LAARS Heating Systems

Page 62

A flap valve acts like a one-way valve or check valve.

If one burner in a boiler is operating, and the other

is not, one of the flap valves will close to prevent

exhaust air from moving backwards through the

burner that is not operating.

Before the Lead/Lag Master controller will allow

the system to operate, it must be able to determine

whether each of these flap valves is open or closed.

If the controller cannot find a signal from one of the

flap valves, the control system will act to prevent

backflow by energizing the blower of the control

with the bad flap valve. (The positive pressure from

the blower will prevent the exhaust air from moving

back through the burner.) If this cannot be done, the

Lead/Lag Master controller will not allow the whole

system to run. For this reason, it is important that all

of the flap valves be identified correctly.

Each controller in the system needs to know how

many controllers are included in the whole system.

You will need to enter this information in each of the

controllers separately.

WarnInG

If the flap valve identifications are not configured

correctly, this could cause the equipment to

malfunction. This could lead to personal injury or

death, and could damage the equipment. If the

configuration is not correct, the control system will

present an error – “HOLD 119 – Control Interaction

Fault” on the display, and will prevent the boiler(s)

from operating.

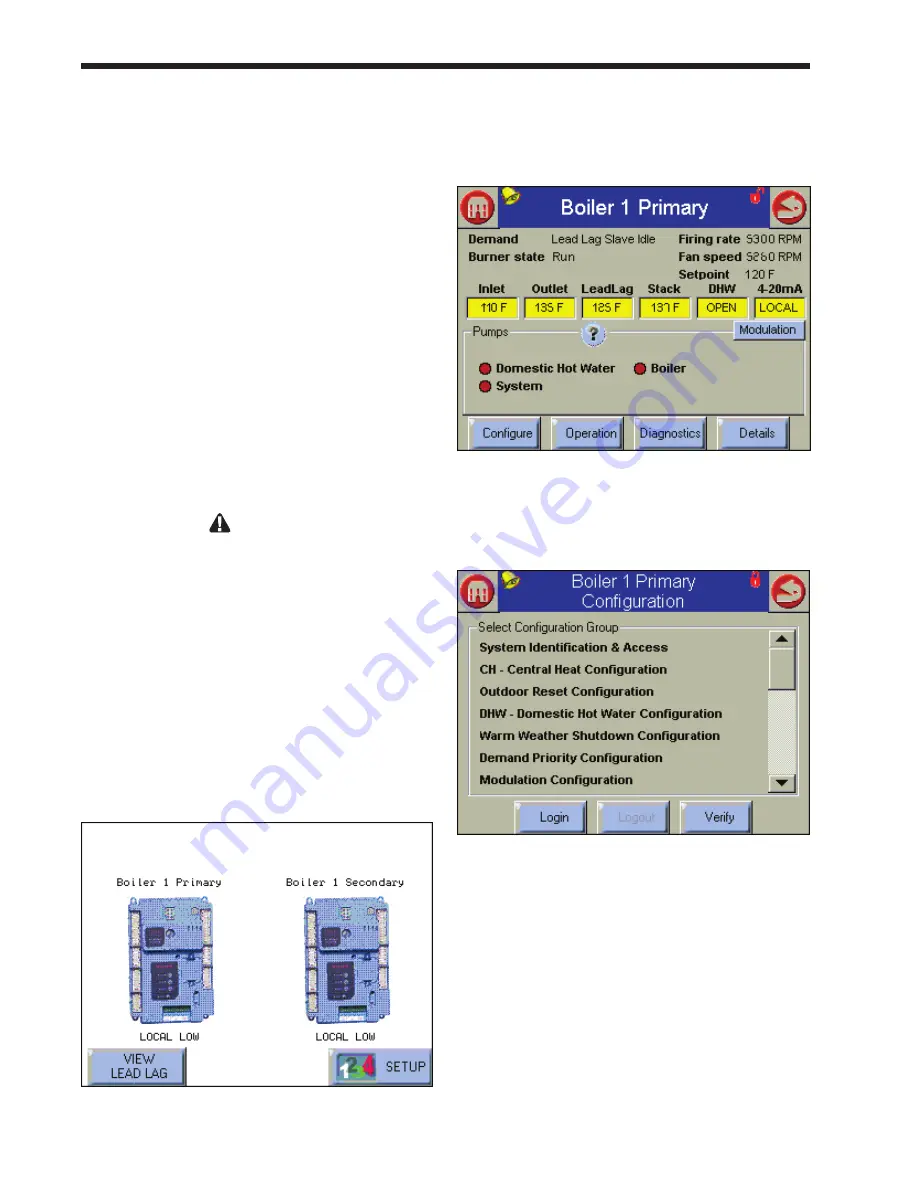

1. Let’s start by setting the Flap Valve ID for the

Primary control for Boiler 1. To do this, start

at the Home screen (Fig. 70). (To reach the

Home screen, press the Home icon in the upper

left corner of any screen.)

fig. 70 – Home Screen

2. Press the icon for the controller you want to

work with. The system will take you to the

Status Summary screen for that controller.

fig. 71 – Status Summary Screen

3. Press the Configure button. Figure 72 shows

the Configuration screen.

Fig. 72 – Configuration Screen

4. Scroll through the listing on the Configure

menu to Flap Valve Configuration, and select

that line. See Fig. 73.

Summary of Contents for NTV1000

Page 2: ......

Page 35: ...NeoTherm Boilers and Water Heaters Page 31 Fig 20 Ladder Diagram...

Page 36: ...LAARS Heating Systems Page 32 Fig 21 Wiring Diagram...

Page 37: ...NeoTherm Boilers and Water Heaters Page 33...

Page 51: ...NeoTherm Boilers and Water Heaters Page 47 Fig 52 Connection Terminals...

Page 130: ...LAARS Heating Systems Page 126 Fig 140 Machine Frame and Rear Panel 13 3 PARTS ILLUSTRATIONS...

Page 131: ...NeoTherm Boilers and Water Heaters Page 127 Fig 141 Front Panel and Covers...

Page 132: ...LAARS Heating Systems Page 128 Fig 142 Burners and Combustion Chambers...

Page 134: ...LAARS Heating Systems Page 130 Fig 145 Electronic Components...

Page 135: ...NeoTherm Boilers and Water Heaters Page 131 Fig 146 Condensate Trap Fig 147 Control Bezel...

Page 136: ...LAARS Heating Systems Page 132 Fig 148 Flow Switch...

Page 137: ...NeoTherm Boilers and Water Heaters Page 133 This page intentionally left blank...