LAARS Heating Systems

Page 6

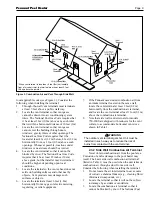

1.6 Locating Heater with Respect to Pool

System Loop

For the best results, the Pennant should be

located within 15 feet (4.6m) of the pool system loop.

The pump is sized for 30 feet (9.1m) of piping.

If the appliance must be installed with longer

piping runs, then larger diameter piping shall be used.

Consult the factory for assistance.

1.7 Locating Appliance for Correct

Horizontal Vent/Ducted Air Distance

From Outside Wall

The forced draft combustion air blower/blowers

in the appliance has/have sufficient power to pull air

and vent properly when the following guidelines for

horizontal air and vent are followed (see Table 1).

NOTE:

On all model sizes, the vent collar size is larger

than the size of the vent pipe that can be used. Vent

collar size and horizontal pipe diameters can be found

in Table 1. The larger vent collar size is to

accommodate Category I (vertical) vent systems.

NOTE:

When located on the same wall, the Pennant

combustion air intake terminal must be installed a

minimum of 12" (30cm) below the exhaust vent

terminal and separated by a minimum of 36 inches

(91cm) horizontally.

The air intake terminal must be installed high

enough to avoid blockage from snow, leaves and other

debris. Never obtain combustion air from the pool

area. Corrosion of and/or damage to the pool heater

may result.

SECTION 2.

Venting and Combustion Air

2.1 Combustion Air

Pennant pool heaters must have provisions for

combustion and ventilation air in accordance with

section 5.3, Air for Combustion and Ventilation, of the

National Fuel Gas Code, ANSI Z223.1, or Sections

7.2, 7.3 or 7.4 of CAN/CGA B149, Installation Codes,

or applicable provisions of the local building codes.

A Pennant appliance may receive combustion air

from the space in which it is installed, or it can be

ducted directly to the unit from the outside.

Ventilation air must be provided in either case. Never

obtain combustion air from the pool area. Corrosion of

and/or damage to the pool heater may result.

2.1.1 Combustion Air From Room

In the United States, the most common

requirements specify that the space shall communicate

with the outdoors in accordance with method 1 or 2,

which follow. Where ducts are used, they shall be of

the same cross-sectional area as the free area of the

openings to which they connect.

Method 1

: Two permanent openings, one

commencing within 12 inches (30 cm) of the top and

one commencing within 12 inches (30 cm) of the

bottom, of the enclosure shall be provided. The

openings shall communicate directly, or by ducts, with

the outdoors or spaces that freely communicate with

the outdoors. When directly communicating with the

outdoors, or when communicating to the outdoors

through vertical ducts, each opening shall have a

minimum free area of 1 square inch per 4000 Btu/hr

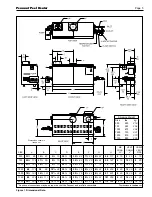

REQUIRED

RECOMMENDED

APPLIANCE

CLEARANCE FROM

SERVICE ACCESS

SURFACE

COMBUSTIBLE MATERIAL

CLEARANCE

inches

cm

inches

cm

Left Side

1

2.5

24

61

Right Side

1

2.5

24

61

Top

1

2.5

12

30

Back

1

2.5

**

12**

30**

Front

1

2.5

36

91

Vertical

(Category 1)

6*

15.2*

Vent

Horizontal

per UL1738 venting

(Category 3)

system supplier’s

Vent

instructions

*1" (2.5cm) when b-vent is used.

**When vent and/or combustion air connects to the back,

recommended clearance is 36" (91cm).

Table 2. Clearances.

BOILER

EACH OPENING*

SIZE

SQUARE INCHES

SQUARE CM

500

125

807

750

188

1213

1000

250

1613

1250

313

2020

1500

375

2420

1750

438

2826

2000

500

3226

*Net Free Area in Square Inches / Square cm

Area indicated is for one of two openings; one at floor level and

one at the ceiling, so the total net free area could be double the

figures indicated.

This chart is for use when communicating directly with the

outdoors. For special conditions and alternate methods, refer to

the latest edition of ANSI Z223.1.

Note:

Check with louver manufacturers for net free area of

louvers. Correct for screen resistance to the net free area if a

screen is installed. Check all local codes applicable to

combustion air.

Table 3. Combustion Air Openings.

Summary of Contents for Pennant PNCP 1000

Page 28: ...LAARS Heating Systems Page 28 Figure 9 Sheet Metal Components...

Page 29: ...Pennant Pool Heater Page 29 Figure 10 Internal Components...

Page 32: ...LAARS Heating Systems Page 32 Figure 13 Pennant 1250 2000 Ladder Diagram...

Page 33: ...Pennant Pool Heater Page 33 Figure 14 Pennant 500 1000 Wiring Schematic...

Page 34: ...LAARS Heating Systems Page 34 Figure 15 Pennant 1250 2000 Wiring Schematic...

Page 35: ...Pennant Pool Heater Page 35 Figure 16 Field Wiring PNCP 500 1000...