Installation

-

Programming_Sectional doors_Intellidrive 400_N°7132

This document is the exclusive property of FTFM La Toulousaine and must on no account be copied. The document may be modified at any time in accordance with product changes.

06/19

p.17

+

"Blocking" automatic mode

(mounted automatic then during a passage the timeout is reduced)

Recommended for opening by road tube, magnetic loop or cells

This programming can only be achieved after mandatory connection

of 2 sets of cells (Standard EN 13241

-

1).

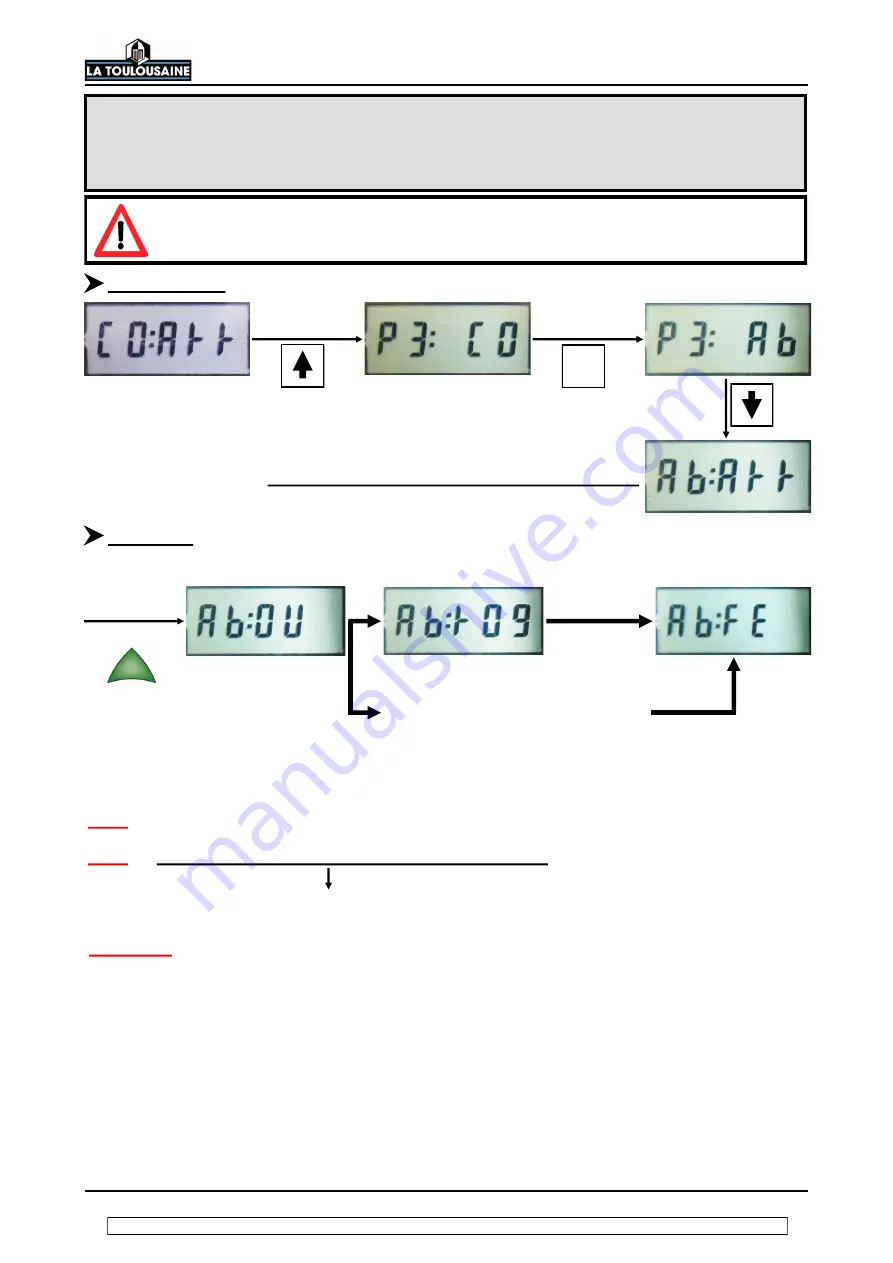

Programming :

Door closed

Press x3

Press x5

Press x3

"Blocking" automatic mode is programmed

Opening :

Operation :

Timeout

Door open

Automatic

closing

Passage or

press x1

Note :

Same as "Auto" automatic mode.

Timeout is taken back to 3 seconds before closing

Note² :

*If cells interruption during opening or timeout

If passage in front of the cells

Important :

If screen display an error, see chapter : Operation errors.

Summary of Contents for Intellidrive 400

Page 32: ......