24

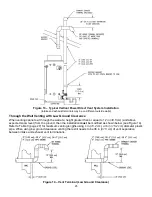

Figure 12

– Typical Horizontal Power Direct Vent System

Vertical Installation

Vertical venting system

must

be supported every 5 ft

(1.5 m)

of vertical run and every 3 ft

(.92 m)

of horizontal

run of vent pipe length.

CAUTION

Failure to properly support the vent piping with hangers and clamps may result in damage to the water

heater or venting system.

Stress levels in the pipe and fittings can be significantly increased by improper installation. If rigid pipe clamps

are used to hold the pipe in place or if the pipe cannot move freely through a wall penetration, the pipe may be

directly stressed, or high thermal stresses may be formed when the pipe heats up and expands. Install

accordingly to minimize such stresses.

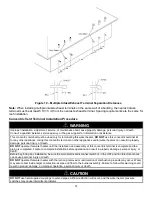

Follow the following procedure for direct venting through the roof:

1. Cut the necessary holes through the roof and ceiling. Cut two 4 ½ in

(11.4 cm)

diameter holes for 4 in

(

10.2 cm

) diameter pipe, two 3 ½ in

(8.9 cm)

diameter holes for 3 in

(7.6 cm)

diameter pipe,

or 6 5/8 in

(

16.9 cm

) diameter holes for 6 in (

15.2 cm

) diameter pipe in the ceiling and roof.

2. Install the exhaust vent and air intake plastic pipes as shown in Figure 13. Make sure that the installation

meets the local codes and/or The National Fuel Gas Code ANSI Z223.1 (Latest Edition) or CGA/CAN

B149 Installation Code.

Summary of Contents for LUHE120T

Page 42: ...42 BMS Wiring Diagram...

Page 44: ...44 Lighting and Shutdown Instructions Figure 31 Lighting Instruction Label...

Page 62: ......

Page 63: ......