LAARS Heating Systems

Page 12

2. Vent terminals for condensing appliances or

appliances with condensing vents are

not

permitted to terminate above a public walkway,

or over an area where condensate or vapor

could create a nuisance or hazard.

3. Locate the vent terminal so that vent gases

cannot be drawn into air conditioning system

inlets.

4. Locate the vent terminal so that vent gases

cannot enter the building through doors,

windows, gravity inlets or other openings.

Whenever possible, avoid locations under

windows or near doors.

5.

Locate the vent terminal so that it cannot

be blocked by snow. The installer may

determine that a vent terminal must be

higher than the minimum shown in codes,

depending upon local conditions.

6. Locate the terminal so the vent exhaust does

not settle on building surfaces or other nearby

objects. Vent products may damage surfaces or

objects.

7. If the boiler or water heater uses ducted

combustion air from an intake terminal located

on the same wall, see Figures 9 and 10 for

proper spacing and orientation.

If the vent termination is located in an area exposed

to high winds, an optional PVC tee (the same

diameter as the vent pipe) may be used. The tee’d

vent termination offers greater protection from wind

related operating issues.

3.3.2 Side Wall Combustion air terminal

The LAARS side wall combustion air terminal

must be used when the heater takes air from a side

wall. (See Table 3.) Contact Laars for AL29-4C

termination fittings. Consider the following when

installing the terminal. (See Figures 9 and 10).

1. Do not locate the air inlet terminal near a

source of corrosive chemical fumes (e.g.,

cleaning fluid, chlorine compounds, etc.).

2. Locate the terminal so that it will not be subject

to damage by accident or vandalism. It must be

at least 7 feet ( 2.1 m) above a public walkway.

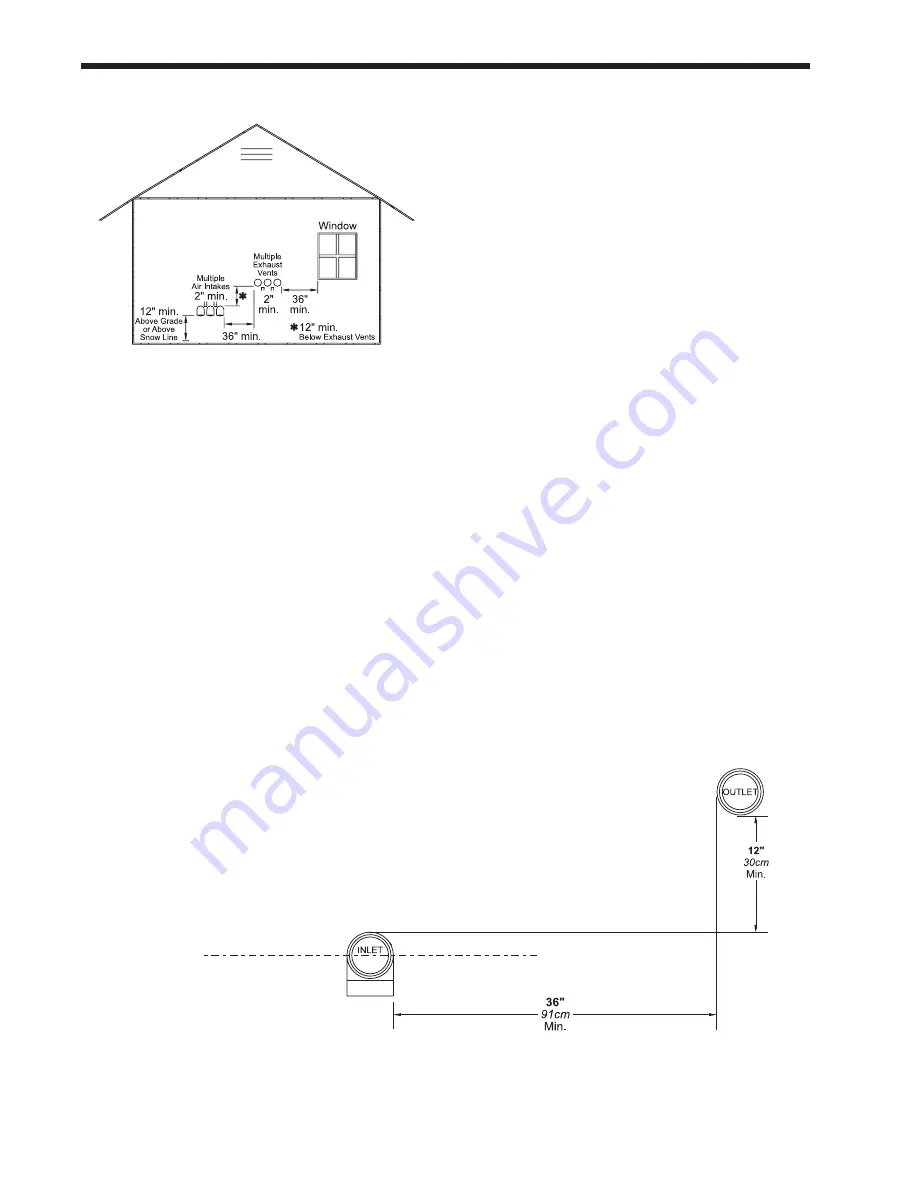

fig. 10 - minimum Venting Distance

IMPORTANT:

All terminals must be placed so that they remain at least

12” above the expected snow line. Local codes may have more specific

requirements, and must be consulted. Refer to the NFPA54 National Fuel

Gas Code and your local codes for all required clearances for venting.

fig. 9 - multiple Side-Wall terminals, air and Vent

Summary of Contents for NTV1000

Page 2: ......

Page 35: ...NeoTherm Boilers and Water Heaters Page 31 Fig 20 Ladder Diagram...

Page 36: ...LAARS Heating Systems Page 32 Fig 21 Wiring Diagram...

Page 37: ...NeoTherm Boilers and Water Heaters Page 33...

Page 51: ...NeoTherm Boilers and Water Heaters Page 47 Fig 52 Connection Terminals...

Page 130: ...LAARS Heating Systems Page 126 Fig 140 Machine Frame and Rear Panel 13 3 PARTS ILLUSTRATIONS...

Page 131: ...NeoTherm Boilers and Water Heaters Page 127 Fig 141 Front Panel and Covers...

Page 132: ...LAARS Heating Systems Page 128 Fig 142 Burners and Combustion Chambers...

Page 134: ...LAARS Heating Systems Page 130 Fig 145 Electronic Components...

Page 135: ...NeoTherm Boilers and Water Heaters Page 131 Fig 146 Condensate Trap Fig 147 Control Bezel...

Page 136: ...LAARS Heating Systems Page 132 Fig 148 Flow Switch...

Page 137: ...NeoTherm Boilers and Water Heaters Page 133 This page intentionally left blank...