LAARS Heating Systems

Page 36

Customer Service and Product Support:

800.900.9276 • Fax 800.559.1583

Headquarters:

20

Industrial Way, Rochester, NH 03867 • 603.335.6300 • Fax 603.335.3355

1869 Sismet Road, Mississauga, Ontario, Canada L4W 1W8 • 905.238.0100 • Fax 905.366.0130

www.Laars.com

Litho in U.S.A. © Laars Heating Systems 1607 Document 4290A

800.900.9276

•

Fax 800.559.1583

(Customer Service, Service Advisors)

20 Industrial Way, Rochester, NH 03867

•

603.335.6300

•

Fax 603.335.3355

(Applications Engineering)

1869 Sismet Road, Mississauga, Ontario, Canada L4W 1W8

•

905.238.0100

•

Fax 905.366.0130

www.Laars.com

Document 4290A

M

ascot FT Floor-Standing Gas Conversion Kit

pg 3 of 4

Manifold pressure

‘NG’ type combustibility

‘LP’ type combustibility

2" VENT

3" VENT

2" VENT

3" VENT

MFTCF140

MAX Fire

-0.15

"

WC

-0.216

"

WC

-0.15

"

WC

-0.216

"

WC

MIN Fire

0

”

WC

0.002

”

WC

0.1

”

WC

0.079

”

WC

MFTCF199

MAX Fire

-0.134

”

WC

-0.173

”

WC

MIN Fire

-0.015

”

WC

-0.015

”

WC

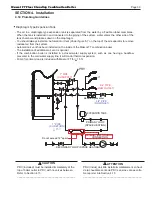

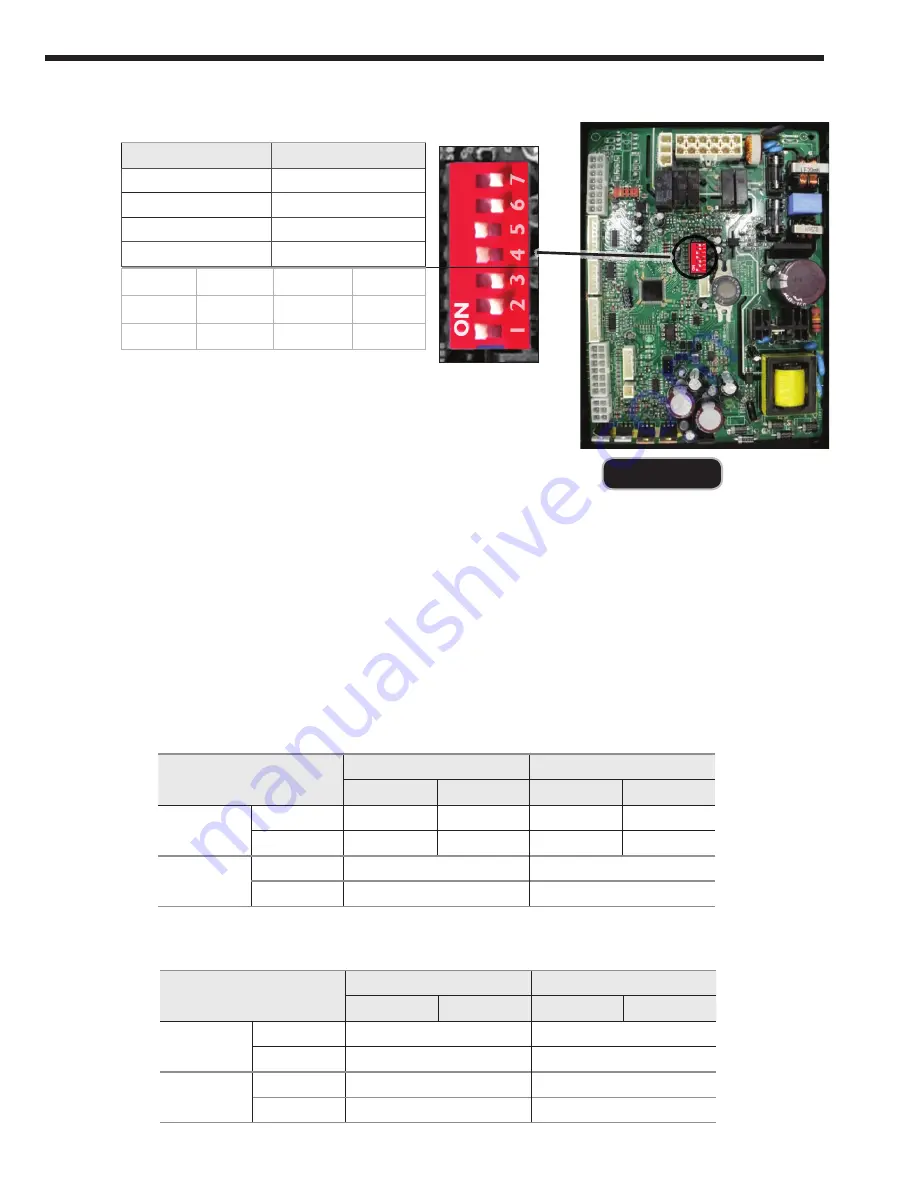

Figure D

15.

Setup your combustion analyser and place the sensor

into the combustion test port

16.

Per

Table B for Max Fire

,

change dip switch 6 to ON and 7 to OFF.

The unit will cycle up to MAX fi re.

17.

WAIT for your combustion analyser to stabilize. This may take up to 3 minutes depending on your combustion

analyser. Then check the CO2

measurement for MAX fi re. Refer to Table D for acceptable MAX fi re

combustion readings. At this point, just record the CO2 readings at MAX Fire.

Do NOT attempt to adjust

CO2 at MAX Fire. ONLY in MIN Fire, so...

18.

Per

Table B for MIN Fire

,

change dip switch 6 to OFF and 7 to ON. The unit will cycle down to MIN Fire.

19.

WAIT for your combustion analyser to stabilize. Then check the CO2

measurement at MIN fi re. Refer to

Table D for acceptable MIN fi re combustion readings.

20.

If CO2

readings in Max Fire and MIN fi re are acceptable, then skip ahead to Step 23. If not, then open the

Gas Valve Adjustment Port by removing the cap screw with a 4mm Allen wrench. See Figure E.

21.

Then use the 4 mm Allen wrench to make a minor adjustment (1/8 turn) to either increase or decrease CO2.

Table B

DIP Switch Settings

MBH N/A 140 N/A 199

ON

OFF

MIN

Fire

Normal Operation

MAX

Fire

Normal Operation

NG Natural

LP Propane

3” Vent Size

2” Vent Size

ON

OFF

ON

ON

ON

OFF

OFF

ON

OFF

ON

ON

ON

DO

N

OT

C H

A N

G E

REFE

RENCE

ON

LY.

CO

2

value

‘NG’ type combustibility

‘LP’ type combustibility

2" VENT

3" VENT

2" VENT

3" VENT

MFTCF140

MAX Fire

8.5~10.5%

9.5~11 %

MIN Fire

8~10%

9~10.5 %

MFTCF199

MAX Fire

8.5~10.0%

9.5~11 %

MIN Fire

8~10%

9~10.5 %

Table C

Table D

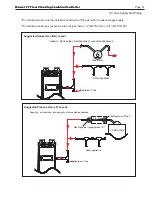

4.13 Natural Gas to Propane Conversion

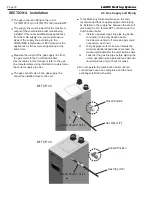

SECTION 4. Installation

Summary of Contents for MFTCF140

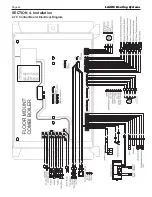

Page 48: ...LAARS Heating Systems Page 46 4 19 Control Board Electrical Diagram SECTION 4 Installation...

Page 65: ...Mascot FT Floor Standing Combination Boiler Page 63 6 2 Fault Tree Analysis 1 Flame detection...

Page 75: ...Mascot FT Floor Standing Combination Boiler Page 73...

Page 78: ...LAARS Heating Systems Page 76 Heat Exchanger MFTCF140...