Page 23

SECTION 7

ELECTRICAL AND WIRING DIAGRAMS

Table 7. Boiler Electrical Data

Water Flow Requirements

Electrical

Data

All Sizes

with

Low Loss Header

without

Low Loss Header

Voltage

120 V

120 V

FLA

.70 A

.20 A

MCA

.9 A

.25 A

MOP

15 A

15 A

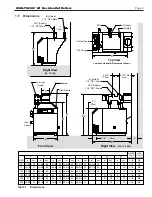

Minimum Clearances

Left + Right Sides

Front

Flue and Rear

Top

Size

inches

cm

inches

cm

inches

cm

inches

cm

ALL

4

10

2

5

6

15

20

51

Minimum

Clearances

from

Adjacent

Construction

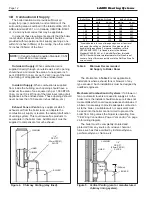

Temperature Rise

15°F

8°C

20°F

11°C

25°F

14°C

Size

Flow Rate

Headloss

Flow Rate

Headloss

Flow Rate

Headloss

gpm

l/s

ft

m

gpm

l/s

ft

m

gpm

l/s

ft

m

50

5.3

0.3

0.3

0.1

4.0

0.3

0.2

0.1

3.2

0.2

0.1

0.1

75

8.0

0.5

0.6

0.2

6.0

0.4

0.3

0.1

4.8

0.3

0.2

0.1

100

10.7

0.7

1.3

0.4

8.0

0.5

0.7

0.2

6.4

0.4

0.5

0.2

125

*

13.3

0.8

2.2

0.7

10.0

0.6

1.3

0.4

8.0

0.5

0.8

0.2

150

*

17.0

1.1

2.5

0.8

12.8

0.8

1.8

0.5

10.3

0.6

1.2

0.4

200

*

22.8

1.4

5.0

1.5

17.0

1.0

3.1

0.9

13.7

0.9

1.9

0.6

*

Models 125-200 ship with a low loss header with integral pump, so a separate boiler pump does not need to be sized or fi eld-supplied.

NOTES:

1. Shaded area represents typical temperature rise.

2. gpm = water fl ow in gallons per minute.

3. l/s = water fl ow in liters per second.

4. ft = pressure drop (headloss) through the boiler in feet of water.

5. m = pressure drop (headloss) through the boiler in meters of water.

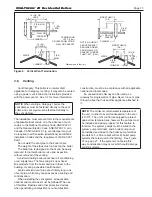

Sizing

Data

Heating Capacity AFUE % Water Gas

Input

Nat Gas

Conn. Conn.

Size

MBTU/h

kW

MBTU/h

kW

%

in.

in.

50

50

14.7

42

12.6

84 1-1/4 3/4

75

75

22.0

63

18.8

84 1-1/4

3/4

100

100

29.3

84

24.9

84 1-1/4

3/4

125

125

36.6

105

31.1

84 1-1/4

3/4

150

150

44.0

126

37.2

84 1-1/4

3/4

200

199

58.3

168

49.2

84 1-1/4

3/4

WARNING

This unit must be electrically grounded in accordance

with the requirements of the authority having jurisdiction

or, in the absence of such requirements, with the latest

edition of the National Electrical Code, ANSI/NFPA 70,

in the U.S. and with the latest edition of CSA C22.1

Canadian Electrical Code, Part 1, in Canada. Do not rely

on the gas or water piping to ground the metal parts of

the boiler. Plastic pipe or dielectric unions may isolate the

boiler electrically. Service and maintenance personnel,

who work on or around the boiler, may be standing on

wet floors and could be electrocuted by an ungrounded

boiler. Electrocution can result in severe injury or death.

7.A Safety Warnings

Single pole switches, including those of safety

controls and protective devices, must not be wired

in a grounded line.

All internal electrical components have been

pre-wired. No attempt should be made to connect

electrical wires to any other location except the

terminal blocks and line voltage hanging leads /

pigtail.

7.B Main Power, 120V

Main Power Connection: This boiler has a set of wires

for the main power connection. They are located in

the area between the control bezel and the conduit

anchor plate. The black lead for 120V(H), the white for

120V(N) and a green lead provides an earth ground.

Appropriate service switches and circuit breakers need

to be installed prior to the boiler based on national and

local codes having jurisdiction. The size of the main

power supply should be determined by Table 7. This

table indicates the unit’s Full Load Amperage (FLA),

Maximum Overcurrent Protection and Minimum Circuit

Ampacity (MCA). An overcurrent protection value

should be selected based on these numbers.

NOTE: all units with Manufacturer recommended

and supplied boiler pumps may be powered using

the supplied voltage.

CAUTION

Label all wires prior to disconnection when

servicing controls. Wiring errors can cause

improper and dangerous operation.

ATTENTION

Au moment de l'entretien des commandes,

etiquetez tousles fils avant de les debrancher.

Les erreurs de cablage peuvent nuire au bon

fonctionnement et etre dangereuses.

CAUTION

Verify proper operation after operation servicing.

ATTENTION

S'assurer que l'appareil fonctionne adequatement

une fois l'entretien termine.

7.C

Outdoor Sensor

An optional outdoor sensor can be purchased for use

with the outdoor reset or thermal targeting features

that are built into the boiler's control system. (See the

Accessories List in Section 12.B on page 49). The

sensor must be installed in a shaded area, preferably

on the north side of the structure, and must be installed

above the highest expected snow line.

To use the outdoor sensor for warm weather shutdown

(WWSD) only: Connect sensor to WWSD and COM

terminals. The control will then operate in Economy

Mode settings using Thermal Targeting. It will also shut

the boiler off at outdoor temperatures higher than the

selected WWSD temperature.

To utilize Outdoor Reset: Connect the sensor to OAS

and COM Terminals. The control will then operate

based on the selected Outdoor Reset settings. It will

also shut the boiler off at outdoor temperatures higher

than the selected WWSD temperature.

Once the outdoor sensor is installed, see "8.C.1

Programming the Outdoor Sensors" on page 32 for

how to adjust the Outdoor reset using the controller.

M

INI-

T

HERM

JX

Residential Boilers

®