20 Industrial Way, Rochester, NH 03867

•

603.335.6300 • Fax 603.335.3355

1355 Kuehner Drive, Simi Valley, CA 93063

•

800.900.9276

•

Fax 800.559.1583

(Sales, Service)

480 S. Service Rd. West, Oakville, Ontario, Canada L6K 2H4

•

905.844.8233

•

Fax 905.844.2635

www.Laars.com

Litho in U.S.A. © Laars Heating Systems 0603

Doc. H2318800

LP Conversion for Mascot HT 3.30 & HT 1.33 / HT 1.450 & HT 1.650

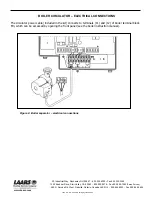

The following operations must be performed before calibrating the gas valve.

1. For

the

HT 3.30 & HT 1.330 turn the adjuster screw (V) (2.5mm hex) on the gas valve clockwise four

complete revolutions. For the HT 1.450,turn the adjuster screw three complete revolutions, and for

the HT 1.650, five complete revolutions.

2. On the QAA73 remote control, remove the back cover and connect two field supplied thermostat wires to the

black terminal block. These wires are then connected to terminals 4 and 5 of the boiler terminal strip (inside

control compartment). For HT 3.30 & HT 1.330 set parameters 608 to 35% and parameter 611 to

3700 rpm. For HT 1.450, leave parameter 608 at 25% and set parameter 611 to 2100 rpm. For HT

1.650, leave parameter 608 at 24% and set parameter 611 to 2000 rpm.

TO SET PARAMETERS:

The editable parameters are those between 504 and 652. Proceed as follows to access these parameters.

1. Simultaneously press keys 1 and 4 on the QAA73 remote control for about 3 seconds. The message

“Initializing BMU parameters” appears on the display.

2. Simultaneously press keys 1 and 2 for about 3 seconds. The message “Initializing BMU Service” appears on

the display.

3. Press keys 1 or 2 to scroll through the list of parameters.

4. To change the value of a selected parameter, press key 3 or 4 to decrease or increase the value respectively.

5. Press key 5 to enter the new values and exit programming of the boiler.

K

P out

V

Pl

P

Pi

QAA73

Back Cover

Terminal Strip