Page 69

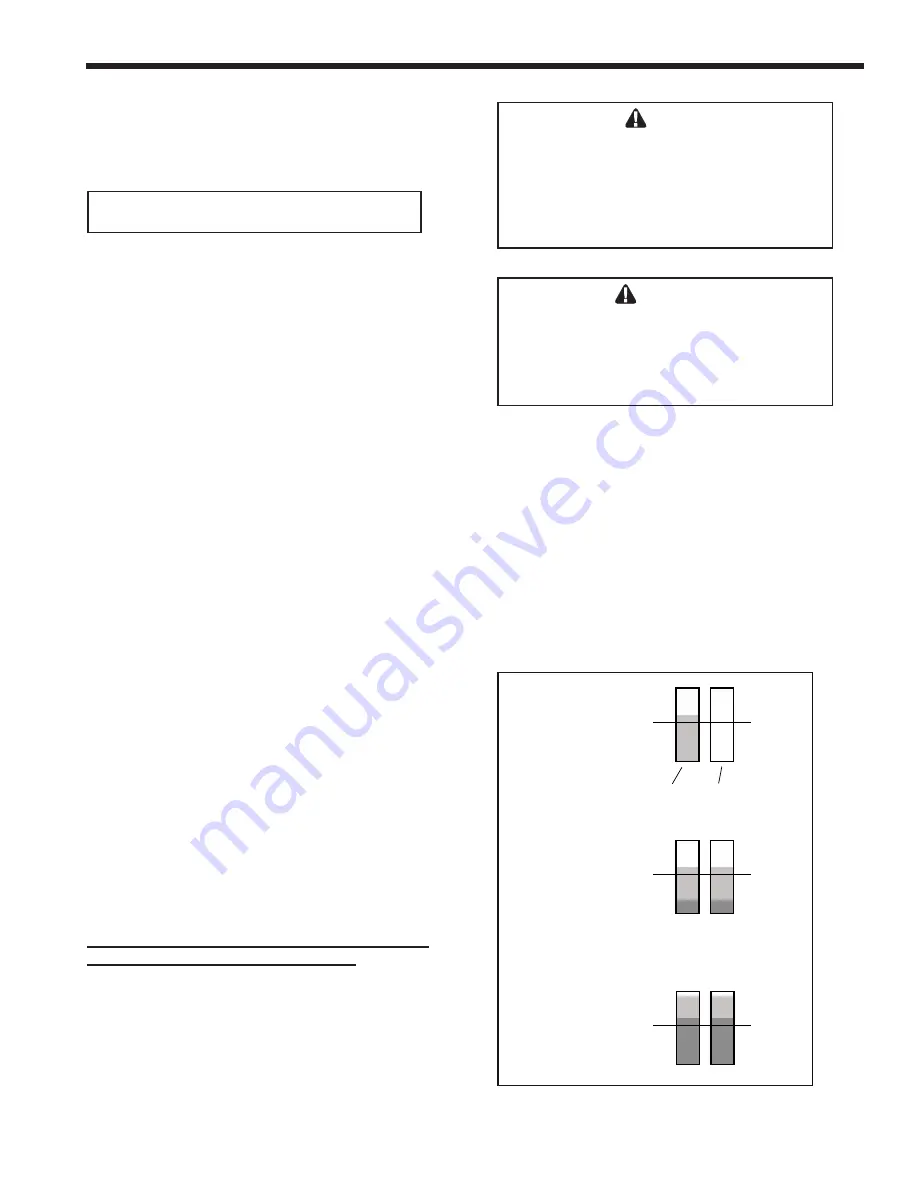

Figure 40.

Lead Lag Operation, 2 boilers.

Low demand -

The first boiler in

sequence fires at

less than 65%

First

boiler

Second

boiler

Demand increases -

Once the first boiler

reaches 65%,

the second boiler

switches on, and by

default, both modulate

together between 20%

and 65% (this can be adjusted up to 20% and

85

%).

Nearing max. demand -

Once both reach 65%,

then they are both

allowed to go over

65%

8.G.18.a

About Lead Lag Operation

You can cascade up to eight

(150 - 850 MBH) boilers or water heaters.

For wiring connections to Lead Lag,

see Figure 34 on page 48

About Lead Lag Operation -

If an installation includes two or more boilers,

they may be set up for “Lead Lag” operation. One

boiler will be set up as the “Leader”, and the others

will operate as “Followers.” Figure 41 shows an

installation with the Lead Lag Maximum of eight

(150-850 MBH) boilers. The boiler controllers

are connected in a “daisy chain” using a Modbus

connection.

A single System sensor is used to monitor the

demand for heat. The input from this sensor is used

by the Leader controller to control the modulation

rates of all of the operating boilers.

Lead Lag Modulation Cycle -

Note - We will explain the modulation cycle here,

in case you need to understand how the Lead Lag

system actually operates. If you are installing the

unit(s) and want to skip this section, just remember

that, as the heating demand increases, the Lead Lag

system puts more boilers on-line. As the heating

demand is reduced, the Lead Lag system shuts off

some of the boilers.

The signal from the System sensor is sent to the unit

operating as the Lead Lag Leader. A Run sequence

is initiated when the system temperature falls to the

Lead Lag Central Heat setpoint. (Actually this is the

LL CH setpoint less the On Hysteresis value. The

default setting for On Hysteresis is 5°F, but this is

adjustable.)

Notice that, when a boiler is operating as part of a

Lead Lag system, it does not use the normal CH

setpoint – it uses the special LL CH setpoint on the

Lead Lag Leader.

The unit acting as the Lead Lag Leader decides

which boiler is assigned to start first.

This

assignment is rotated across all of the available

boilers so that any one boiler does not run

significantly longer than the others. The Lead

Lag controller tracks the run times for all of the

boilers, and uses this to calculate the starting

order for the boilers. This means that each time

the system starts up, a different boiler may start

first.

Caution

You should set the Modbus addresses before

you connect the Modbus wiring. If the wiring

is attached before the Modbus addresses on

the controls are changed, there will be multiple

controls with the same address, and the system

will not work.

WARNING

If the Modbus addresses are not assigned

properly, the system could fail to operate

correctly, or it might operate in an unsafe

manner. This could lead to property damage,

personal injury or death.

•

When the Run sequence is initiated, the

boiler with the least amount of runtime will fire.

•

If the heating demand increases so that

the firing rate of that first boiler rises to your boiler

configurations Base Load Value

(see Figure 40

or Figure 42)

, the next boiler in the sequence will

start up and begin firing at 20 to 35% fan speed

(depending on your configuration). After this, the

entire configuration of boilers will modulate up

or down together, in reaction to the changes in

demand.

N

EO

T

HERM

Commercial Boilers and Water Heaters

Summary of Contents for Neotherm NTH

Page 4: ...LAARS Heating Systems...

Page 36: ...Page 36 Figure 22 Hydronic Piping Single Boiler Zoning with Circulators LAARS Heating Systems...

Page 52: ...Page 52 Figure 36 Ladder Diagram 7 H Ladder Diagram LAARS Heating Systems...

Page 100: ...Page 100 Parts Illustration 4 Internal Components Sizes 750 850 LAARS Heating Systems...

Page 102: ...Page 102 Parts Illustration 6 Gas Train Components Sizes 600 850 LAARS Heating Systems...