NeoTherm Boilers and Water Heaters

Page 65

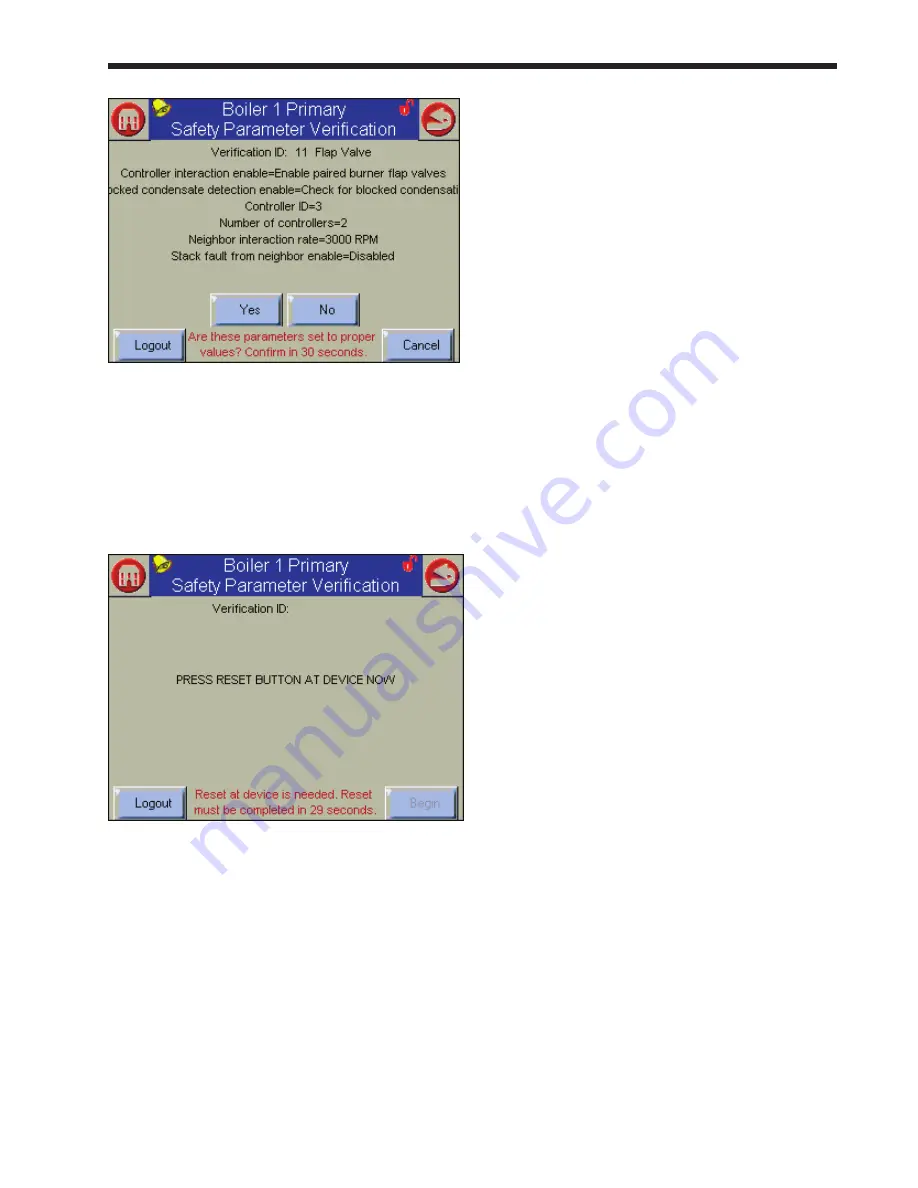

Fig. 78 – Safety Parameter Confirmation

Check the list carefully. Press Yes if all of

the parameters in the group have been entered

correctly.

11. The system will tell you to reset the control

system.

fig. 79 – Safety Parameter reset

You must press the Reset button within 30

seconds, or the verification will be cancelled.

12. At this point, you have set the flap valve

address for one of the controllers in the

boiler. The next job is to set the flap valve

identification for the other control on this

boiler. (In this example, this would be the

Secondary control on Boiler 1). Press the

Home button in the upper left-hand corner of

the display.

13. Press the icon for the Secondary control. Repeat

steps 3 through 12 for the Secondary control for

Boiler 1. (From Table 15, you can see that the

address for this control should be “2.”)

14. At this point, you have set the flap valve ID’s

for both controllers on one of the boilers.

Now you must repeat the process for all of the

controllers on each of the other boilers.

Job G – Disconnect Unused operator

Interfaces

Once a Lead/Lag system is set up and operating, the

control and monitoring functions will all be handled

from one Operator Interface – the one connected to

the boiler which includes the Lead/Lag Master. The

other Operator Interfaces will not have any function,

and should be disconnected from the system.

So that there is no confusion, we want to emphasize

this:

• The Modbus connections between the

controllers must remain connected. These

form the “daisy chain” which allows the Lead/

Lag Master to communicate with the rest of

the system. The Modbus connections use

connectors MB1 and MB2 on each controller.

Be sure all of the controllers remain connected

via MB1 and MB2.

• Also, do not disconnect the wiring to the

Operator Interface on the boiler which includes

the Lead/Lag Master.

In this section, we are talking just about the

connections between each unused Operator Interface

and the primary controller in its boiler.

1. Turn off the power to the boiler which has an

unused Operator Interface.

2. Open the front door to get access to the

electronics panel. The Primary controller is

located on the right. See Fig. 52.

3. On the Primary controller, find the connections

for MB2. See Fig. 19. There are two sets of

wires running to each MB2 connection. One

set of wires goes to the Operator Interface, and

the other set runs to the other controllers in the

system.

Disconnect just the three wires which

run to the operator interface.

4. Close the front door and turn on power to the

boiler.

Summary of Contents for NTV1000

Page 2: ......

Page 35: ...NeoTherm Boilers and Water Heaters Page 31 Fig 20 Ladder Diagram...

Page 36: ...LAARS Heating Systems Page 32 Fig 21 Wiring Diagram...

Page 37: ...NeoTherm Boilers and Water Heaters Page 33...

Page 51: ...NeoTherm Boilers and Water Heaters Page 47 Fig 52 Connection Terminals...

Page 130: ...LAARS Heating Systems Page 126 Fig 140 Machine Frame and Rear Panel 13 3 PARTS ILLUSTRATIONS...

Page 131: ...NeoTherm Boilers and Water Heaters Page 127 Fig 141 Front Panel and Covers...

Page 132: ...LAARS Heating Systems Page 128 Fig 142 Burners and Combustion Chambers...

Page 134: ...LAARS Heating Systems Page 130 Fig 145 Electronic Components...

Page 135: ...NeoTherm Boilers and Water Heaters Page 131 Fig 146 Condensate Trap Fig 147 Control Bezel...

Page 136: ...LAARS Heating Systems Page 132 Fig 148 Flow Switch...

Page 137: ...NeoTherm Boilers and Water Heaters Page 133 This page intentionally left blank...