LAARS Heating Systems

Page 10

The condensate drain must be installed so as to

prevent the accumulation of condensate. When

a condensate pump is not used, the tubing must

continuously slope downward toward the drain with

no spiraling.

Consult local codes for the disposal method.

Caution

Condensate is mildly acidic (pH

=

5), and may

harm some floor drains and/or pipes, particularly

those that are metal. Ensure that the drain,

drainpipe, and anything that will come in

contact with the condensate can withstand the

acidity, or neutralize the condensate before

disposal.

Damage caused by failure to

install a neutralizer kit or to adequately treat

condensate will not be the manufacturer’s

responsibility.

3.2.3

Venting requirements Unique to

Canada

NeoTherm boilers and water heaters are Vent

Category IV appliances. Per the requirements of

CAN/CSA-B149.1, only BH vent systems can be

connected to these units and such vent systems,

either ULC S636 certified stainless steel or other

ULC S636 certified BH vent (eg. plastics) must

be installed per the vent manufacturer’s certified

installation instructions.

It is the responsibility of the appropriately licensed

technician installing this NeoTherm unit to use

ULC S636 certified vent material consistent with

the requirements as described in the Venting and

Combustion Air section.

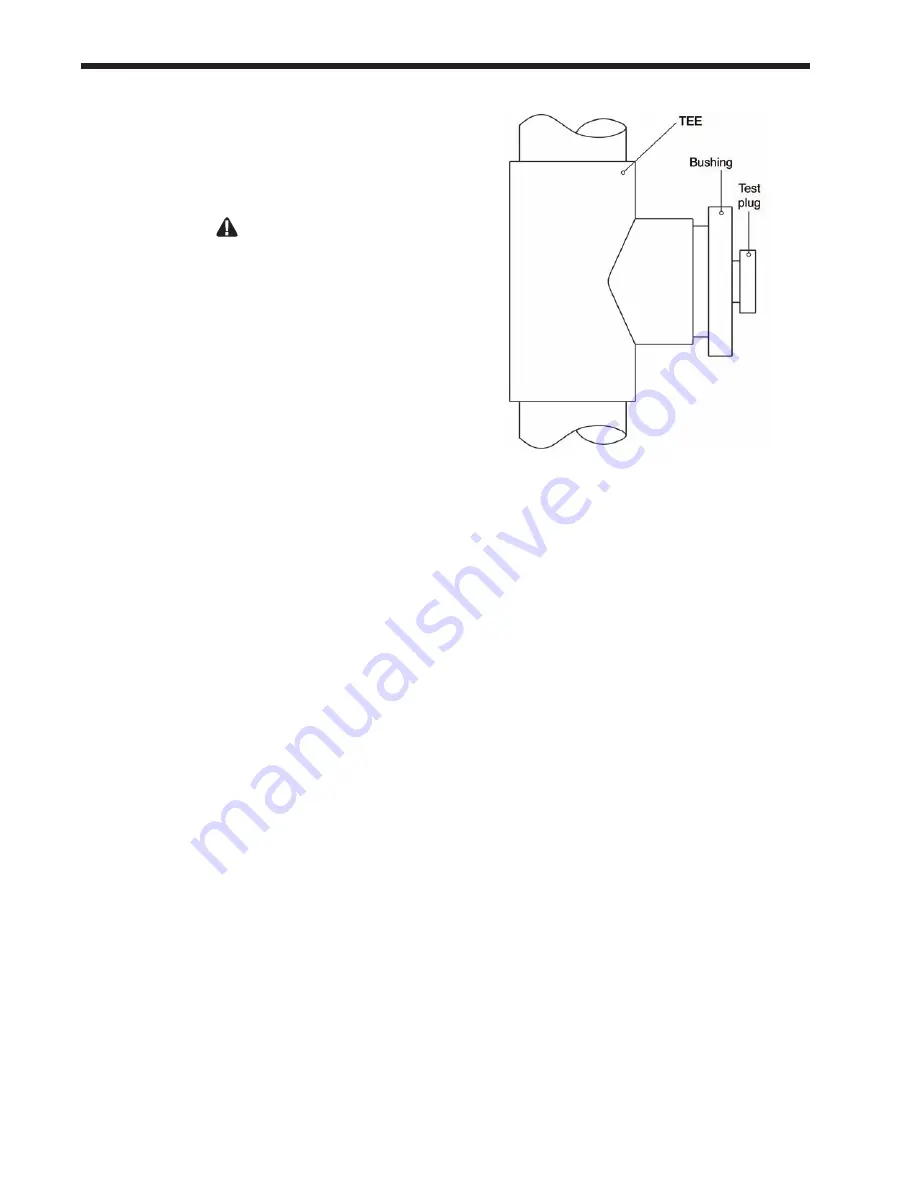

Flue Gas Sampling Port -

It is also the responsibility of the installer to ensure

that a flue gas sampling port is installed in the vent

system. This flue gas sampling port must be installed

near the flue connection of the NeoTherm unit:

within 2 feet of the flue connection. There is no flue

gas sampling port internal to the NeoTherm, so one

must be installed in the vent system external to the

NeoTherm unit. A flue gas sampling port available

as a component of the ULC S636 certified vent

system is preferred. However, if one is not available

with the certified vent system, Laars suggests using

a tee with the branch connection sized to allow for

insertion of a flue gas analyzer probe. The branch

connection must be resealable with a cap or other

means to ensure the vent system remains sealed.

(See Fig. 7.)

Consideration must be given to the placement

and orientation of the flue gas sampling port to

ensure that condensate is free to flow back into the

NeoTherm unit and not collect anywhere in the vent

system - including in the flue gas sampling port.

Exhaust Vent Terminal -

An exhaust vent terminal must be installed. If an

exhaust vent terminal is not available with the

certified vent system, Laars suggests the use of a

coupler fitting from the certified vent system into

which the vent terminal screen can be installed.

Be sure to install and terminate both vent and

combustion air pipes per the instructions in this

section.

3.3 locating the Vent and Combustion

air terminals

3.3.1 Side Wall Vent terminal

The appropriate Laars side wall vent terminal must

be used. The terminal must be located in accordance

with ANSI Z223.1/NFPA 54 and applicable

local codes. In Canada, the installation must be

in accordance with CSA B149.1 or .2 and local

applicable codes.

Consider the following when installing the terminal:

1. Figure 8 shows the requirements for

mechanical vent terminal clearances for the

U.S. and Canada.

fig. 7 - test Port

Summary of Contents for NTV1000

Page 2: ......

Page 35: ...NeoTherm Boilers and Water Heaters Page 31 Fig 20 Ladder Diagram...

Page 36: ...LAARS Heating Systems Page 32 Fig 21 Wiring Diagram...

Page 37: ...NeoTherm Boilers and Water Heaters Page 33...

Page 51: ...NeoTherm Boilers and Water Heaters Page 47 Fig 52 Connection Terminals...

Page 130: ...LAARS Heating Systems Page 126 Fig 140 Machine Frame and Rear Panel 13 3 PARTS ILLUSTRATIONS...

Page 131: ...NeoTherm Boilers and Water Heaters Page 127 Fig 141 Front Panel and Covers...

Page 132: ...LAARS Heating Systems Page 128 Fig 142 Burners and Combustion Chambers...

Page 134: ...LAARS Heating Systems Page 130 Fig 145 Electronic Components...

Page 135: ...NeoTherm Boilers and Water Heaters Page 131 Fig 146 Condensate Trap Fig 147 Control Bezel...

Page 136: ...LAARS Heating Systems Page 132 Fig 148 Flow Switch...

Page 137: ...NeoTherm Boilers and Water Heaters Page 133 This page intentionally left blank...