Low Temperature Pennant

Page 7

SECTION 2.

Venting and Combustion Air

WARNING

For indoor installations, as an additional measure

of safety, Laars strongly recommends installation of

suitable Carbon Monoxide detectors in the vicinity of

this appliance and in any adjacent occupied spaces.

AVERTISSEMENT

Pour des installations intérieures, Laars

recommande fortement, comme mesure de sécurité

supplémentaire, l’installation de détecteurs de

monoxyde de carbone adaptés dans le voisinage

de l’appareil et dans chacune des pièces habitées

adjacentes.

2.1 Combustion Air

Pennant boilers and water heaters must have

provisions for combustion and ventilation air in

accordance with the applicable sections addressing

requirements for air for combustion and ventilation of

the National Fuel Gas Code, ANSI Z223.1. In Canada,

the applicable sections of the Natural Gas and Propane

Installation Code (CSA B149.1) must be followed. In

all cases any and all applicable local installation codes

must also be followed.

A Pennant appliance may receive combustion

air from the space in which it is installed, or it can be

ducted directly to the unit from the outside. Proper

ventilation air must be provided in either case.

2.1.1 Combustion Air From Room

In the United States, the most common

requirements specify that the space shall communicate

with the outdoors in accordance with method 1 or 2,

which follow. Where ducts are used, they shall be of

the same cross-sectional area as the free area of the

openings to which they connect.

Method 1

: Two permanent openings, one

commencing within 12 inches (30 cm) of the top

and one commencing within 12 inches (30 cm) of

the bottom, of the enclosure shall be provided. The

openings shall communicate directly, or by ducts,

with the outdoors or spaces that freely communicate

with the outdoors. When directly communicating

with the outdoors, or when communicating to the

outdoors through vertical ducts, each opening shall

have a minimum free area of 1 square inch per 4000

Btu/hr (5.5 square cm/kW) of total input rating of all

equipment in the enclosure. When communicating to

the outdoors through horizontal ducts, each opening

shall have a minimum free area of not less than

1 square inch per 2000 Btu/hr (11 square cm/kW) of

total input rating of all equipment in the enclosure.

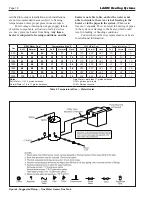

Table 3

shows data for this sizing method, for each

Pennant model.

Method 2

: One permanent opening, commencing

within 12 inches (30 cm) of the top of the enclosure,

shall be permitted. The opening shall directly

communicate with the outdoors or shall communicate

through a vertical or horizontal duct to the outdoors

or spaces that directly communicate with the outdoors

and shall have a minimum free area of 1 square inch

per 3000 Btu/hr (7 square cm/kW) of the total input

rating of all equipment located in the enclosure. This

opening must not be less than the sum of the areas of

all vent connectors in the confined space.

Other methods of introducing combustion and

ventilation air are acceptable, providing they conform

to the requirements in the applicable codes listed

above.

In Canada, consult local building and safety

codes or, in absence of such requirements, follow

CSA B149.1, the Natural Gas and Propane Installation

Code.

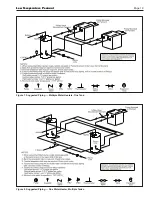

2.1.2 Intake Combustion Air

The combustion air can be taken through the

wall, or through the roof. When taken from the wall, it

must be taken from out-of-doors by means of the Laars

horizontal wall terminal (see

Table 2

). When taken

from the roof, a field-supplied rain cap or an elbow

arrangement must be used to prevent entry of rain

water (see

Figure 2

).

Use single-wall galvanized pipe, per

Table

4,

for the combustion air intake (see

Table 2

for

appropriate size). Route the intake to the heater as

directly as possible. Seal all joints with tape. Provide

adequate hangers. The unit must not support the

weight of the combustion air intake pipe. Maximum

linear pipe length allowed is 50 feet (15.2m). Three

elbows have been calculated into the 50-foot (15.2m)

Size

Each Opening*

Square inches

Square cm

500

125

807

750

188

1213

1000

250

1613

1250

313

2020

1500

375

2420

1750

438

2826

2000

500

3226

*Net Free Area in Square Inches /

Square cm

Area indicated is for one of two openings; one at floor level

and one at the ceiling, so the total net free area could be

double the figures indicated.

This chart is for use when communicating directly with the

outdoors. For special conditions and alternate methods, refer

to the latest edition of ANSI Z223.1.

Note:

Check with louver manufacturers for net free area of

louvers. Correct for screen resistance to the net free area

if a screen is installed. Check all local codes applicable to

combustion air.

Table 3. Combustion Air Openings.

Summary of Contents for Pennant PNCH

Page 23: ...Low Temperature Pennant Page 23 Figure 12 Ladder Diagram Sizes 500 1000 ...

Page 24: ...LAARS Heating Systems Page 24 Figure 13 Ladder Diagram Sizes 1250 2000 ...

Page 25: ...Low Temperature Pennant Page 25 Figure 14 Wiring Diagram Sizes 500 1000 ...

Page 26: ...LAARS Heating Systems Page 26 Figure 15 Wiring Diagram Sizes 1250 1500 ...

Page 27: ...Low Temperature Pennant Page 27 Figure 16 Wiring Diagram Sizes 1750 2000 ...