MagnaTherm Boilers and Water Heaters

Page 13

Other methods of introducing combustion and

ventilation air are acceptable, providing they conform

to the requirements in the applicable codes listed

above.

In Canada, consult local building and safety codes

or, in absence of such requirements, follow CAN/

CSA B149.

3.C.1 Ducted Combustion Air

The combustion air can be taken through the

wall, or through the roof. The manufacturer offers

accessories to use with ducted air systems, as

shown in Table 6.

See Table 7 to select the appropriate diameter air

pipe. When taken from the roof, a field-supplied

rain cap or an elbow arrangement must be used to

prevent entry of rain water. (See Figure 8).

Use ABS, PVC, CPVC, polypropylene, stainless

steel, or galvanized pipe for the combustion air

intake (See Table 7). The intake must be sized per

Table 3. Route the intake to the boiler as directly

as possible. Seal all joints. Provide adequate

hangers. The unit must not support the weight of the

combustion air intake pipe. The maximum equivalent

pipe length allowed is 100 feet (30 m).

Each elbow is considered to be 5 feet (1.5m)

When using polypropylene or stainless steel

materials in horizontal duct configurations, a single

elbow must be installed on the end of the air inlet

to act as an outdoor terminal. In vertical duct

applications, two elbows must be installed on the

end of the inlet to act as a vent terminal. When

elbows are use as terminals, appropriate screens

must be installed to prevent blockage.

The elbow(s) required for termination are not

included in the kits sown in Table 6

The connection for the intake air pipe is on the back

panel.

In addition to air needed for

combustion, air shall also

be supplied for ventilation,

including air required for

comfort and proper working

conditions for personnel.

Refer to the applicable

codes.

3.D Venting

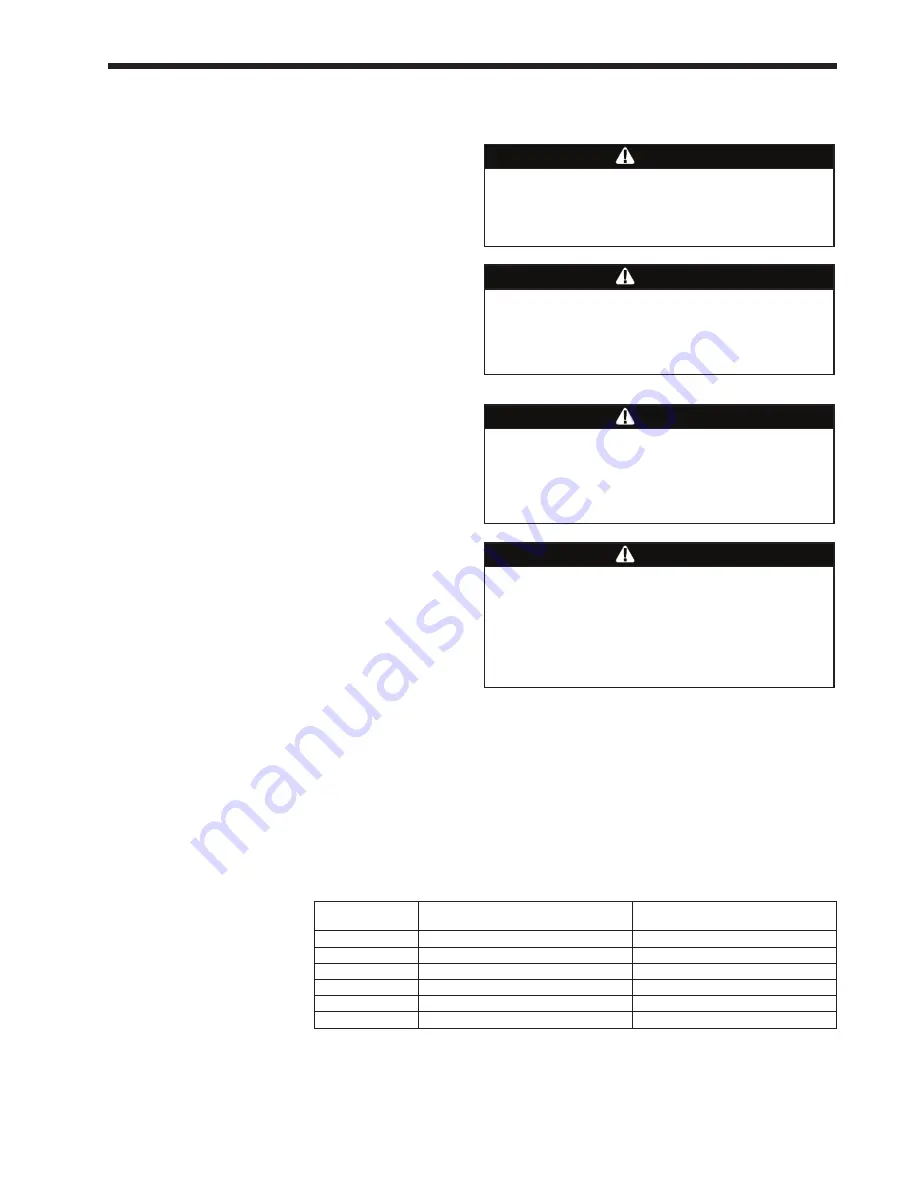

WARNING

Selection of improper vent materials for

installations that are installed in closets, or will be

operated in high ambient temperature levels, may

lead to property damage, personal injury, or death.

WARNING

Failure to use the appropriate vent material,

installation techniques, or glues and sealants

could lead to vent failure causing property

damage, personal injury or death.

WARNING

Use of cellular core PVC (ASTM F891), cellular

core CPVC, or Radel® (polyphenolsulfone) in

non-metallic venting systems is prohibited and that

covering non-metallic vent pipe and fittings with

thermal insulation is prohibited.

WARNING

All venting must be installed according to this

manual and any other applicable local codes,

including but not limited to, ANSI Z223.1/NFPA 54,

CSA B149.1, CSAB149.2 and ULC S636. Failure

to follow this manual and applicable codes may

lead to property damage, severe injury, or death.

If the system temperatures are unknown at the

time of installation, class IIC or higher venting

material is recommended.

This unit is a Category II and IV appliance and

may be installed with vent materials meeting the

standards listed on Table 10.

The units vent can terminate through the roof, or

through an outside wall.

Table 8. Vent Sizing for Category II - Gravity Vent

Table 2 – Vent Sizing for Category II – gravity vent

Boiler Model

Vent Connection Size Diameter

(provided with boiler)

Vent Connector Size Diameter

(Increaser*)

MGH/V1600

6”

14”

MGH/V2000

8”

14”

MGH/V2500

8”

18”

MGH/V3000

10”

18”

MGH/V3500

10”

22”

MGH/V4000

12

22”

WARNING

: Vent must be installed with appropriate condensate traps and using only specific

manufacturers, models and materials outlined in this manual.

Draft must always remain between -0.1” and -0.001” at all firing rates. If pressures outside of

this range are measured, consult professional venting engineer for recommendations, such as

double-acting barometric dampers to avoid reduced performance or hazardous conditions.