NeoTherm Boilers and Water Heaters

Page 119

12.7 analysis

The control system includes an Analysis branch

that can display the behavior over a period of time

for several different parameters: fan speed, outlet

temperature, inlet temperature, etc.

How to get there –

Home Page <Select icon> Status Summary Screen

<Details button> Any Configuration Screen <Analysis

button> Trend Analysis Screen

fig. 138 – analysis Setup Screen

To use this function, select the parameter you want

to track from the pull-down list. The system will

present a graph that tracks that variable.

fig. 139 – trend analysis Graph

The time scale can be adjusted by pressing the

Seconds button in the lower left-hand corner.

12.8 operating Sequence

Initiation

Each controller enters the Initiation sequence after

one of these conditions:

•

Initial power up

•

Voltage fluctuations vary +10% or -15%

•

Frequency fluctuations vary ±10%

•

The demand, limit control input, or TT signals

are interrupted during the prepurge period.

•

After the Reset button is pressed.

•

After a Fault is cleared using the displays.

The Initiation sequence also delays the boiler

demand from being energized and re-energized from

an intermittent AC line input or control input. If

an AC problem exists for more than 240 seconds, a

lockout will occur.

Start-Up Checks in a lead/lag System

For an explanation of Lead/Lag operation, see the

first part of Section 9. In this section, we will focus

on the aspects of Lead/Lag that might be helpful in

troubleshooting.

When a Lead/Lag system is first powered up, the

controller acting as the Lead/Lag Master goes

through a “synchronization” process. During

synchronization, the controller establishes

communications with each of the Slave controllers

via the Modbus link. The Slave controllers

download some setup parameters and operating

history information. (On a system with several

boilers, this phase can take several minutes.) If the

Master cannot establish communications with one of

the Slaves, it triggers a Hold or Lockout.

The Master also checks the status of each of the flap

valves. If the Master cannot determine whether a

flap valve is open or closed, or if it cannot locate the

correct number of flap valves, it triggers a lockout or

hold.

If the system passes the checks described above,

each of the individual controller and burner

combinations is free to operate in the normal

way. The self-check and firing sequence for each

individual controller and burner combination is

described in the following section.

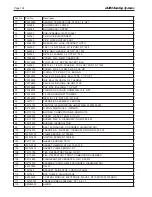

Summary of Contents for NTV1000

Page 2: ......

Page 35: ...NeoTherm Boilers and Water Heaters Page 31 Fig 20 Ladder Diagram...

Page 36: ...LAARS Heating Systems Page 32 Fig 21 Wiring Diagram...

Page 37: ...NeoTherm Boilers and Water Heaters Page 33...

Page 51: ...NeoTherm Boilers and Water Heaters Page 47 Fig 52 Connection Terminals...

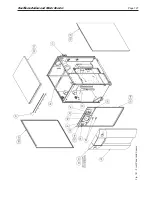

Page 130: ...LAARS Heating Systems Page 126 Fig 140 Machine Frame and Rear Panel 13 3 PARTS ILLUSTRATIONS...

Page 131: ...NeoTherm Boilers and Water Heaters Page 127 Fig 141 Front Panel and Covers...

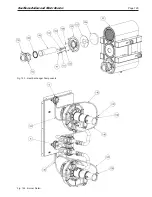

Page 132: ...LAARS Heating Systems Page 128 Fig 142 Burners and Combustion Chambers...

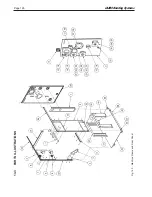

Page 134: ...LAARS Heating Systems Page 130 Fig 145 Electronic Components...

Page 135: ...NeoTherm Boilers and Water Heaters Page 131 Fig 146 Condensate Trap Fig 147 Control Bezel...

Page 136: ...LAARS Heating Systems Page 132 Fig 148 Flow Switch...

Page 137: ...NeoTherm Boilers and Water Heaters Page 133 This page intentionally left blank...