LAARS Heating Systems

Page 14

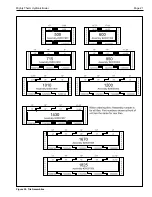

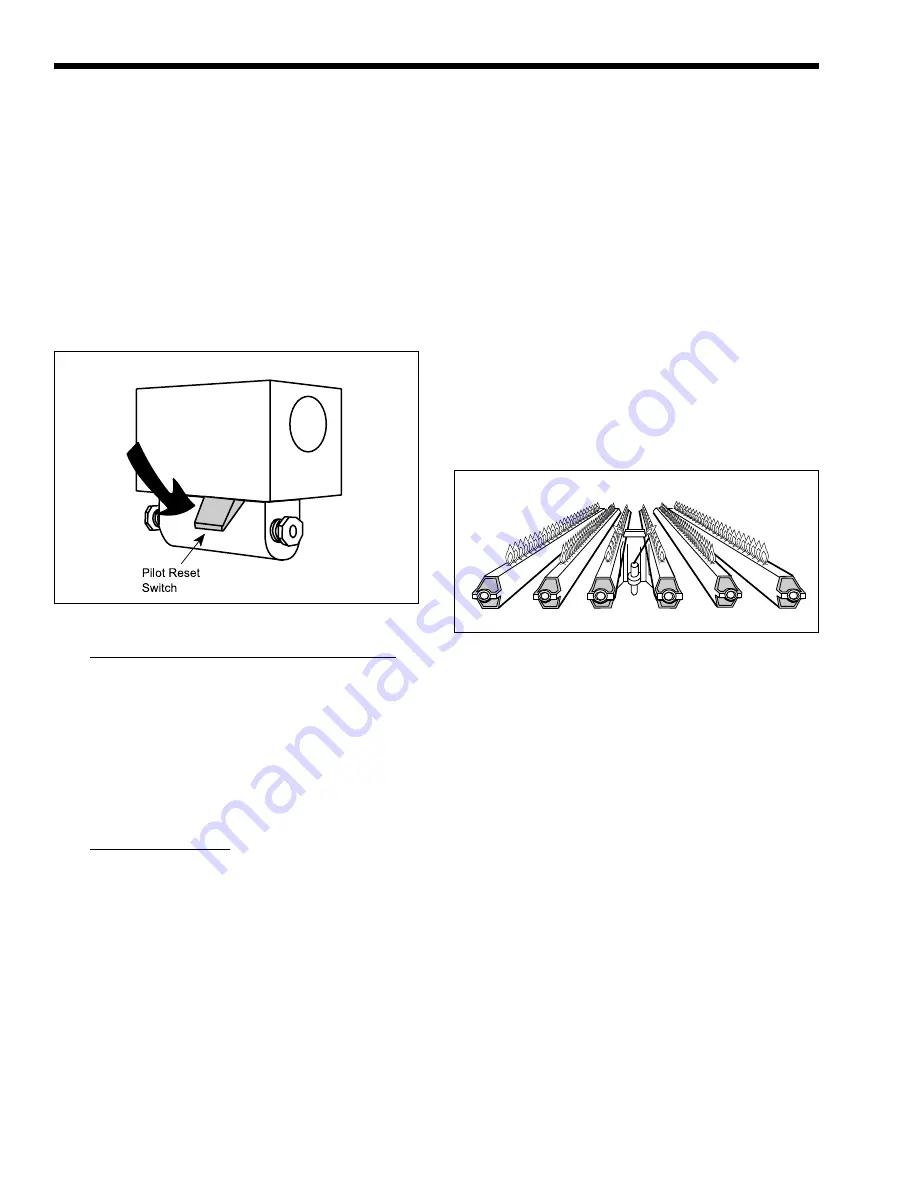

Figure 16. Main Burner Flame Pattern.

f.

Open manual pilot valve. Turn on main

electrical switch.

g.

Set temperature controller to desired

temperature. Pilot will light automatically

to ignite main burners whenever the

aquastat calls for heat.

h.

For standing pilot system, press on pilot

relay knob (see Figure 15), light pilot and

keep relay knob depressed for one minute

then release. Once the pilot is lit, the power

is supplied through the aquastat to the main

gas valve.

remove drain plug in the bottom of front header cover.

Drain every part of system subject to freezing

temperature.

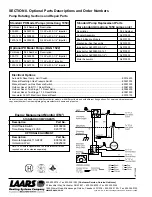

SECTION 4.

Maintenance

1.

Lubricate the water circulating pump (see

instructions found on the pump).

2.

If a strainer is employed in a pressure reducing

valve or in piping, clean it every six (6) months.

3.

At start-up and every six (6) months thereafter,

the pilot and main burner flame should be

observed for proper performance (see Figure 16).

See attached lighting and shut-down instructions

for proper pilot flame pattern). If flame has the

appearance of “sooting” tips, check for debris

near orifices. Call serviceperson.

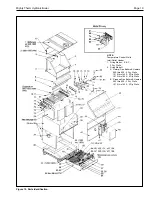

Figure 15. Pilot Safety Relay.

2.

To set the temperature and high-limit controls:

a.

Set the temperature controller at the system

design temperature.

b.

Set the high-limit to 40-50°F above

temperature controller setting.

c.

Models with Mechanical Modulation

Set the temperature controller (Modu-Snap

valve) dial to the desired water temperature

(see Table 5).

3.

Minimum input rates:

The low firing rate setting must be equal to or

greater than the specified minimum input rating

as shown on the appliance rating plate. Laars’

boilers use gas valves which are factory set to

provide an input on low fire that meet or exceed

the specified minimum.

3D. To Turn Off Boiler:

1.

Turn off main electric switch.

2.

Close all manual gas valves.

3E. To Shut Down System:

To shut down boiler, turn off all manual gas

valves and electrical disconnect switches. Whenever

danger of freezing exists, shut off water supply and

4.

Inspect the venting system for obstruction,

leakage and corrosion at least once each year.

5.

Keep boiler area clear and free from combustible

material, gasoline and other flammable vapors

and liquids (see Table 2 for minimum

clearances).

6.

Be certain all combustion air and ventilation

openings are unobstructed.

7.

Check for fouling on the external surfaces of the

heat exchanger every six months. (

NOTE

: After

installation and first start-up, check the heat

exchanger for fouling after the following periods

of operation: 24 hours, 7 days, 30 days, 90 days,

and once every six months thereafter).

Fouling on the external surfaces of the heat

exchanger is caused by incomplete combustion

and is a sign of combustion air and/or venting

problems. As soon as any fouling is observed,

the cause of the fouling should be corrected (see

Section 5, Troubleshooting Guide

). The heat

exchanger can be checked by locating a mirror

under the burners with a flashlight. An alternate

method is to remove the venting and top panel as

necessary to inspect from above. Also check the

vent system for defects at this time.