Mini-Combo II

Page 5

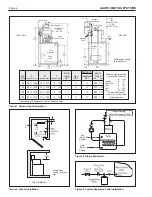

2C. Piping

•

To Prevent damage to the unit, all soldering is to

be done prior to assembling the cold and hot

water, and any other connections to the tank.

•

Use suitable pipe dope or tape.

•

Before piping the boiler to the heating system,

be sure to install the system check valve

(provided with the unit) onto the inlet (return)

tee of the boiler with arrow pointed downward

(see Figure 3).

•

If anti-freeze is used in boiler system, local codes

may require a backflow preventer on cold supply

line. Use anti-freeze specifically intended for

hydronic heating system. Inhibited propylene

glycol is recommended.

WARNING

Do not use automotive or ethylene glycol anti-

freeze, or any undiluted anti-freeze. This can cause

severe personal injury, death or substantial property

damage.

If a backflow preventer, pressure reducing valve

or check valve is in cold water supply, install an

expansion tank on cold water supply line (Figure 4) to

prevent normal thermal expansion from repeatedly

forcing open the T&P relief valve.

T&P relief valves discharge piping must be

directed so that hot water flows away from all persons.

Attach run-off tube to T&P valve and run tube within

6" (152mm) from floor. No reducing couplings,

valves, or any other type of restriction is to be

installed in this line. This run-off tube must be

installed to allow free and complete drainage of both

valve and run-off tube.

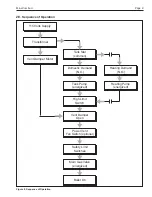

Filling Storage Water Tank

1.

Open hot water faucet in house to allow air in the

tank and in piping to escape.

2.

Open shut-off valve(s) in cold water supply line.

3.

Open shut-off valve(s) in hot water supply line.

4.

When water discharges from the faucet, close it.

Check for system leaks and repair if necessary.

Filling and connecting boiler pipes:

Consult the JV boiler manual, Document 1025.

Caution

Never use water heater/boiler unless it is

completely filled with water.

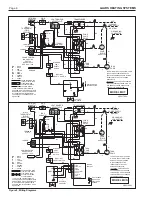

2D. Wiring

Priority System: Under this wiring the storage

tank will be supplied before space heating. This will

insure that it gets adequate hot water flow from the

boiler to maintain a fully rated delivery of domestic

hot water.

Caution

In this priority mode, any demand for space heating

is postponed until the storage water tank has

reached set temperature. This delay in supplying

the space heating zones is usually not noticed by

the inhabitants of the living spaces. However, in the

event of certain storage water tank malfunctions,

space heating could be delayed indefinitely. If

undetected and uncorrected, freezing damage to

piping could result.

WARNING

Electrical shock can cause severe personal injury

or death. Disconnect power supply to the boiler

before doing any electrical work.

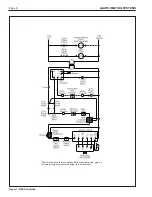

Electrical Connection: (See Figure 5, 6 and 7)

1.

Remove the two screws attaching the front cover

of the control box.

2.

There are five wires coiled in the area on the

right side of the control box, supplied with wire

nuts: 2 black wires twisted together, 2 white

wires twisted together, and a brown wire.

3.

Follow Figures 5, 6 and 7. Remove the wire nut

from the two black wires, and connect the hot

lead from a 115 volt power supply to both wires.

Secure the three wires with the wire nut.

4.

The two white, neutral wires should be joined to

the other neutral lead coming from the 115 volt

power supply, and the neutral lead coming from

the pump (space heating).

5.

The brown wire attaches to the hot side of the

space heating pump.

6.

There is a molex connector located on the left

side of the control panel. Connect the vent

damper harness to the molex connector and the

other end to the vent damper receptacle.

NOTE: The connection in step 6 should remain

intact at all times, otherwise the boiler will not fire.

Some Canadian units are supplied with vent

damper jumper plug. Do not remove jumper unless

vent damper is to be installed.