LAARS HEATING SYSTEMS

Page 8

Check heater wiring and pump for correct

voltage, frequency and phase. Consult the

National Electrical Code or the Canadian

Electrical Code regarding branch circuit

requirements for equipment with these motors.

2.

The heater should be wired exactly as shown in

the wiring diagram.

3.

All field installed electrical safety devices and all

field installed controllers (valve end switches,

draft switches, relays, timers) can be connected

to the heater control to the terminals shown in

the wiring diagram designated “Field Interlock.”

4.

Where the heater is installed with a draft fan

refer to the fan manufacturer's wiring diagram.

The draft switch should be wired across the field

interlock terminals in the heater control panel.

SECTION 3.

Water Piping Instruction

3.1 General Piping Practice

1.

Be sure to provide valves at the inlet and outlet

of the heater so it can be readily isolated for

service. A butterfly, ball type or similar type of

valve is recommended.

2.

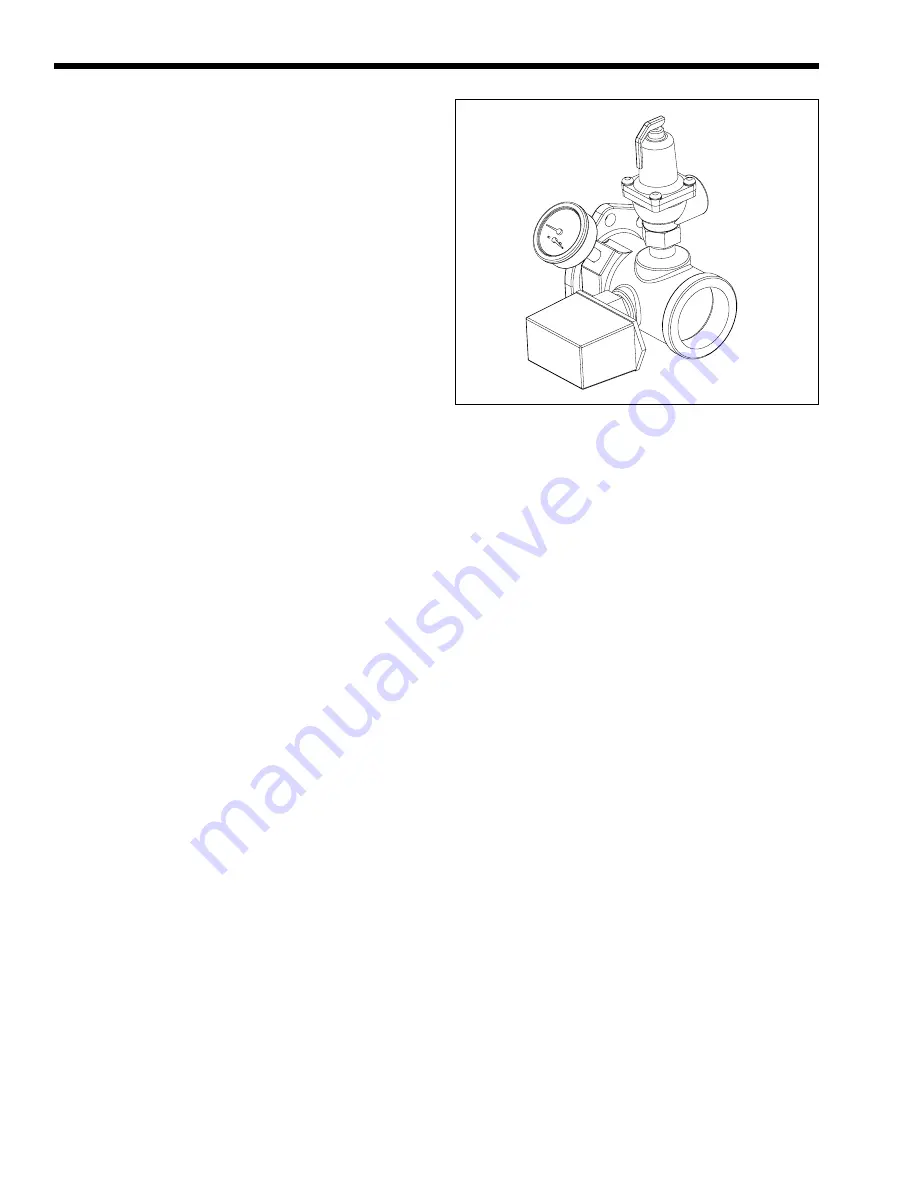

The pressure relief valve installed in the tapped

opening provided in the outlet header (see Figure

7), must be piped, but not fastened, to a drain or

floor sink. The drain pipe must be the same size

as the valve outlet and must pitch downward

from the valve. Pay special attention to relief

valve settings in installations where the heater is

located on the ground floor of a tall building, or

where the operating temperature of the heater is

above 210°F (99°C). In both instances, the static

pressure of the system is elevated and could

cause the relief valve to leak and bring

considerable raw water into the system.

3.

Where no special setting of the relief valve is

ordered, the factory will furnish a 75 psi setting

for heating boilers (PH models), and 125 psi for

water heaters (PW models).

4.

The pressure relief valve lever must be tripped at

least once a year to insure that waterways are

clean. When manually operating lever, water will

discharge through the drain line. Precautions

must be taken to avoid contact with hot water

and water damage.

3.2 Heating Boiler (PH Model)

3.2.1 Variable Water Flow System

Heating systems using zone valves, zone pumps

or 3-way valves can experience reduced water flow

Figure 7. Pressure Relief Valve Location.

through the boiler. This can result in an excessive

water temperature rise and unstable boiler operation. If

the system water flow is variable, the boiler's

temperature sensor must be installed in the outlet

water. Laars recommends primary-secondary pumping

for all variable flow systems (see Figure 9). Primary-

secondary pumping is mandatory for variable flow

systems. The boiler pump in a primary-secondary

system maintains constant flow through the boiler

even though the system flow is variable. In a primary-

secondary system the pressure drop of the boiler is not

added to the system.

3.2.2 System Pressure Requirements

The boilers are designed to operate on closed,

pressurized systems. Maintain a minimum of 12 psi

(81.8 kPa) on the system where boiler supply water

temperature is 200°F (93°C) or less. If higher

temperatures are required, the minimum system

pressure should be at least 15 psi (102.2 kPa) above

the water vapor pressure corresponding to the elevated

water temperature.

Heating boilers are not suitable for open systems

unless the supply water temperatures are kept below

180°F (82°C), and a minimum of 5 psi (34.1 kPa)

static head is maintained at the boiler.

3.2.3 Hot/Chilled Water Systems

When a boiler is connected to an air conditioning

system where the same water is used for heating and

cooling, you must prevent chilled water from entering

the boiler When changing such a system from cooling

to heating, allow the chilled water to circulate through

the building, after the chiller has been turned off, for a

period long enough for the water to warm up to at

least 105°F (41°C) before the water flows into the

boiler. It is equally important to prevent hot water

from entering the chiller. The system shown in