LAARS Heating Systems

Page 10

If the system temperatures are unknown at the

time of installation, class IIC or higher venting

material is recommended.

The MagnaTherm is a category iV appliance and

may be installed with the standards listed on Table 6.

The unit’s vent can terminate through the roof, or

through an outside wall.

All installations must be done following the vent

supplier’s recommended installation techniques.

if these are not available, refer to the Laars

recommendations for the material used.

For category iV boilers, have horizontal runs

sloping upwards not less than 1/4 inch per foot

(21 mm/m) from the boiler to the vent terminal;

be installed so as to prevent accumulation of

condensate; and, where necessary, have means

provided for drainage of condensate.

Pour la catégorie iV, les chaudières ont horizontal

en pente vers le haut au moins 1/4 de pouce par pied

(21 mm/m) à partir de la chaudière pour l’évent

borne; être installé de façon à éviter l’accumulation

de condensats; et, le cas échéant, ont des moyens

prévus pour l’évacuation des condensats.

This will allow the condensate to run back to the

MagnaTherm to drain. Route the vent pipe to the

heater as directly as possible. Seal all joints. Provide

adequate hangers as required in the venting system

manufacturer’s installation instructions, or at least

every 4 feet.

The unit must not support the weight of the vent

pipe. The maximum equivalent pipe length allowed

is 100 feet (30m). Each elbow is considered to be

5 feet (1.5m). Laars offers accessories to use with

horizontal and vertical exhaust vent systems, as

shown in Table 5

3.2.1

Common Venting

common venting is explicitly not allowed without

the addition of an external vent extraction fan,

professionally engineered and approved by the local

jurisdiction. MagnTherm units are never permitted

to share a vent with any catagory 1 appliances.

3.2.3

Venting requirements Unique to

Canada

MagnaTherm boilers and water heaters are Vent

table 5. Vent accessories

(Place in section 3.1)

Model 2000

Model 3000

Model 4000

Screen for horizontal galvanized air pipe

D2012101

D2012102

D2012103

Screen for horizontal PVC air pipe

CA012001

CA012002

CA012003

Screen for horizontal polypropylene air pipe

CA012201

CA012202

CA012203

Screen for vertical galvanized air pipe

D2012201

D2012202

D2012203

Screen for vertical PVC air pipe

CA012401

CA012402

CA012403

Screen for vertical polypropylene air pipe

CA012601

CA012602

CA012603

Table 3a - Ducted Air Accessories

(Place in section 3.2)

Model 2000

Model 3000

Model 4000

Horizontal vent terminal for stainless steel

D2012001

D2012002

D2012003

Screen for horizontal CPVC vent

CA012101

CA012102

CA012103

Screen for vertical stainless steel vent

D2012301

D2012302

D2012303

Screen for vertical CPVC vent

CA012501

CA012502

CA012503

Table 3* - Vent Accessories

(Place in section 3.5)

Model 2000

Model 3000

Model 4000

Air intake screen for unit placed outdoors

CA011901

CA011902

CA0011903

Vent terminal for unit placed outdoors

CA011801

CA011802

CA011803

Table 3** - Air & Vent Accessories for Units Placed Outdoors

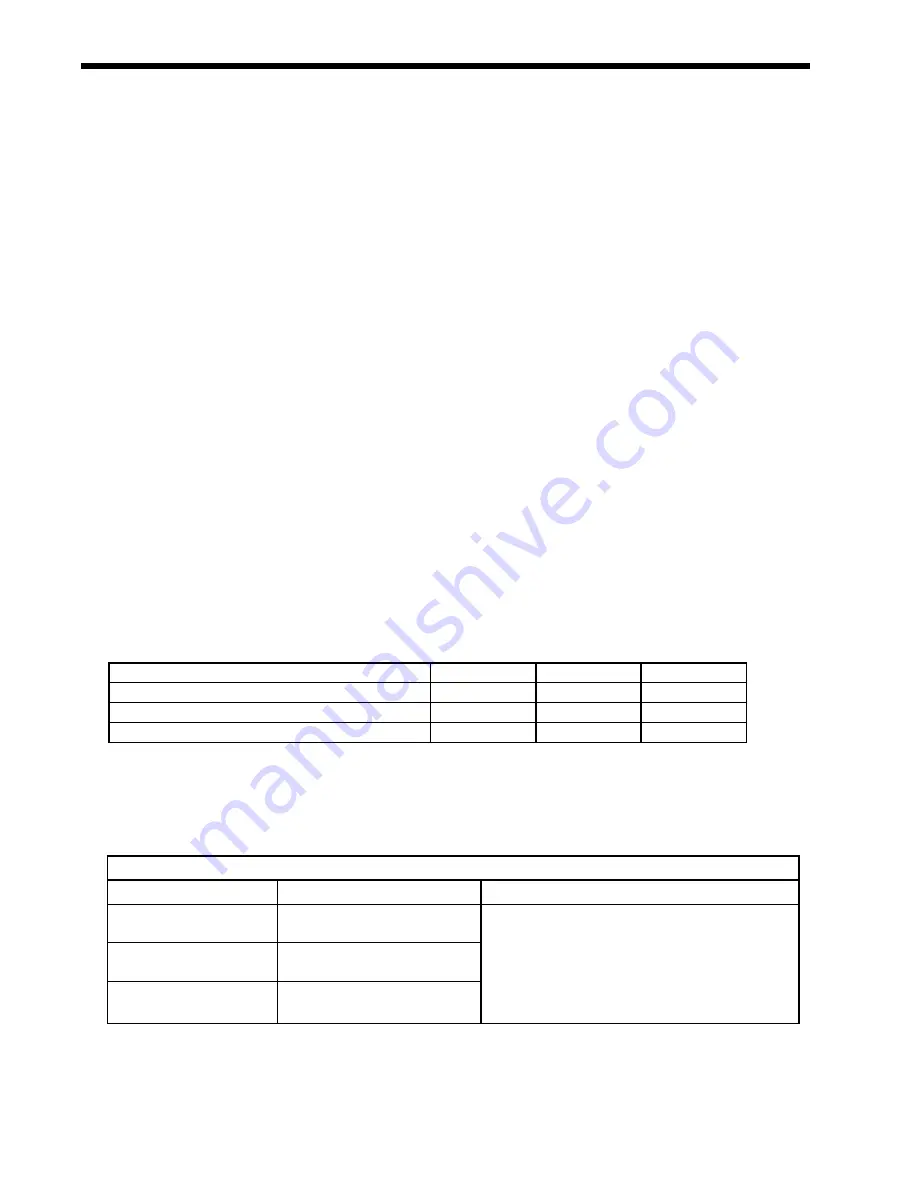

Installation Standards

Material

United States

Canada

Stainless steel

UL 1738

Venting must be ULC S636 certified for use as

venting material. The venting material class must

be chosen based upon the intended application

of the boiler, and must be installed according to

the maximum flue gas temperature and the vent

manufacturer’s instructions.

CPVC, sch 40

ANSI/ASTM F441

Polypropylene

Pending aPProVal

ULC S636 Class 2C

table 6. required exhaust Vent material