

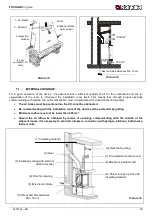

After testing the proper working of the appliance, some days from the installation, it is possible to proceed

with the construction of its aesthetic covering

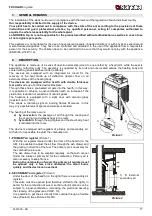

11. NORMAL OPERATION

After having positioned the registers correctly, insert the indicated hourly wood load (see CHAP. 17) avoiding

overloads that cause anomalous stresses and deformations. You should always use the FOCOLARE with the

door closed in order to avoid damages due to overheating (forge effect).

The inobservance of this rule makes the warranty expire.

With the registers located on the front of the device, it is possible to adjust the heat emission of the same. They have

to be opened according to the calorific need.

The best combustion (with minimum emissions) is reached when, by loading the wood, most part of the air for

combustion flows through the secondary air register.

The adjustment of the registers necessary to reach the rated calorific yield with a depression at the stack of 14 Pa

(=1.4 mm of column of water) is the following one:

Fuel

Primary air

Secondary air

Focolare PIANO

Wood

Closed

Open

Focolare TONDO

Wood

Closed

Open

Focolare PRISMA

Wood

Closed

Open

Besides the adjustment of the air for the combustion, the intensity of the combustion and consequently the thermal

performance of the device is influenced by the stack. A good draught of the stack requires a stricter adjustment of air

for combustion, while a poor draught requires a more precise adjustment of air for combustion.

To verify the good combustion, check whether the smoke coming out from the stack is transparent.

If it is white, it means that the device is not properly adjusted or the wood is too wet; if instead the smoke is gray or

black, it signals that the combustion is not complete (it is necessary a greater quantity of secondary air).

12. OPERATION DURING TRANSITION PERIODS

With an external temperature around about 15°C or w ith bad weather, and with a reduced thermal performance, the

stack intake may be damaged. The exhaust gases do not come out completely (intense smell of gas). In this case,

shake the grating more frequently and increase the air for the combustion. Then, load a reduced quantity of fuel.

Then, check that all openings for the cleaning and the connections to the stack are air-tight.