Page 6

LAARS HEATING SYSTEMS

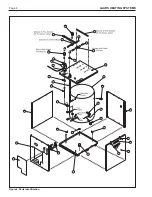

Figure 6. Wiring Diagram.

WARNING

Electrical shock can cause severe personal injury or

death. Disconnect power supply to the boiler before

doing any electrical work.

Electrical Connection (see Figures 5 and 6).

1.

Remove the two screws attaching the front cover

of the control box.

2.

There are six wires coiled in the area on the right

side of the control box, supplied with wire nuts:

2 black wires twisted together, 3 white wires

twisted together, and a brown wire.

3.

Follow the schematics in Figures 5 and 6.

Remove the wire nut from the two black wires,

and connect the hot lead from a 115 volt power

supply to both wires. Secure the three wires in

the wire nut.

4.

The three white, neutral wires should be joined

to the other neutral lead coming from the 115

volt power supply, and the neutral lead coming

from the pump (space heating).

5.

The brown wire attaches to the hot side of the

space heating pump.

H2021000A

BK

-

BLACK

W

-

WHITE

R

-

RED

Y

-

YELLOW

BL

-

BLUE

BR

-

BROWN

O

-

ORANGE

P

-

PURPLE

G

-

GREEN

BL/Y -

BLUE/YELLOW STRIPE

BR/Y -

BROWN/YELLOW STRIPE

115V-FACTORY WIRED

115V-FIELD WIRED

24V-FACTORY WIRED

24V-FIELD WIRED

IF ANY OF THE ORIGINAL WIRE (AS

SUPPLIED WITH THE APPLIANCE) MUST

BE REPLACED, IT MUST BE REPLACED

WITH APPLIANCE WIRING MATERIAL

SUITABLE FOR 105 DEGREES C OR ITS

EQUIVALENT

HOT

TANK

AQUASTAT

BR

WALL

THERMOSTAT

(FIELD

SUPPLIED)

P

24V

COM

SEN

NC

NO

COM

TRANSFORMER

BK

24V

115V

R

Y

Y

G

W

ZONE

PUMP

RELAY

GROUNDING

CONDUCTOR

NEUTRAL

115/60HZ

POWER SUPPLY

BK

BK

BR

PUMP

(FIELD

SUPPLIED)

W

TANK

PUMP

BR

TANK

PUMP

RELAY

INDUCER

BL

Y

INDUCER

MOTOR

RELAY

BR

O

P

Y

GAS VALVE

MOLEX

BL

R

R

P

Y

Y

PRESSURE

SWITCH

ROLL-OUT

SAFETY

SWITCH

BL

P

O

R

HIGH

LIMIT

AQUASTAT

(OPTIONAL)

SENSOR

R

BL

R

W

R

R

W

A

TERMINAL

STRIP

R

R

R

1

4

3

2

6

5

R

1

4

3

2

6

5

R

1

4

3

2

6

5

MODEL MCH

BK

Y

W

4.

When water discharges from the faucet,

close it. Check for system leaks and repair

if necessary.

•

Filling and connecting boiler pipes:

Consult the JV boiler manual, Document 1080.

Caution

Never use water heater/boiler unless it is

completely filled with water.

2D. Wiring

Priority System: Under this wiring the storage

tank will be supplied before space heating. This will

insure that it gets adequate hot water flow from the

boiler to maintain a fully rated delivery of domestic

hot water.

Caution

In this priority mode, any demand for space heating

is postponed until the storage water tank has

reached set temperature. This delay in supplying

the space heating zones is usually not noticed by

the inhabitants of the living spaces. However, in the

event of certain storage water tank malfunctions,

space heating could be delayed indefinitely. If

undetected and un-corrected, freezing damage to

piping could result.